Energy Storage

Craig Tropea

Solar

Jonathan Lwowski

Solar

Steve Macshane, CESSWI

Hypercharge Networks Corp. (TSXV: HC; OTC: HCNWF;FSE: PB7) (the “Company” or “Hypercharge”), a leading, smart electric vehicle (EV) charging solutions provider and network operator, is pleased to announce the launch of Hypercharge Halo, a new Level 2 EV charging station for multi-family, commercial, and workplace applications. Combining powerful performance, durable construction, and intuitive design, Hypercharge Halo offers signature reliability and flexible charging for property owners and operators seeking next-generation EV charging solutions.

Unveiled at the EV & Charging Expo 2025 in Toronto, ON, Hypercharge Halo is on display throughout the event for attendees to experience in person.

“Property owners are looking for charging solutions that combine smart design with long-term value,” said David Bibby, President and CEO of Hypercharge. “Hypercharge Halo is designed with durability, flexibility, and reliability at its core, making it easy to integrate EV charging into residential and commercial spaces, today and into the future.”

Smart, Durable, and Future-Ready

Engineered for flexibility, Hypercharge Halo offers:

Built for All Environments

Designed to withstand diverse installation environments, Hypercharge Halo features IP65-rated dust and water protection and IK08 impact resistance, making it suitable for both indoor and outdoor applications. Its compact, modern form factor seamlessly integrates into a range of property types, delivering high-performance charging without compromising on aesthetics.

Serviceable and Sustainable

Hypercharge Halo is built with modularity in mind. Key components can be serviced or upgraded in the field, extending the station’s lifecycle and reducing long-term maintenance costs for property owners.

Hypercharge Halo is now available for order to commercial, residential, and workplace customers across North America. For more information about the Hypercharge Halo Level 2 EV Charging Station, visit: https://hypercharge.com/solutions/level2/halo/.

Hypercharge Networks | https://hypercharge.com/

.jpg)

Viridi, the industry leader in fail-safe battery energy storage systems (BESS), together with Soteria Battery Innovation Group, hosted a high-impact live demonstration event—"The No Heat Zone: Battery Storage Redefined"—drawing industry leaders, first responders, and safety officials from across the country to Viridi’s 42-acre Renewable Energy Center of Excellence in Buffalo.

The event featured a compelling series of live battery burn demonstrations, keynote addresses from the Fire Department of the City of New York (FDNY) safety experts, hands-on tours, and deep dives into next-generation anti-propagation battery technologies—technologies designed to eliminate thermal runaway, the leading cause of lithium-ion battery fires.

.jpg)

The highlight of the event was the live demonstration of Viridi’s fail-safe BESS, which withstood thermal challenges without flame propagation—showcasing its unique ability to contain failure without triggering system-wide risk.

Live Demo Results: Raising the Bar for Battery Safety

Tests 1 & 2 – Conventional Packs:

Two standard battery packs without anti-propagation features were intentionally pushed into thermal runaway. As expected, the initial failure triggered cell-to-cell propagation, resulting in heat spreading throughout the entire module.

Test 3 – Viridi-Engineered Pack:

Viridi triggered the same failure in one of its own packs—engineered with proprietary thermal isolation and anti-propagation barriers. The result: complete containment. The incident remained isolated to a single cell with no secondary reactions, validating Viridi’s passive safety architecture.

“Today wasn’t just about showing what’s possible—it was about proving it,” said Jon M. Williams, CEO of Viridi. “These tests show the power of our design in limiting thermal events to a single point of origin. We’re setting a new standard for battery safety that allows clean energy to scale—safely and without compromise. If you want to bring storage into dense, occupied spaces, this is how you do it—without shortcuts.”

As lithium-ion batteries become more common in everything from e-bikes to commercial buildings, the risks are growing harder to ignore: New York City recorded 277 lithium-ion battery-related fires in 2024 alone—and that number is still climbing. The volume of incidents underscores an urgent need for next-generation battery technologies that go beyond traditional fire suppression and prioritize prevention by design.

