How to Properly Protect a BESS Power Circuit from Overcurrents

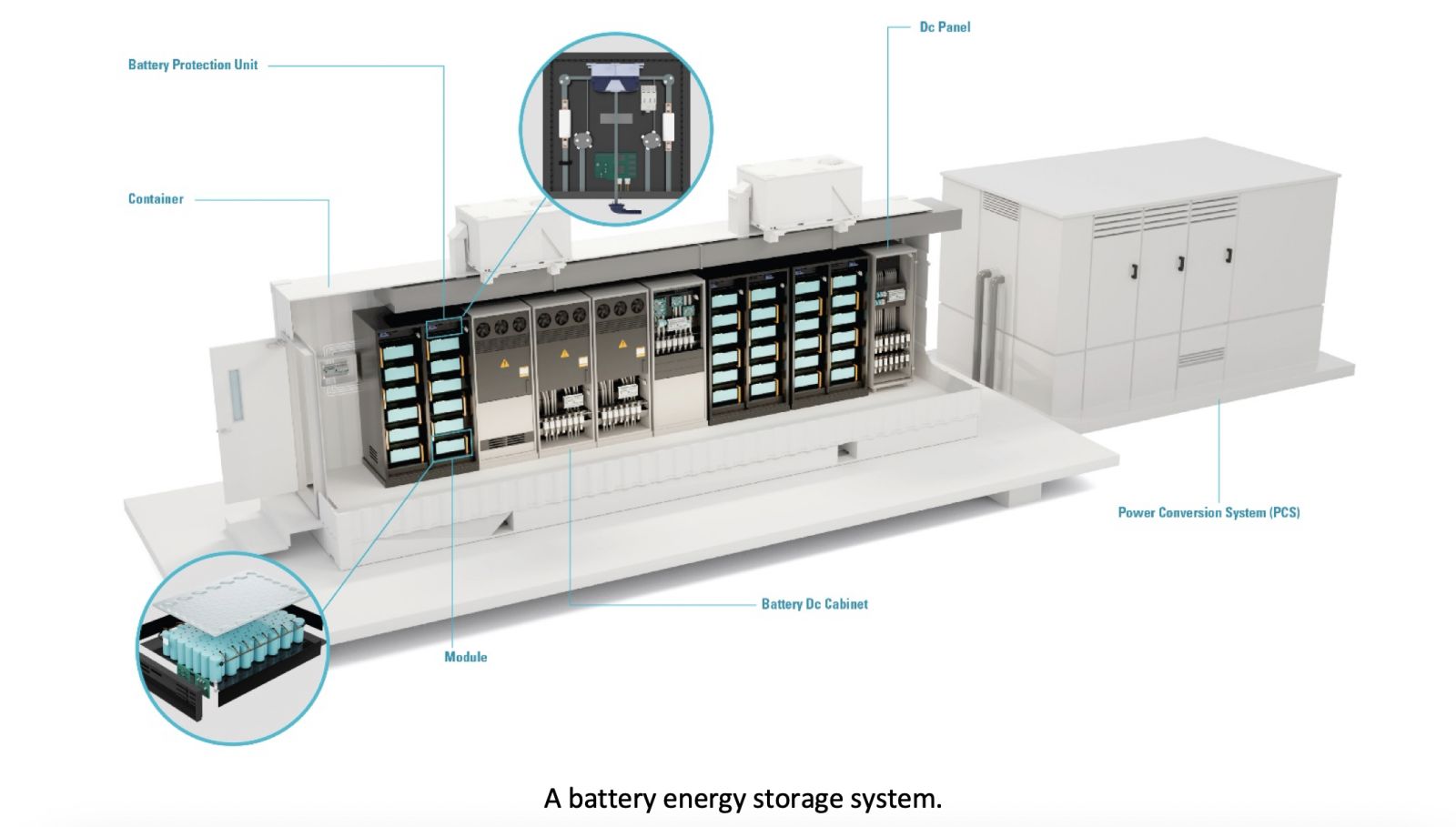

A battery energy storage system (BESS) is a combination of smaller units of energy (cells, modules, racks) to attain the energy requirement for a particular system. Protection is necessary when energy and voltages combine from the modules, as well as from the battery racks.

Fuses are an efficient and effective way to protect a BESS from overcurrents. Overcurrents not only frequently damage systems, but are also the culprit of downtime, which hurts a company’s bottom line.

The advantages fuses bring to a BESS are immense. Without a need for complex wiring or additional components, fuses are a great way to protect a system simply and cost-effectively. Fuses can also be easily replaced without the accumulation of additional downtime.

