The Rise of Robo-Labor: How robotics are solving the labor crisis in solar energy

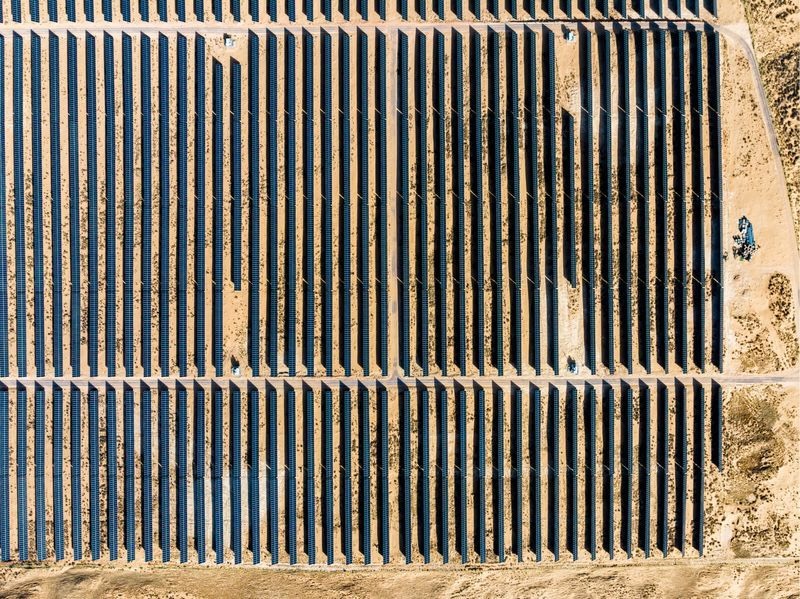

As the world transitions to clean energy, one of the biggest challenges facing the solar industry isn’t technology or financing — It’s labor. The demand for skilled workers to install and maintain solar infrastructure far exceeds supply, threatening to slow critical commercial and utility scale solar energy projects. With U.S. energy demand expected to increase by 50 percent by 2040, and 90 percent of new energy capacity coming from solar, we must find innovative solutions to scale solar installation. One promising answer lies in robotic technology, specifically Robo-Labor.

The growing need for solar and the labor crisis holding it back

Even though the demand for solar energy is skyrocketing, labor challenges in solar installation remain a major bottleneck. The industry needs skilled workers to meet installation goals, but the existing labor supply is simply not keeping up.

There are several factors that contribute to the labor crisis, starting with a lack of skilled and qualified workers with the necessary technical expertise to install solar panels efficiently and safely. Training programs have not scaled fast enough to meet demand, leaving many projects struggling to find experienced personnel. Additionally, prevailing wage requirements create financial constraints for developers, adding complexity to hiring and compensation structures. Another major issue is worker retention, as solar projects often experience labor turnover rates up to 50%, creating disruptions and inefficiencies.

The physically demanding nature of installation work, combined with competitive job markets, makes it difficult to maintain and retain a consistent workforce. As workers leave mid-project due to job fatigue or for other opportunities, developers face delays and increased labor costs from constantly hiring and training new employees.