“Viridi's technology is a game-changer,” said Brian Morin, CEO of Soteria Battery Innovation Group. “Battery fires are rare, but they are also unpredictable, immediate and ferocious, which carries significant risk. Their technology dramatically reduces the risk profile, giving us a path to much safer energy storage for all the applications that improve our daily lives."

Attendees also heard from FDNY safety leaders John Cassidy and John Orlando, who emphasized the importance of testing new technologies in real-world conditions and the urgent need to bring fail-safe solutions to the frontline of building, infrastructure, and emergency planning.

“When it comes to battery fires, every second counts—and every layer of safety matters,” said Lt. John Cassidy of the FDNY. “I’m glad to support the safety and education of first responders by sharing my experience responding to lithium-ion battery incidents in New York City.”

Viridi’s technology is already being deployed in commercial and municipal buildings, manufacturing facilities, and high-traffic environments where traditional battery systems are too risky to install. Unlike conventional systems, Viridi’s solution requires no additional HVAC, fire suppression, or construction retrofits—a breakthrough for both cost and code compliance.

With national attention growing around battery fire risk in both stationary and mobile applications, “The No Heat Zone” signals a critical shift in how the industry thinks about scalable, sustainable, and safe energy storage.

Viridi | www.viridiparente.com

Soteria Battery Innovation Group | www.soteriabig.com

Summit Ridge Energy (SRE), Virginia’s leading solar developer, announced the energization of its Scenic Farms Shared Solar Project, a 4.1-megawatt solar installation located in Rockingham County, VA. The project is part of the Commonwealth’s expanded Shared Solar program, which provides Dominion Energy Virginia customers with broader access to solar energy bill credits—without requiring them to install panels on their own homes.

State officials, including Deputy Secretary of Commerce & Trade Maggie Beal and House of Delegates Majority Leader Charniele Herring, joined Summit Ridge leadership, key investors, and community partners to mark the official opening of the site.

The Scenic Farms Solar Facility is part of a portfolio of 25 projects that make up Summit Ridge’s 100 MW footprint in Virginia—positioning the company as the largest developer in Virginia and expanding access to locally generated energy. The Arlington-based company is now the owner and operator of nearly half of all capacity in the Virginia Shared Solar Program.

“The Summit Ridge team is proud to call Virginia home, and even prouder to play a role in meeting the Commonwealth’s growing energy needs. As Virginia has expanded its Shared Solar policy, we’ve had the opportunity to scale our efforts in tandem—now owning and operating 100 MW of projects across the state,” said Steve Raeder, Chief Executive Officer at Summit Ridge. “We’re committed to supplying locally generated power to Virginians while continuing our investment in the state.”

The construction and operation of this project and others in development represent Summit Ridge’s $250 million investment in Virginia—providing more than 1,000 jobs for construction workers, vendors, and local businesses. That investment is supported by Summit Ridge’s joint venture with Osaka Gas USA Corporation, with construction financing led by MUFG, a leading global financial group.

“It means a lot to know that this land is continuing to support our community—not only by producing food, but also by generating local energy,” said Leroy Heatwole of Scenic L Farms, the landowner where the solar facility is located. “We’re proud to still be raising poultry and growing wheat here, while also supporting the local education system and contributing to energy savings and economic growth. It’s an honor to be part of something that gives back and builds a legacy for my children and grandchildren.”

Once operational, the Scenic Farms site alone is expected to generate over 6.5 million kWh annually, delivering meaningful energy savings to over 600 local subscribers. Summit Ridge's fleet of assets will reduce energy costs for nearly 16,000 Virginia households once energized.

This significant development underscores Summit Ridge’s commitment to improving grid stability, boosting local economies, and providing tax benefits to the community. The Scenic Farms development reflects a growing interest in shared solar across the region, as consumers, policymakers, and businesses seek locally generated energy that expands America’s Energy Independence and long-term grid resilience.

