Small component, big impact: Bidirectional contactors and their role in advanced ESS design

As renewable energy adoption accelerates, energy storage systems (ESS) have quickly emerged as critical infrastructure for grid resilience. Solar panels and wind turbines generate more electricity than ever, but their intermittent nature means there's often a mismatch between production and demand. ESS bridge this gap by capturing surplus energy when it's abundant and releasing it during demand spikes.

As renewable energy adoption accelerates, energy storage systems (ESS) have quickly emerged as critical infrastructure for grid resilience. Solar panels and wind turbines generate more electricity than ever, but their intermittent nature means there's often a mismatch between production and demand. ESS bridge this gap by capturing surplus energy when it's abundant and releasing it during demand spikes.

Yet, behind the scenes, these systems are rapidly growing in complexity. Every internal component now faces higher demands for performance, reliability, and safety. One often overlooked yet essential device in this environment is the contactor.

Handling the current in both direction during the normal usage is the standard job of the contactor and the key requirement for ESS systems. Nevertheless, the critical event of an emergency switch off can happen in both charging and discharging mode. Delivering the same switch off performance, independent of current direction, is a key requirement that is fully supported by bidirectional solutions.

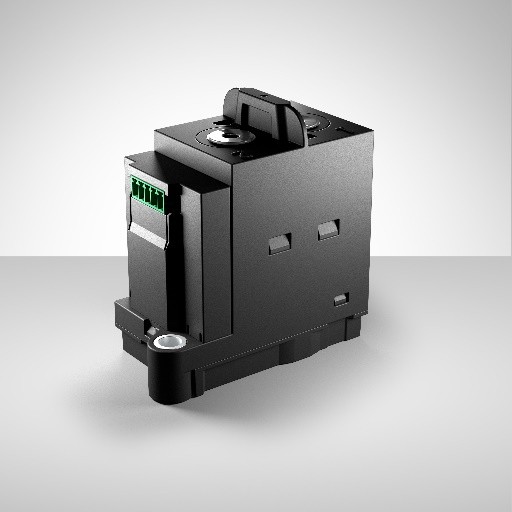

Bidirectional contactors like Eddicy’s C303, for example, manage substantial loads—up t o 1500 volts and 500 amps continuously. Crucially, they must also safely interrupt current during faults. High-current interruption generates arcs, which can damage equipment or create hazardous conditions. Modern contactors use advanced arc-resistant materials, such as silver-tin-oxide contacts. This material has a high melting point and is highly resistant against contact wear. It ensures stable conditions over the complete lifetime and helps to manage the thermal balance within the contact system.

o 1500 volts and 500 amps continuously. Crucially, they must also safely interrupt current during faults. High-current interruption generates arcs, which can damage equipment or create hazardous conditions. Modern contactors use advanced arc-resistant materials, such as silver-tin-oxide contacts. This material has a high melting point and is highly resistant against contact wear. It ensures stable conditions over the complete lifetime and helps to manage the thermal balance within the contact system.

Heat management is critical because high currents inevitably produce heat. Too much heat compromises performance and can lead to component failures. Having the right contact material, properly designed contact tips, and a coil drive to ensure the correct contact force is key to keeping the contact resistance low and heat buildup minimized. This directly translates into longer component life, fewer system maintenance intervals, and reduced TCO.

Space efficiency is another growing challenge. Energy storage installations, whether utility-scale or commercial, often require high energy densities within tight physical footprints. Manufacturers are responding by engineering contactors into more compact yet robust packages. Devices like the C303 illustrate this trend, maintaining high power-handling capacity within smaller, integrated formats.

Safety remains the fundamental priority. Contactors must reliably isolate high-voltage circuits when powered off and deliver minimal contact resistance during full-load operation. In system fault conditions, contactors need to rapidly isolate the affected circuit, safeguarding personnel and equipment. Bidirectional contactors with stable switching performance address these safety requirements head-on, improving overall ESS reliability.

Looking ahead, ESS are undergoing rapid transformations. Systems approaching 8 MWh containerized capacities and fully integrated AC block architectures are becoming common. These emerging architectures are reshaping electrical peak shaving and balancing strategies and placing higher demands on internal components, including contactors.

Contactors, therefore, must evolve to accommodate these advanced architectures. Continuous further development of mechanical contactors themselves, combined with the possible integration of intelligence, creates new possibilities to make systems safer and more reliable in the future.

While batteries and inverters often grab the headlines, contactors help drive the evolution toward smarter, more reliable ESS in the background. As energy storage scales to meet the needs of a renewable-powered future, components like bidirectional contactors will become increasingly critical—delivering greater performance, safety, and efficiency, all within smaller, smarter packages.

Eddicy – a Schaltbau Brand

www.schalbau.com

![]()