Safe Energy Storage is Critical for a Low-Carbon Energy Future

The installed base of energy storage is expected to increase 13 times by 2030. And Lithium-ion batteries, whether used for emergency power or to complement distributed energy resources or inside of vehicles, have a critical role in this growth. As the cost of these batteries has fallen over the last decade, the technology is increasingly found in uninterruptible power systems (UPSs), emergency power systems, and distributed energy installations around the world.

The installed base of energy storage is expected to increase 13 times by 2030. And Lithium-ion batteries, whether used for emergency power or to complement distributed energy resources or inside of vehicles, have a critical role in this growth. As the cost of these batteries has fallen over the last decade, the technology is increasingly found in uninterruptible power systems (UPSs), emergency power systems, and distributed energy installations around the world.

Battery technology continues to evolve, as do the codes and standards for its safe application new guidelines for testing are being introduced. Not only is it critical to stay informed of new standards and testing guidelines, it is also essential to recognize that the safety of energy storage doesn't start and end at the battery.

The skinny on storage safety codes

Several electrical industry organizations offer guidelines and best practices for the installation and testing of battery energy storage technology. The two most recent code developments for these systems include:

- NFPA 855: Standard for the Installation of Energy Storage Systems

and - UL 9540A: A test method for fire safety hazards associated with propagating thermal runaway within battery systems.

Although similar safety guidelines for energy storage systems have been in place for many years, the mandatory adoption of National Fire Protection Association (NFPA) and UL codes and testing guidelines depends on where the energy storage system is applied, as well as the version of the National Electrical Code (NEC) and International Fire Code (IFC) applied in the jurisdiction. This lack of consistency creates confusion. How can you be sure that your battery energy storage system is installed correctly and will operate safely for years to come?