Residential customers located within Dominion Energy service territory will be able to subscribe and benefit from this project with bill credits beginning in the summer of 2025. Virginia residents interested in enrolling in the state’s Shared Solar Program can get more information about subscribing by reaching out to Summit Ridge’s partner, Perch Energy, which recently merged with Arcadia’s community solar business.

Summit Ridge Energy | srenergy.com

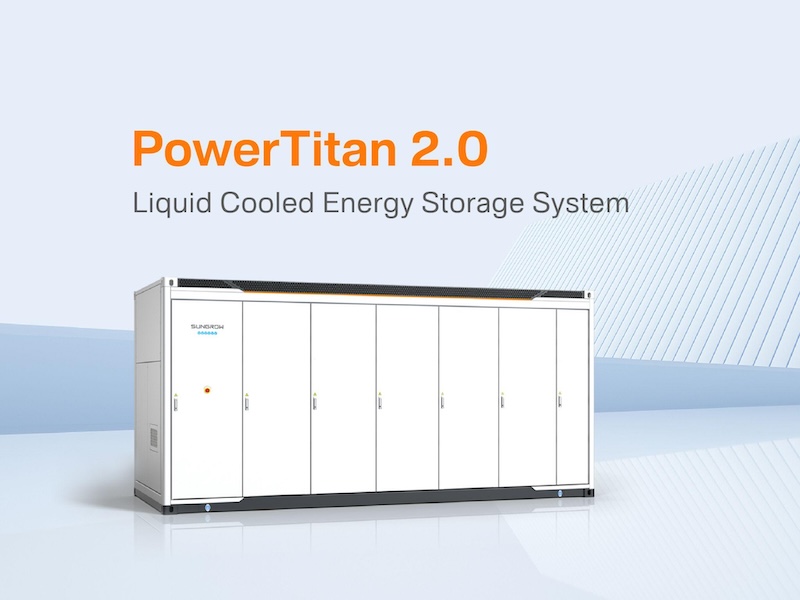

Sungrow, a global leader in clean energy technology, announced that its next-generation liquid-cooled battery energy storage system, PowerTitan 2.0, has received both TM-2 approval and a Certificate of Approval (COA) from the New York City Fire Department. The certification clears the way for deployment of the lithium-ion system within New York City — one of the most safety-conscious and technically demanding urban markets in the United States.

“This certification affirms that PowerTitan 2.0 meets the highest standards for fire safety and system integrity,” said Hank Wang, president of Sungrow Americas. “With power demands expected to increase dramatically in New York, we’re proud to offer customers a proven solution that is ready for immediate deployment across utility-scale storage, commercial and industrial sites, and dense urban environments.”

The Fire Department’s TM-2 and COA process is required for any energy storage system installed within New York City, and includes an extensive series of fire safety evaluations, technical design reviews, and third-party test reports. Approval typically involves coordination with engineers, first responders, and fire safety authorities, making it one of the most stringent municipal certification processes in the country.

Sungrow’s second-generation utility-scale battery energy storage system, now certified for use in New York City.

The 5MWh PowerTitan 2.0, comparable in size to a shipping container, is the successor to the original PowerTitan 1.0, which received New York City certification in 2023. The new model introduces a fully pre-integrated, plug-and-play architecture that simplifies installation and accelerates project timelines. It also includes engineering advancements that enhance thermal performance, rack-level control, and system-wide fire protection.

For example, a liquid-cooled thermal management system maintains cell-level stability, with a temperature variance of less than 2.5°C across racks. That, when combined with the system’s rack-level control — improves system balance, performance, usable capacity and reduces mismatch during operation. A built-in automation handles coolant refilling and state-of-charge balancing, while fire protection is reinforced through arc extinguishing technology, fire-resistant partitions, and optional integrated sprinklers.

This announcement follows Sungrow’s successful completion of the world’s largest burn test to date of a utility-scale battery energy storage system, in June 2024, conducted in partnership with national safety agencies and third-party observers. The large-scale fire test (LSFT) subjected PowerTitan 2.0 to extreme fire conditions for nearly 26 hours to validate its containment, suppression, and emergency response features — setting a new benchmark for BESS safety across the industry.

