Greenlighting the Job: An overview on permitting requirements for energy storage projects

Early understanding of permitting requirements for an energy storage project prior to the start of construction is critical, not only for the success of the commercial enterprise, but also the assurance of technical requirements, and the safety of the local community. It’s so important, in fact, that the permitting process has been known to make or break commercial operation dates.

Officials in local counties, cities, and states (authorities having jurisdiction or AHJ) have very limited knowledge of the permitting requirements imposed on developers when it comes to energy storage. As the local AHJ grants these project permits, it is in the interests of both the developers and the community that the AHJ gain some in-depth knowledge of the operation to help guide the project before construction begins.

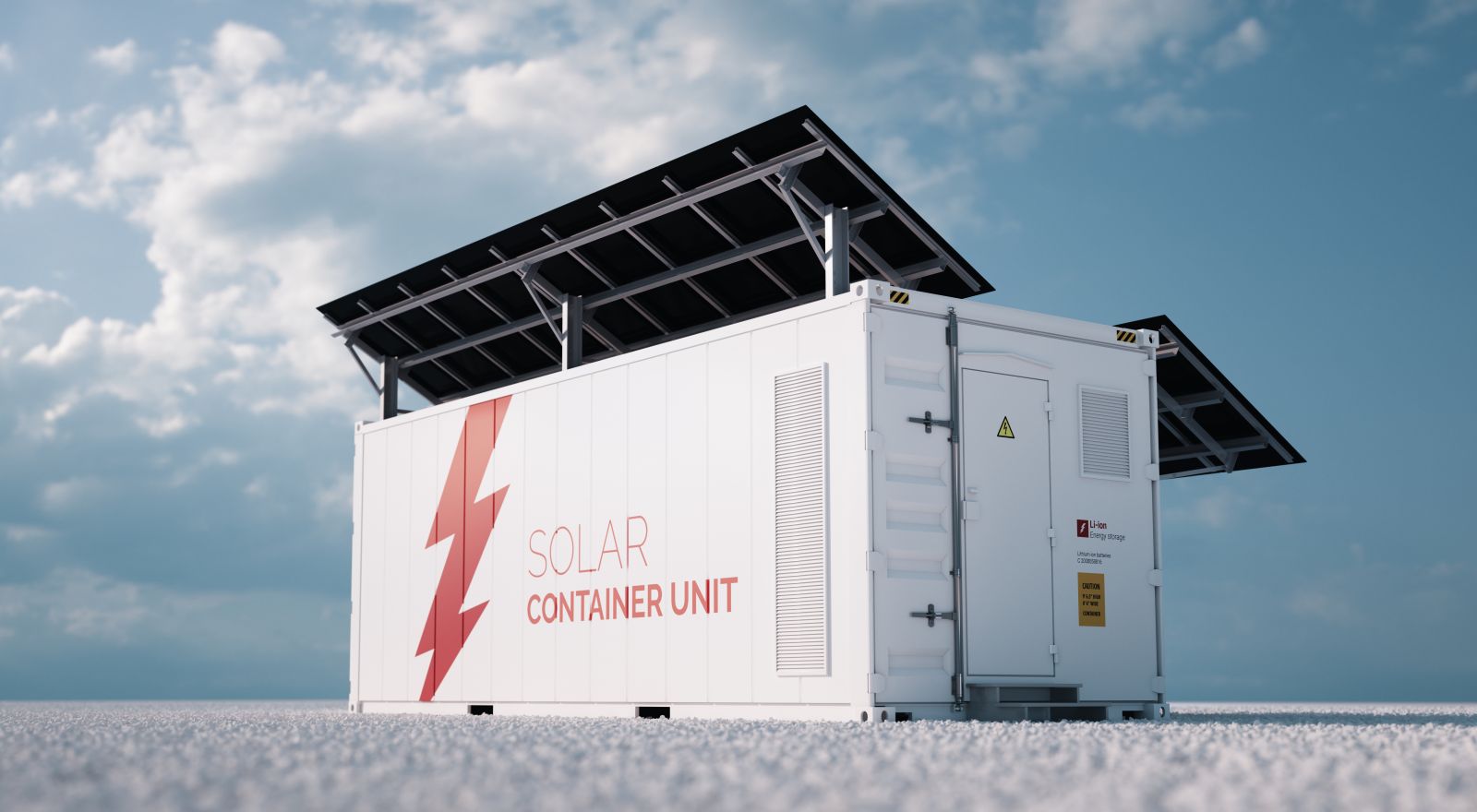

A lithium–ion battery stored in a 20-to-40-foot container contains a massive amount of potential energy. The benefit of battery storage/stored potential energy in a small footprint is that it can enhance grid reliability and excess-renewables-charge that, otherwise, would be clipped (not reach its maximum high or low point). When considering permitting for an energy storage project, AHJ should understand capacity verification, energy storage project checks/setbacks, and key considerations for the local community.