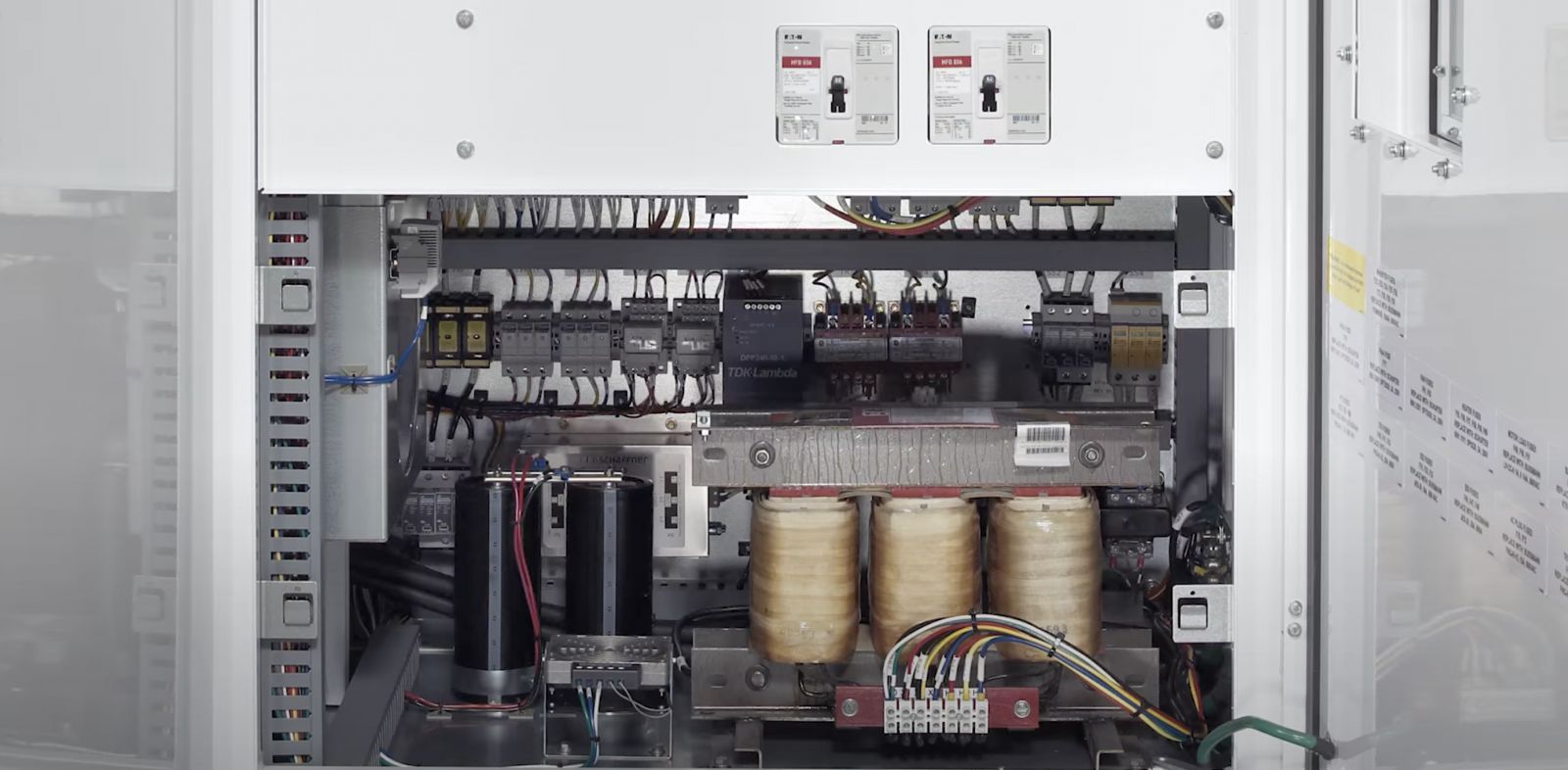

There is an entire ecosystem of working components that are part of energy storage systems, and each one has a role to play in enhancing the safety of the overall system. These components have long been required by NFPA codes and include unique certification criteria for circuit protection devices, inverters, battery management systems and more. The testing methodology outlined by UL 9540A should be considered in line with the NFPA 855 guidelines to ensure the long-term safety of battery energy storage systems.

Testing guidelines for energy storage systems

While codes and standards vary by region, it is important to understand the testing process UL recommends for safe energy storage installation and operation. A thorough understanding of this process will help you provide your local authorities, insurance providers and fire mitigation professionals with the information they need to quickly assess the safety of your installed battery energy storage system.

The UL 9540A test method was developed to evaluate the potential for thermal runaway fire propagation, should it occur during the life of the system. It addresses key issues identified by building codes and the fire service, including:

- Proper Battery Energy Storage System (BESS) installation

- Compliance with installation ventilation requirements

- Effectiveness of fire protection (integral or external)

- Applied fire service strategy and tactics

Here's a high level look into the how the testing process works:

- Cell level test: Whether the battery cell itself can exhibit thermal runaway, and if the connected battery management system (BMS) can take appropriate action to mitigate the problem

- Module level test: Determining the propensity for propagation of thermal runaway and effectiveness of BMS control systems

- Unit level test: Evaluation of fire spread should a thermal event occur

- Installation level test: Effectiveness of physical fire protection systems

Layers of protection support safe energy storage systems

Layers of protection support safe energy storage systems

Batteries are one part of energy storage systems. There are a host of other components that have applicable codes designed to enhance the safety of the overall system. For example:

- UL 489 circuit breakers provide overload (thermal) and short-circuit (magnetic) protection to a circuit and its downstream components like batteries.

- UL 489B molded-case circuit breakers, molded-case switches and circuit breaker enclosures are certified for use with photovoltaic (PV) systems and DC applications.

- UL 1741 storage inverters are certified to remain online and automatically adapt power output in real-time to stabilize the electric grid during periods of abnormal operation such as heat waves or brownouts.

- UL 1998 and UL 1973 certified battery management systems provide confidence that the battery and related management systems support safety functions in the case of a failure.

Before designing or installing an energy storage system, know the code requirements beyond the physical battery system that help keep people and property safe. As with any electrical product, it is important to source this equipment from trusted suppliers who can provide evidence of third-party testing when possible.

Safe energy storage is critical to support the energy transition

Energy storage is growing and has vast potential to transform how we produce and consume electrical energy. To support the growth of this transformative technology, it is essential that proper precautions be put into place to advance safety.

Understanding the codes and standards related to energy storage is a start, but many requirements vary by region. Use the latest NFPA guidelines as a baseline when designing and installing battery energy storage systems, and find confidence in the thorough testing and reporting processes outlined by UL 9540A. Most importantly, consult early and directly with local Authorities Having Jurisdiction (AHJ) during the conceptual or design stage of the energy storage system environment. If waivers or exceptions to the codes are applicable, the AHJ may have the final say. Direct consultation will provide the confidence upfront that the planned installation will be accepted and approved.

Battery safety is a critical factor to the technology's widespread adoption in the energy marketplace. A commitment to safety when it comes to the installation and operation of these systems will enable the energy transition with a more dynamic ecosystem capable of providing much more sustainable electricity than ever before.

Ed Spears is Product Marketing Manager, Critical Power Solutions, Eaton. Eaton is dedicated to improving people's lives and the environment with power management technologies that are more reliable, efficient, safe and sustainable.

Eaton | www.eaton.com

Author: Ed Spears