Iridium Scarcity Challenges Clean Hydrogen Scale-Up

Hydrogen is a carbon-free fuel that will play a vital role in shaping the global clean energy landscape. In anticipation of the growing demand for hydrogen, technology manufacturers are reinforcing supply chains and preparing for a rapid scale-up.

As the demand for clean hydrogen surges, so does the necessity for electrolyzers. Electrolyzers can produce clean hydrogen with renewable electricity and water inputs. Among the various types of electrolyzers available, proton exchange membrane (PEM) electrolyzers are particularly well suited for clean energy applications due to their compatibility with variable renewable electricity resources such as wind and solar power. Consequently, a significant portion of the anticipated surge in installed capacity will be dedicated to PEM electrolyzers.

However, the growth of this industry will encounter a potential hurdle due to its reliance on precious catalyst materials such as iridium. Currently, the operation of PEM electrolyzers in the market hinges on using iridium catalysts. As the electrolyzer industry continues to expand, the limited availability of iridium globally will emerge as a significant obstacle for scaling up production. In its 2021 Global Hydrogen Review, the International Energy Agency warn that, if PEM electrolyzers exclusively cater to the demand in their Net-Zero Emissions Scenario, by 2030, the need for iridium would surge to 63 kilotonnes, a staggering nine times the current global production. Clearly, the global scarcity of iridium poses a major threat to the expansion of PEM electrolyzer manufacturing to meet clean hydrogen demand.

Drawbacks of iridium

All currently available commercial PEM electrolyzers rely on iridium catalysts. Within the electrolyzer, iridium catalyzes the oxygen evolution reaction, reducing the electricity needed to produce a given amount of hydrogen. Conventional electrolyzers use iridium catalysts because of the material's excellent activity and stability under the harsh conditions of PEM water electrolysis. However, there are several drawbacks associated with using iridium in these systems:

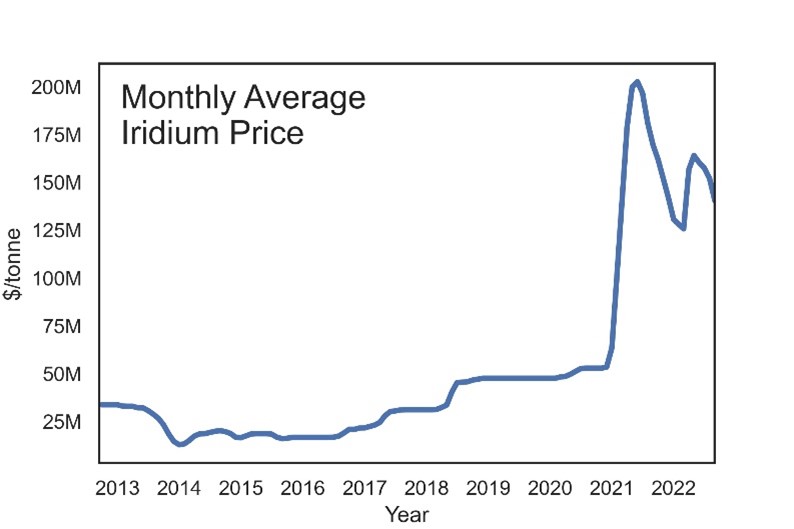

(Data from Johnson Matthey shoe high volatility ovet the past decade)

Cost: Iridium is one of Earth's rarest and most valuable elements. Its rarity and high cost present constraints on its extensive adoption in industrial-scale hydrogen electrolyzers, hindering large-scale deployment.

As hydrogen develops as an alternative energy source, the economic impracticality of iridium for widespread use becomes apparent.

Competing industries: Compounding the issue, the demand for iridium extends beyond clean energy applications, reaching into electronics, communications, military, and transportation industries. This growing demand, coupled with supply chain delays, drives significant price volatility, creating additional obstacles for its integration into clean energy technologies.

Sustainability and environmental impact: Mining and refining iridium have harmful environmental implications. The extraction and processing of iridium negatively affects ecosystems and contributes to carbon emissions. As the demand for hydrogen electrolysis grows, it is essential to consider the overall sustainability and environmental impact of using iridium in these systems.

Potential solutions

Recycling is one way to lessen the impact of iridium scarcity. Since the catalyst used in electrolysis is not depleted, once the electrolyzer reaches the end of its lifespan, the iridium can be recovered and reused in future applications. While current iridium recycling rates are relatively low, researchers are optimistic that the end-of-life recycling rate could significantly increase, potentially reaching up to 90 percent.1 This enhanced recycling approach could address the iridium constraint issue in the long run, when more electrolyzer capacity becomes available for material recovery post-usage.

In the short term, however, existing electrolyzer capacities are too low for recycled end-of-life materials to meaningfully contribute to iridium supply for the growing industry. An approach that could solve the iridium problem in the near term is to minimize or completely eliminate the use of iridium in electrolyzers. Researchers and engineers are actively exploring alternative catalyst materials to replace iridium in conventional PEM electrolyzers. The goal is to find catalysts with a similar performance to iridium, but at a lower cost and higher abundance to enable the widespread adoption of water electrolysis technology.

Revolutionary catalyst

In discovering alternative materials, researchers must balance three often competing goals: reducing material costs, increasing stability, and enhancing activity. The combinatorial space of potential catalyst compositions is vast, so rapid and targeted exploration is necessary.

To this point, exciting breakthroughs in catalyst research have emerged from the California Institute of Technology (Caltech), bolstered by a $122 million investment by the U.S. Department of Energy. The program's endeavors have yielded over 30 patents and the development of the Catalyst Discovery Engine (CDE). The CDE can make and test readily available catalyst materials 10,000 times faster than any other method. This speed breakthrough allows the user to rapidly comb the materials space for alternative materials to replace iridium.

Looking ahead

The significance of this breakthrough cannot be overstated. The planet possesses only about one-tenth of the required iridium to satisfy the rapidly escalating global demand for hydrogen electrolyzers. The discovery of new catalysts offers a promising pathway toward realizing a hydrogen economy that relies on abundant and sustainable resources. With ongoing advancements fueled by collaborative efforts, we march closer to a future powered by clean and efficient energy sources.

The evolution of clean hydrogen production hinges on the ability to address the challenges posed by the scarcity of catalyst materials. By investing in research, innovation, and sustainable practices, the industry can strive towards developing efficient, cost-effective, and scalable solutions that meet the growing demand for electrolyzers, and propel the widespread adoption of clean hydrogen as a viable energy source.

Mark McGough is the President and CEO of H2U Technologies. He is an internationally recognized expert for building high-growth energy technology businesses and delivering attractive investor exits. Prior to H2U Technologies, McGough was the President of Maxwell's ultracapacitor business acquired by Tesla, CEO of Pentadyne, Ioxus and Hartland Controls.

Mark McGough is the President and CEO of H2U Technologies. He is an internationally recognized expert for building high-growth energy technology businesses and delivering attractive investor exits. Prior to H2U Technologies, McGough was the President of Maxwell's ultracapacitor business acquired by Tesla, CEO of Pentadyne, Ioxus and Hartland Controls.

H2U Technologies | www.h2utechnologies.com

1 Minke, Christine, et al. International Journal of Hydrogen Energy 46.46 [2021]: 23581-23590

Author: Mark McGough

Volume: 2023 September/October