Capacity verification

A use case with conditions similar to those of the proposed alternative energy project site can help describe how project developers will perform tasks to verify the new site’s energy capacity. The use case can adapt over time prior to the signing of the offtake or purchase agreement.

These use cases directly drive the cycle count (how often the battery completes a full charge and discharge). The cycle count determines the acreage needed to build the project, as well as the space reserved for future augmentation over the terms of the offtake agreement. These initial overbuild proposals, augmentation plans, and conceptual layouts go a long way — at a fairly minimal cost — to derive a probability of 50 percent (P50) or P80 view of verifying the capacity.

Developers benefits from this exercise, even prior to submitting an interconnection application that will often lock into a mega-watt alternating current (MWac) size requirement. For example, if an interconnection study is for 100MWac, and it is in a four-hour market, the economics would indicate that an 80 MWac project at four hours is not lucrative because the interconnection utility is upgrading the site for 100 MWac. The optimization of MWac and duration, based on the ISO available revenues, must be balanced.

The second part of this exercise is budgeting the correct amount of environmental surveying that is beyond the desktop evaluation. Typically, desktop, wetland, or flood data is used, but, from a buildable-area standpoint, this information can be outdated or extensive. The buildable-area of a stand-alone storage project can be drastically impacted if it is located adjacent to a substation, and the environmental diligence shows more extensive exclusions than the initial desktop analysis.

Project progress checks or setbacks

Currently, lithium-ion is the most common chemistry for utility-scale, commercial, and industrial energy storage projects. Tier 1 suppliers of these products have undergone UL9540A* testing prior to site delivery to evaluate the effects of thermal runaway**. This UL standard does not have a strict pass/fail criteria, but is more focused on a report’s conclusions on how a given cell behaved. A single-cell test for UL9540A certification does not guarantee that the battery containers on a given project will never experience thermal runaway.

A separate discussion should address operational stewardship, to ensure how the battery is being charged/discharged within the bounds of the manufacturer’s requirements. Incorporating proper progress checks or setbacks during the permitting phase is critical for operational needs, personnel safety, and local community protection. As part of the capacity verification, conservative setbacks based on NFPA 855*** guidelines and container separation standards need to be put in place; this enhances overall system safety and mitigates system risks. If these setbacks are not put in place during the hearing process for permitting, a 100 MWac by four-hour project could be shrunk to an 80MWac by four-hour project, with zero room for augmentation reserve.

Fire department and local AHJ engagement

It’s vital that you engage the local AHJ and/or fire department early in the project’s life-cycle. During the planning process, representatives of each of these groups are often present (with supporting or dissenting voices) when a developer applies for a permit.

Many U.S. regions that use battery storage have created specific requirements pertaining to setbacks, zoning, and application checklists that must be completed prior to issuing a developer’s permitting request. For instance, because it services such a dense metro area, the New York City Fire Department most likely has the most stringent safety requirements regarding an approved battery supplier list and qualification process.

Surprisingly, there are massive deployments of battery storage in many areas where management teams have never seen, reviewed, or even understood the technology. In these circumstances, the typical response is fear of the unknown.

Often, during a thermal runaway event, a less-informed local fire department official’s response might be to “let it burn”. The official’s reasoning most likely is that an intervention (1) will not put out the fire, and (2) the loss of life will never be worth the risk of losing a battery storage asset.

Public news around battery fires from utility-scale projects or electric vehicles can dampen the positive response to an energy storage project during permitting discussions. Providing the proper technical battery storage facts to the local fire department and AHJ can help them understand all that is involved. It also sends the message that developers are designing the project with public safety in mind.

Though details of safety testing have not yet been officially defined by the industry, it is in the best interests of the energy storage installation and its developers, investors, and/or management to develop a site-specific safety and emergency response plan in collaboration with the local fire department, and to have the installation O&M teams review it regularly.

With new and larger installations being built year over year, storage project permitting requirements are “where the rubber meets the road”. They verify operational capabilities, assure adequate planning has been developed, and support community safety. There is no downside for AHJ and the local community to become educated on energy storage system safety features, and how they eliminate or reduce risk. This knowledge can only add to the local success of the operation.

* UL 9540A is the Standard for Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems, to help manufacturers have a means of proving compliance with the new regulations.

** Thermal runaway, as defined by the National Fire Protection Association (NFPA) in NFPA 855, is when a battery cell increases in temperature at a faster rate than it can dissipate heat and begins to self-heat, causing an uncontrollable increase in temperature which can, but doesn’t always, lead to off-gassing, fire, and/or explosion.

*** NFPA 855 is the National Fire Protection Association Standard for the Installation of Stationary Energy Storage Systems.

Matthew Towery, PE, PMP, is a Senior Manager of Energy Storage at Enertis Applus+, a global consulting and engineering firm for renewable energy projects and storage solutions.

Enertis Applus+ | www.enertisapplus.com

Author: Matthew Towery, PE, PMP

Volume: 2023 July/August