Harnessing the Potential of Repurposed EV Batteries for Safe and Sustainable Energy Storage

As North America accelerates its transition toward a cleaner and more resilient energy future, battery energy storage systems have emerged as critical infrastructure components. From stabilizing grid-scale renewable energy integration to providing commercial energy independence, these systems are foundational to our sustainable energy landscape. Within this evolving sector, the repurposing of electric vehicle (EV) batteries presents a particularly promising approach that addresses both safety and sustainability concerns simultaneously.

Closing the supply gap

The demand for reliable, scalable battery storage is skyrocketing yet supply struggles to keep pace. Repurposed EV batteries offer a practical, impactful solution to bridge this gap. By giving these batteries a second life, we not only extend their usefulness but also reduce the environmental footprint associated with raw material extraction and manufacturing.

The intertwined importance of safety and sustainability

Safety and sustainability in battery technology are interconnected priorities, not isolated goals. Safety is essential for building consumer confidence and driving adoption. Battery failure incidents can erode public trust and slow the transition to cleaner energy alternatives. Simultaneously, the environmental and social impacts of battery lifecycles — from mineral extraction to end-of-life management — necessitate the adoption of sustainable practices throughout the industry.

An important connection emerges when repurposing EV batteries for stationary storage applications. This sustainability measure inherently enhances safety due to the batteries' proven operational history. Having typically performed in demanding EV applications, these batteries have already survived the initial "infant mortality" period, which typically lasts 1-2 years, during which manufacturing defects are the primary cause of premature cell failures. Consequently, repurposed batteries that have successfully endured this phase offer greater reliability against early, defect-driven failure modes, contributing to the overall system.

Additionally, EV batteries are engineered to exceptionally high safety standards, designed to protect vehicle occupants under demanding conditions. Repurposing leverages these inherent safety features for second-life applications in stationary storage environments. When deployed in these applications, the batteries typically operate at significantly lower current ratings (C-rates) compared to their mobile specifications, reducing stress on the cells and further enhancing operational safety and longevity.