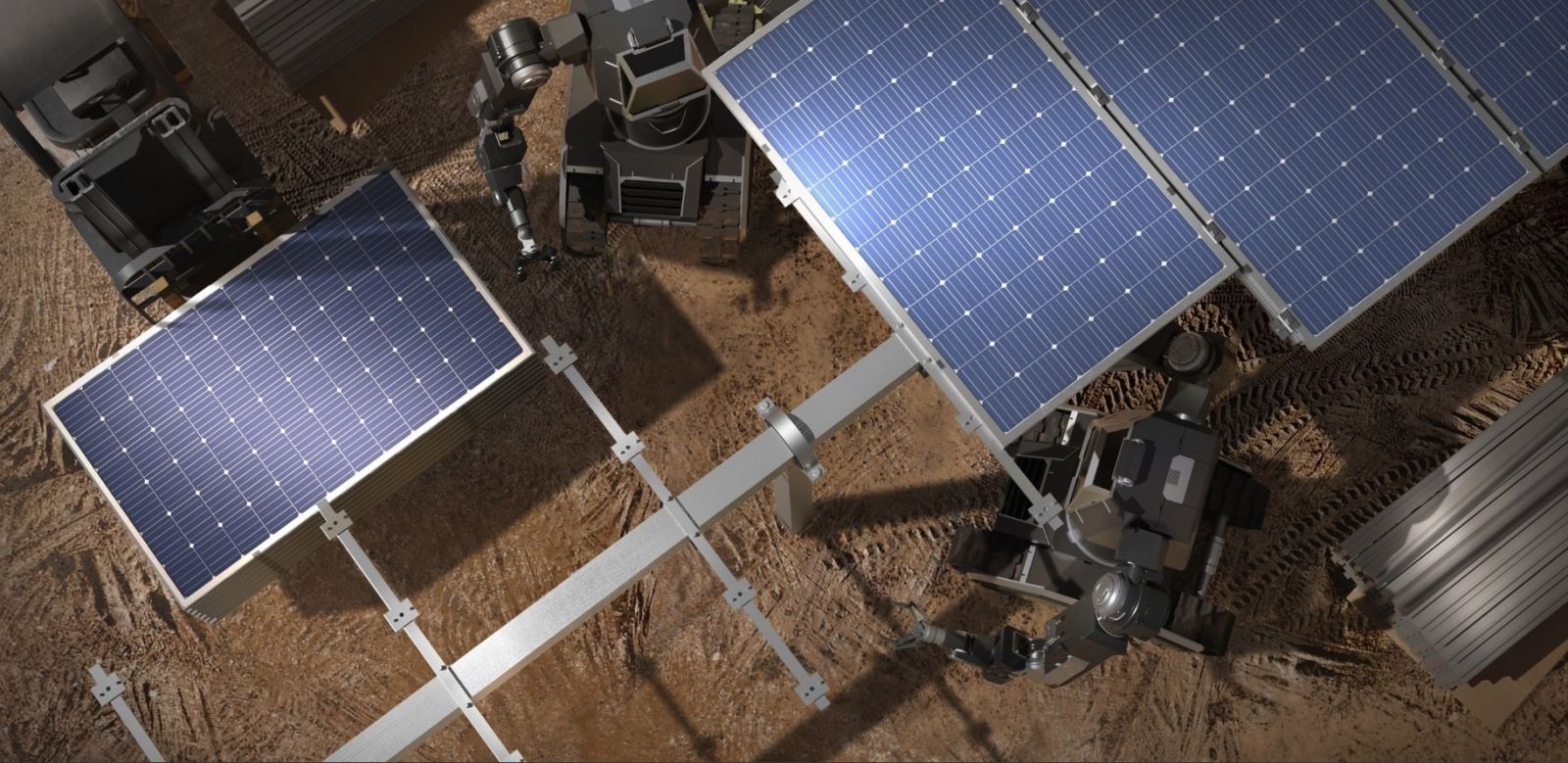

Robo-Labor is a new category of robotic technology designed to increase speed and efficiency, particularly in industries that require tedious, physically demanding tasks. Rather than replacing workers, Robo-Labor enhances productivity, improves safety, and accelerates project completion.

Robo-Labor refers to the integration of artificial intelligence (AI) with robotic systems to enhance automation in labor-intensive industries. Unlike traditional automation, which follows pre-programmed instructions, Robo-Labor utilizes machine learning, computer vision, and real-time data processing to adapt, optimize, and perform complex tasks with minimal to no human intervention. Essentially think of a fully autonomous fleet of robot workers that just simply get the job done with high levels of performance, efficiency, and quality. Robots can be designed and built to take on the most physically taxing and repetitive tasks, allowing human workers to focus on other tasks associated with overall solar project build and completion. This solution addresses labor shortages and improves overall safety while streamlining panel lifting, positioning, and securing components. By integrating robotics, developers can reduce project timelines and costs, making solar energy deployment faster and more efficient. Key features of Robo-Labor include:

1. Autonomous decision-making: AI algorithms enable robots to analyze environments, detect obstacles, and make real-time adjustments to get the job done as efficiently as possible without compromising quality.