The low watt loss of BESS fuses prevents energy loss, which efficiently minimizes wasted power from components. Their compact size makes designing high-energy density systems possible. The dc-breaking capacity (up to 250 kA at 1500 V dc) enables the design of a long-duration BESS, while the low minimum breaking capacity of the fuses offers protection for lower fault-current levels. All in all, fuses are a win for a BESS.

Circuit protection must be adequately sized to prevent catastrophic failure. The optimal circuit protection component to use depends on the following:

- system voltage

- system nominal current

- time constant

- withstand rating of the interconnecting components

- ambient conditions

- location of the component within the system

Where circuit protection is important

According to UL 1741 32.4 (third edition), units that are intended for connection to a battery circuit should be provided with overcurrent protection. Circuit protection is important at the level of the module, the battery rack, the dc panel (also known as the dc-array combiner cabinet), and the inputs to the power conversion system (also known as an inverter).

There are two circuits within a battery system: the power circuit (also known as the main circuit), and the control circuit (also known as the secondary circuit). The control circuit monitors and collects data, provides information about the system’s operation, and sends trip signals when necessary. The power circuit carries the electricity that operates the load.

A BESS requires many different types of circuit-protection, including:

A BESS requires many different types of circuit-protection, including:

- Fuses

- Arc-flash relays

- Ground-fault relays

- Surge protective devices

Our focus here is on fuse protection for the power circuit in a BESS.

Fuse protection for the power circuit

The cell is the smallest component within an energy storage system. A module is made up of cells that are combined in parallel and series configurations. The modules are stacked in series to form a rack, which generally has the same voltage as the system.

A rack is comprised of modules that are stacked in series together. When each of the module’s voltages are added together, they form the battery rack’s voltage.

To calculate the system’s required voltage, add the battery-rack modules’ voltages together. The battery rack’s voltage is equal to the dc system’s voltage. For example, with a 1500-volt system, each rack will be 1500 V dc. If the module voltage is 50 V dc, then the rack will need to contain 30 modules in series.

A BESS’s total energy is made up of the battery racks’ energy combined in parallel.

The module must be protected from short circuits within the modules or the battery rack. Overloads that occur within a BESS are usually managed within the battery management system (BMS), so most circuit protection is mainly for short-circuit protection, not overloads.

The next area to protect involves the battery rack. This circuit protection is usually at the battery protection unit (BPU), found at the top of the battery rack, and consisting of the aggregated energy from each of the modules. The circuit protection at this level is usually rated at a higher system voltage than the voltage in each module.

At the level of the battery rack, you need fuses that will protect against short-circuit currents and h ave a low minimum breaking capacity to protect the contactors.

ave a low minimum breaking capacity to protect the contactors.

Circuit protection (fuses) isolates the battery rack in the event of a fault. To get to the required amount of energy, many racks combine in parallel into the dc panel. The dc panel uses fuses to protect every rack from short-circuit faults.

In applications where the rack voltage is 1500 V, the module fuse must be at least 1500 V dc. Never use a fuse that is not rated to the system voltage.

UL 1973 7.9.10 says:

“Fuses provided for battery overcurrent protection including short circuit protection shall be evaluated for both short circuit and overload conditions. Fuses that are evaluated for short circuit conditions only (type aR fuses), shall be provided with supplementary protection (e.g., the BMS) to ensure protection under overcurrent conditions in ranges below those covered by these types of fuses.”

Additionally, UL 1973 7.9.11 says:

“Protective components of battery modules intended for series connection in battery systems shall be rated for the maximum voltage of the intended battery system.”

In general, fuses within a BESS should be designed to meet IEC 60269-7, Supplementary requirements for fuse-links for the protection of batteries and battery systems.

To protect the inputs of the power-conversion devices that are connected to the BESS, use fuses that will isolate the BESS from the power-conversion system in the event of a fault. A BESS is a worthwhile investment. Make sure to have a thorough understanding of the system’s operation and subunits that contribute to its overall energy.

Immanuel Umenei is the senior global segment manager for renewable energy at Littelfuse. He has over a decade of low-voltage system design, applications engineering, and business development experience in specifying overcurrent circuit protection components for different low-voltage electrical systems, including renewable energy technologies such as solar/photovoltaic and battery energy storage. Immanuel has a master’s degree in engineering from the University of Illinois, Chicago.

Immanuel Umenei is the senior global segment manager for renewable energy at Littelfuse. He has over a decade of low-voltage system design, applications engineering, and business development experience in specifying overcurrent circuit protection components for different low-voltage electrical systems, including renewable energy technologies such as solar/photovoltaic and battery energy storage. Immanuel has a master’s degree in engineering from the University of Illinois, Chicago.

Littlefuse | www.littelfuse.com

Author: Immanuel Umenei

Volume: 2023 July/August