“Our engineering team designed PowerTitan 2.0 from the ground up to deliver both performance and peace of mind,” said Bryce Laber, manager of ESS product engineering at Sungrow. “We’ve integrated safety at every level so that project developers can focus on delivering reliable energy to the grid.”

The PowerTitan 2.0 plug-and-play BESS uniquely pre-integrates all internal components — including the batteries, string PCSs, BMS, thermal management, and fire suppression systems — within a 20-foot container for easy installation, improved adaptability, and high performance.

Now, with local electricity demand poised to surge, Sungrow’s storage solutions can serve a broader set of projects pursuing behind-the-meter resilience, front-of-the-meter grid services, and compliance with clean energy mandates.

A white paper with more on the innovative systems inside the PowerTitan 2.0 battery system can be found here.

Sungrow North America | https://us.sungrowpower.com

DEPCOM Power was hired by a local utility to design, build and maintain a Battery Energy Storage System (BESS) that delivers 800 megawatt hours of stored solar and wind power to some 42,000 customers. This 10-acre project consists of highly modified 20-foot ISO containers with Lithium Iron Phosphate (LFP) batteries which are connected to centralized inverters, and are then interconnected to a transmission substation. The batteries require a substantial amount of auxiliary power, primarily for temperature control, so an expansive 480V 3P AC network is utilized to distribute power to each of the 360 battery containers. The auxiliary protection components consist of a network of switchboards and panelboards which all contain Siemens 3WA and 3VA line circuit breakers. The batteries must run at an optimal temperature range, requiring an HVAC system to keep them from overheating.

The HVAC system has to operate continuously. If power from the grid goes out, an auxiliary switchboard engages a generator for backup power. DEPCOM Power contracted North Carolina-based electrical switchboard provider EPEC and its agent, ReBoSS, to deliver a highly customized auxiliary power switchboard system to control the HVAC and monitor the current flowing to the batteries. This auxiliary power system is made up of a network of switchboards and panelboards that are each equipped with a fleet of Siemens 3VA6 molded case circuit breakers and two Siemens 3WA main air breakers, both of which are assembled at the Siemens Mayfield plant in Grand Prairie, TX.

Adding Grid Stability Expected to reach completion in summer 2025, the project is a 200-megawatt standalone energy storage project delivering over 800 megawatt hours of energy. Its primary purpose is to provide grid stability by storing excess solar power and distributing it after sundown to nearby homes when they need it most. The project delivers enough electricity to keep about 42,000 homes powered for four hours after sundown.

Solar energy is harnessed during the morning and early afternoon, when the sun is strongest. “Excess solar that is produced during the daytime is utilized to charge these batteries,” said Mark Sauls, Vice President of Sales and Operations for EPEC Solutions. “And then after the sun goes down, the batteries discharge and you have an extra four hours of power.”

This BESS project fits into the local utilities aggressive sustainability strategy. The utility is striving for net zero direct greenhouse gas emissions by 2050. The project is one of the largest battery storage systems in the American Southwest, using its storge capability to add stability and reliability to energy sources that are inherently intermittent.

“This site is actually located relatively close to a population center, so it's available – and not transmission constrained – to deliver power to the city,” said Walker Wentzler, Sr. Director of Electrical Engineering at DEPCOM Power. “It is really making up for those peaks and valleys when people get home and turn on all their appliances.”

Maintaining a Steady Operation Energy arrives at the project’s BESS through the local power distribution network. It is then stored in the lithium iron phosphate batteries. These batteries leverage newer technology that delivers longer life and make them safer to operate. “The batteries need to stay cool or within a relatively finite temperature band for them to operate for their entire life and continue performing,” said Wentzler.

The liquid heating and cooling system controls the temperature of the circulating fluid within the battery modules to keep the battery cells in ideal temperature range – and should the utility power go out, the cooling system must continue operating. That’s where the EPEC switchboard comes in, providing power to the HVAC and maintaining the batteries in a steady state.