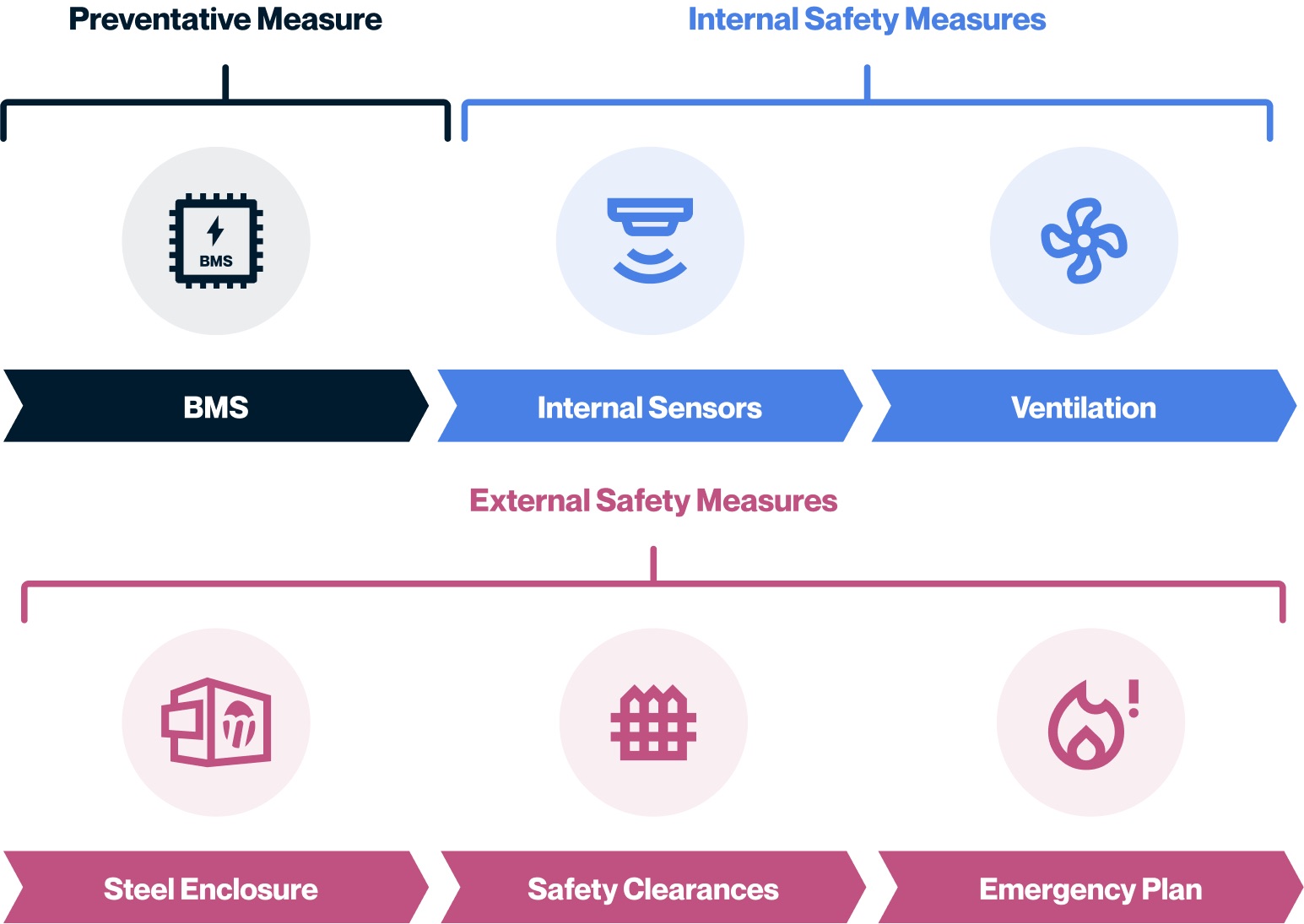

Best-practice safety layers for BESS

Decades of incident data show that the fastest way to maintain battery health is to leverage software for proactive intervention. An optimized Battery Management System (BMS) vigilantly monitors each cell, responding to voltage, current, or temperature anomalies within milliseconds. This rapid response ensures immediate action, mitigating the risk of escalation.

Recognizing that no single safeguard is foolproof, leading projects incorporate additional layers of protection. Smoke, heat, and hydrogen sensors are strategically placed inside enclosures, acting as secondary monitors to detect off-gassing and hot spots, both of which are indicators that a battery safety incident may have happened.

To manage these indicators effectively, regulatory bodies increasingly advocate for advanced ventilation systems. These systems, triggered automatically by detectors, improve visibility for responders and prevent secondary ignitions.

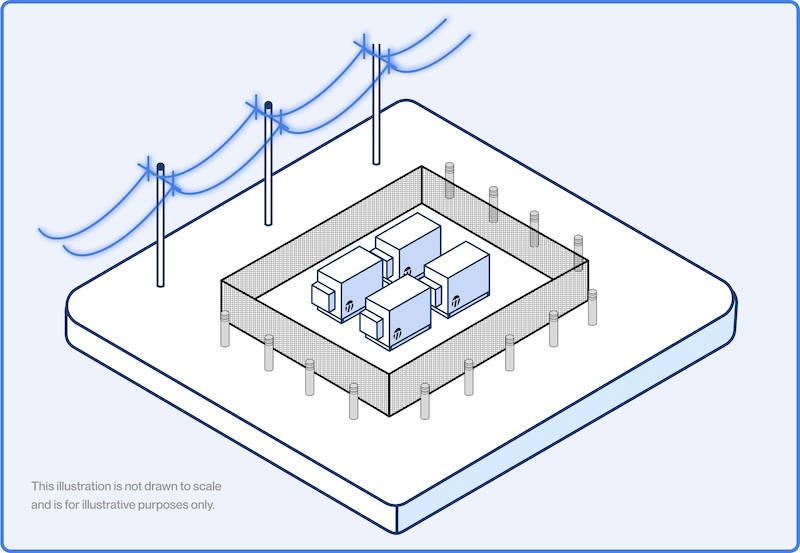

Effective hardware design further enhances safety. Guidelines emphasize the importance of non-combustible standoff zones, vehicle-rated bollards, and readily accessible Emergency Responder Guides detailing shut-off procedures and step-by-step isolation sequences.

This multi-faceted approach creates a robust safety net, ensuring that battery energy storage systems operate reliably and securely, protecting both infrastructure and communities.

Emerging innovations

The field is rapidly evolving, with several innovative approaches enhancing the safety and sustainability of repurposed batteries in stationary storage applications:

AI integration

AI-driven battery management systems are revolutionizing predictive maintenance, safety monitoring, and cell balancing capabilities. These intelligent systems can identify potential issues before they become critical, extending battery lifespan and enhancing operational safety.

Thermal management innovations

Effective thermal management is crucial for maintaining optimal battery performance and preventing potential safety issues. Innovative cooling strategies and controlled ventilation systems are significantly enhancing the safety and efficiency of repurposed battery installations. These technologies ensure consistent temperatures, which extend battery lifespan and minimize the risk of overheating.

The critical role of regulation and standardization in safety standards

Clear, harmonized regulations and standards remain crucial for driving both safety and sustainable practices in battery energy storage. Safety frameworks developed by standards, such as UL 1974, UL 9540, and codes such as NFPA 855, provide essential guidelines for the design and installation of battery energy storage systems.

Industry-wide adoption of standardized approaches to battery assessment, testing, and transportation will be crucial for BESS built with repurposed EV batteries to perform optimally in stationary energy storage. As the industry matures, continued convergence around best practices will be essential to realizing the full potential of these EV batteries.

Gabriel Soares is the co-founder and CTO of Moment Energy, responsible for leading research and technology development. He oversees the design, building, and testing of Moment Energy’s battery energy storage systems and its proprietary battery management system. Highlighting Moment Energy's commitment to advancing industry safety standards, Gabriel represents the company on several key technical committees, including NFPA 855, CSA C800, UL 9540/9540A, and UL 1974. Before founding Moment Energy, Gabriel gained extensive experience at top engineering companies like Intel, focusing on SSD testing automation and simulations, and Tesla’s thermal system development team. In 2023, he was awarded the Forbes Top 30 Under 30 award.

Moment Energy | www.momentenergy.com

Author: Gabriel Soares

Volume: 2025 July/August