2. Machine learning & adaptability: Robots are continuously improving by learning from digital simulations and real data, optimizing performance, and eliminating errors.

3. Computer vision & precision handling: Advanced sensors and imaging allow robots to recognize objects, align components, and handle intricate assembly tasks with high levels of accuracy and precision.

4. Collaborative operation: Robots can safely work alongside human workers, assisting in physically demanding or hazardous tasks.

5. Remote monitoring & predictive maintenance: AI-driven analytics can provide valuable insight to supervisors and management and predict maintenance needs without human intervention.

Boosting productivity and efficiency in extreme work environments

Beyond solving labor shortages, robotics also mitigate the risks associated with extreme work conditions. Many solar farms are built in rural and remote areas, some with high-temperature environments such as the desert and others with extremely cold environments like in northern Canada or northern Asia, where prolonged exposure can lead to injuries and long-term health risks for workers.

Robotic labor solutions excel in these conditions, operating without fatigue or health concerns that could compromise the quality of work. They perform in extreme temperatures, lift heavy materials, and complete repetitive tasks without risk of injury. Deploying robotics in these environments improves overall human worker safety while ensuring the robots adhere to the strictest safety and regulation measures. This advanced technology enables companies to optimize their existing workforce, freeing human laborers to focus on other tasks while robots handle the tedious, repetitive, and strenuous work.

For solar project owners and developers, this translates to significant savings. Faster installations mean quicker time-to-revenue, reduced financial risks, and improved return on investment. Reducing reliance on fluctuating labor availability also minimizes delays and ensures predictable project completion. This ultimately enables more clean energy supply faster and cheaper.

The future of solar installation

As the clean energy sector expands, innovation will be key to overcoming labor challenges and improving project execution. Robo-Labor is poised to become an essential tool in ensuring solar projects are completed on time, within budget, and without compromising worker safety.

The adoption of Robo-Labor addresses multiple challenges facing the commercial and utility scale solar industry. By tackling labor shortages, this technology ensures that solar projects can be completed at the scale and speed necessary to meet rising energy demands. By reducing worker exposure to physically demanding and hazardous conditions, it enhances worker safety and job satisfaction, which should lead to improved retention rates and reduced turnover. Additionally, by automating repetitive tasks, it increases overall efficiency, reducing project costs and making solar energy deployment more economically viable.

For the industry to fully leverage the benefits of Robo-Labor, industry stakeholders — including policymakers, developers, and technology providers — must work together to encourage adoption. As energy demand continues to rise, solar installation must keep pace. Robo-Labor represents a transformative approach to achieving this goal, making the industry more resilient, efficient, and prepared for the future. By embracing robotic labor solutions, we can accelerate the shift to clean energy and secure a sustainable future for generations to come.

Leo Ma is the founder and CEO of RoboForce and has devoted the last 15 years of his life to advancing the field of AI robotics. His founding mission behind RoboForce, “robotics for humanity,” is helping to address critical labor shortages while sparing humans from difficult, physically demanding, and unsafe work tasks and environments with cutting-edge Robo-Labor. Prior to RoboForce, Leo co-founded robotics company Cyngn and helped lead the company from startup to a successful IPO on the Nasdaq. He was also a software architect for self-driving cars at Baidu. He holds a master’s degree in computer science from Carnegie Mellon University.

RoboForce | www.roboforce.ai

Author: Leo Ma

Volume: 2025 July/August

.jpg?r=5021)