DEPCOM Power turned to EPEC for the auxiliary power switchboard for a number of reasons. The system is highly flexible and customizable and delivers the functionality the facility needed while keeping people safe by reducing arc flash, said Wentzler.

The switchboards were assembled by EPEC’s manufacturing arm, QT Corp., and delivered by ReBoSS. They are double-ended, low-voltage units with two electrically switchable Siemens 3WA main breakers and 14 3VA6 circuit breakers in each switchboard.

“The dual 3WA main breakers have a purpose,” said Drew Vermillion, president of ReBoSS. “We have a backup breaker in case the substation goes down. The second main breaker is then powered by a secondary utility feed to keep the HVAC running on the battery storage system. The main breakers feed the 3VA6 molded case circuit breakers that feed out to auxiliary distribution panels and the HVAC systems.”

The Siemens Advantage “EPEC has equipped its switchboards with Siemens circuit breakers for years. Units like the 3VA6 offer a host of features ideal for grid stability projects, starting with build quality," Sauls said. “The reliability, efficiency, and communication capabilities of the 3VA6 molded case circuit breaker far exceeds other big-name competitors.”

For this project, EPEC used its innovative solar-specific UL 891 dead front switchboard, which minimizes cable sizes, reducing implementations by 40%. Thanks to the reduction in cabling, the switchboard is more cost-effective and quicker to install.

This project is another example of how Siemens technologies are enabling its customers to be energy diverse, efficient and resilient.

The Siemens 3VA6 molded case circuit breakers deliver a host of benefits:

Electronic Tripping

3VA6 breakers are equipped with electronic tripping, which is preferable to thermal magnetic circuit breakers in BESS applications. BESS projects often operate in harsh environments. In Arizona, temperatures can rise well above 100 degrees Fahrenheit for extended periods. Because thermal magnetic circuit breakers are very susceptible to ambient temperatures, nuisance tripping can become an issue. But that does not occur with electronic tripping.

Built-in Metering

DEPCOM Power needed a switchboard with metering capabilities in order to monitor the feeder circuit breakers and measure the auxiliary power consumption of the batteries. 3VA6 circuit breakers have built-in metering capability, making it possible to remotely monitor the current. “Each 3VA6 breaker actually monitors the current and lets the owner know how much current is flowing out to the panel board, which then flows to the HVAC of the battery containers. By monitoring the current of that 3VA6, they're actually able to determine the health of the HVAC system and therefore the health of the overall plant,” Sauls said.

Monitoring capabilities were especially important, Wentzler said. “This asset is going to be largely unmanned and operated from a remote standpoint, and so one of the options that we leveraged with the 3VA line was basically a bolt-on addition to those breakers.” This enables remote operators to track consumption at a very granular level and take action when troubleshooting is necessary, he said.

• Flexibility and Safety The 3VA6 molded case circuit breakers delivered the flexibility and safety required for this BESS project. “They have all the latest features like the arc energy reduction maintenance switch, and then they have the built-in safety codes that OSHA (Occupational Safety and Health Administration) and the NEC (National Electric Code) require,” Vermillion noted.

To keep people safe, it was crucial to have molded case circuit breakers with a high short circuit breaking capacity, according to Wentzler. The breakers allow technicians to adjust parameters as needed and reduce arc flash “There's a pretty high peak load for auxiliary consumption for the HVAC and chillers to keep the systems cool, so what you wind up with on a system of this size is a very expansive low-voltage, 480-volt auxiliary distribution network. The 3VA line offers a lot of flexibility in being able to get to some very, very high levels of breaking current.”

Customization

The project required several customizations, which included designing a larger auxiliary panel board that handles larger cables and includes an external, lockable rotary operator for technicians to turn it on and off without opening the panel door.

In addition, the two Siemens 3WA main breakers allowed for customization that DEPCOM Power needed to automate and interlock the systems. “Being able to close and then interlock between the two main breakers with the Siemens continuous shunt trip was really key in being able to put together an economical solution that is also effective in long term operations,” said Wentzler.

The Value of Partnership

The Siemens 3VA and 3WA lines are critical components in the BESS project, delivering the functionality, flexibility and safety needed in a harsh environment. “I think the 3WA main and 3VA6 breakers have just been rock stars for us in the renewable space, which is very demanding on a breaker,” said Vermillion.

“Siemens can always be counted on for reliability, quality, and support,” said Sauls. Siemens understood the importance of shipping on time and the need for communication with EPEC along the way to ensure a smooth process. “What we’re looking for in a partner is someone that's interested in our business and is willing to go the extra mile for us. Siemens has done that from the beginning,” he said.

Building a Diverse Energy Mix

The local utility is addressing an important need in an area of the country where solar power is abundant. It serves as a cost-effective, energy-efficient and innovative example of how to address the country’s energy supply challenges.

“We don't have enough energy in this country,” said Vermillion. “We need natural gas, we need nuclear, and we need solar – and using large-scale battery sites is the next step. Having a diverse energy generation a beautiful thing, and this brings a lot of great value to Arizonans.”

Siemens | https://www.siemens.com/global/en.html

DEPCOM Power | https://www.depcompower.com/

Solar Landscape, the nation’s leading commercial rooftop solar developer, has announced a landmark $175 million long-term partnership with PGIM Private Capital, to finance its growing portfolio of projects that feed electricity directly into the distributed grid, initially across Maryland and Illinois.

PGIM Private Capital is the private capital arm of PGIM, the $1.4 trillion global investment management business of Prudential Financial, Inc. (NYSE: PRU).

The partnership – in the form of an institutional shelf debt facility – will finance the construction and operations of 74 Solar Landscape projects in Maryland and Illinois on 3 million square feet of commercial rooftops, creating nearly 43 megawatts (DC) of solar capacity for the surrounding communities.

“Commercial rooftop solar is America’s most shovel-ready energy source and this financing enables us to build more and build it faster,” said Solar Landscape Chief Financial Officer Clayton Avent. “This debt investment is another example of PGIM Private Capital’s long track record of strong investment into the energy sector. The first wave of these projects is already generating electricity to meet the country’s growing demand.”

The transaction marks an important step in Solar Landscape’s capital markets evolution and will enable dynamic and efficient deployment of debt capital into the company’s best-in-class rooftop community solar projects. The flexibility of the private shelf facility enables Solar Landscape to further expedite development and deployment cycles, generating energy into the distribution-level grid quickly and efficiently.

The shelf financing from PGIM Private Capital complements Walmart’s tax equity investment in the portfolio, which Walmart and Solar Landscape announced in October 2024. Subsequent shelf deployments across addressable markets are expected to follow in 2025 and beyond, further entrenching Solar Landscape’s status as the nation’s preeminent fully-integrated independent power producer focused on deploying solar and energy storage on commercial rooftops.

For PGIM Private Capital, the investment is part of its long-term approach to investment in clean energy.

“By building solar projects on existing commercial buildings, Solar Landscape is deploying energy quickly, efficiently and close to where it will be used, making it a sound investment in our energy future,” said Ingrida Soldatova, Senior Principal, Real Assets—Power at PGIM Private Capital. “We are always happy to continue adding to our portfolio of investments in the community solar space.”

More than a dozen of the projects in the initial investment portfolio were energized recently in Maryland and the balance of the portfolio is expected to come into service in 2025.

Solar Landscape | www.solarlandscape.com

UL Solutions Inc. (NYSE: ULS) announced the opening of its Europe Advanced Battery Testing Laboratory in Aachen, Germany, which will test batteries used in electric vehicles (EVs) and large-scale energy storage systems, significantly expanding the company’s battery technology testing capabilities and its European footprint.

Driven by the increasing demand for reliable battery testing services, the facility was purpose-built from the ground up to evaluate EV and industrial battery products during the research and development phases of battery manufacturing. The facility will also offer comprehensive evaluations of finished products to determine whether they meet safety and performance requirements, enabling original equipment manufacturers to access global markets.

“Our new location in Germany provides us with access to the region’s deep engineering talent and places us close to many of our key European customers,” said Jennifer Scanlon, president and CEO of UL Solutions. “We are meeting our customers where they are, helping the automotive and power sectors safely innovate in a world increasingly reliant on battery storage.”

The new laboratory replaces a smaller leased facility that was part of UL Solutions’ 2024 acquisition of battery testing and simulation company BatterieIngenieure. That acquisition significantly increased UL Solutions’ capacity for conducting tests, advanced simulations and in-depth failure analysis of battery technologies. A key strength of the new facility is its capability for estimating battery lifespans, a crucial factor for both manufacturers and consumers.

The opening of the UL Solutions Aachen laboratory arrives at a pivotal moment for the global energy transition and electrification. The International Energy Agency notes strong EV market growth, fueling a surge in battery demand, which jumped 35% in 2023 and is projected to increase tenfold. Battery storage is also expanding rapidly in the power sector, with deployments rising over 130% in 2023.

This facility is strategically located in North Rhine-Westphalia and is UL Solutions’ first in the EU solely focused on comprehensive battery testing services. It is home to dedicated battery science experts who conduct rigorous tests to determine cell, module and battery lifetimes, as well as evaluate safety and performance.

Specialized tests meticulously measure the ability to withstand a host of potential threats, hazards and adverse conditions, including misuse, off-gassing and thermal runaway, a chemical reaction that causes a battery to increase in temperature and pressure rapidly and can lead to fire and explosions. These tests help demonstrate that customers’ innovative technologies meet safety and performance standards established by UL Standards & Engagement, the International Electrotechnical Commission, the Society of Automotive Engineers, the United Nations and other globally recognized organizations.

The UL Solutions Europe Advanced Battery Laboratory adds to our global network of testing facilities focused on battery technologies. These include:

Learn more about UL Solutions’ battery testing services.

UL Solutions | https://www.ul.com/

Energy Storage May 15, 2025

Natural disasters including hurricanes, severe storms, winter storms, wildfires and heat waves are becoming more frequent and severe, causing widespread power outages across the United States. Between 2000 and 2023, 80 percent of U.S. power outages w....

Building codes and minimum building standards such as ASCE 7, Eurocode, and the National Building Code of Canada, are used to calculate the maximum forces a building may encounter. These forces result from wind, snow and seismic activity. For wind up....

The National Oceanic and Atmospheric Administration (NOAA) estimates that in 2024 alone, the United States experienced 27 weather- and climate-related billion-dollar disaster events, with losses totaling $182.7 billion. Severe convective storms — a....

As the world transitions to clean energy, one of the biggest challenges facing the solar industry isn’t technology or financing — It’s labor. The demand for skilled workers to install and maintain solar infrastructure far exceeds supply, threat....

At the first RE+ Microgrids event in New....

Ensuring the reliability and efficiency ....

Natural disasters including hurricanes, severe storms, winter storms, wildfires and heat waves are becoming more frequent and severe, causing widespread power outages across the United States. Between 2000 and 2023, 80 percent of U.S. power outages w....

The geospatial sector has long worked behind the scenes, enabling technological advancements. However, with the rise of artificial intelligence (AI) and digital twins, it is now playing a vital role in the modernization of energy grids. These innovat....

Businesses and communities have long relied on centralized power grids, but as energy demand increases and reliability becomes less certain, many are looking for alternatives. More companies are adopting microgrids and virtual power plants (VPPs), cr....

How can one know the climate impact of a purchase or investment? Clean energy production is about climate mitigation, but how can one know the climate impact of a purchase or investment? Many investors and buyers want to understand how t....

There is no question that weather events place enormous stress on the country’s power grids. Nowhere is this more clearly on display than in the renewable energy market, including the turbulent conditions of the offshore wind industry. As....

Hydrogen peroxide (H2O2) is well known as a household disinfectant, but in its concentrated forms, it has a powerful second life as a clean and efficient propellant used in space applications. When decomposed, H2O2 breaks down into oxygen and wa....