Out of Sight: Submarine cables are crucial for off-shore wind growth

Globally, offshore wind farms are an increasingly popular source of cost-effective and dependable renewable energy. The United States has begun to harvest the strong winds off its coasts to build out this industry; from a modest 30 MW currently in operation, East Coast states have issued policies targeting 25 GW within the next decade. By summer 2021, 9.7 GW will have been awarded in the Northeast (New York, New Jersey, Massachusetts, Connecticut, and Rhode Island). For the Mid-Atlantic and Southeast, developers have already outlined nearly 6.8 GW in incremental opportunities across North Carolina, Virginia, and Maryland. This growth and market opportunity will create a robust U.S. supply chain to supply and install the components necessary for an offshore wind farm.

As majestic white turbines begin adorning coastal landscapes beyond the horizon, key components to the game-changing potential of offshore wind energy lie unseen, beneath the waterline. These are the high voltage submarine cables that will export the sustainably generated energy to the electric power grids onshore - sometimes hundreds of miles away.

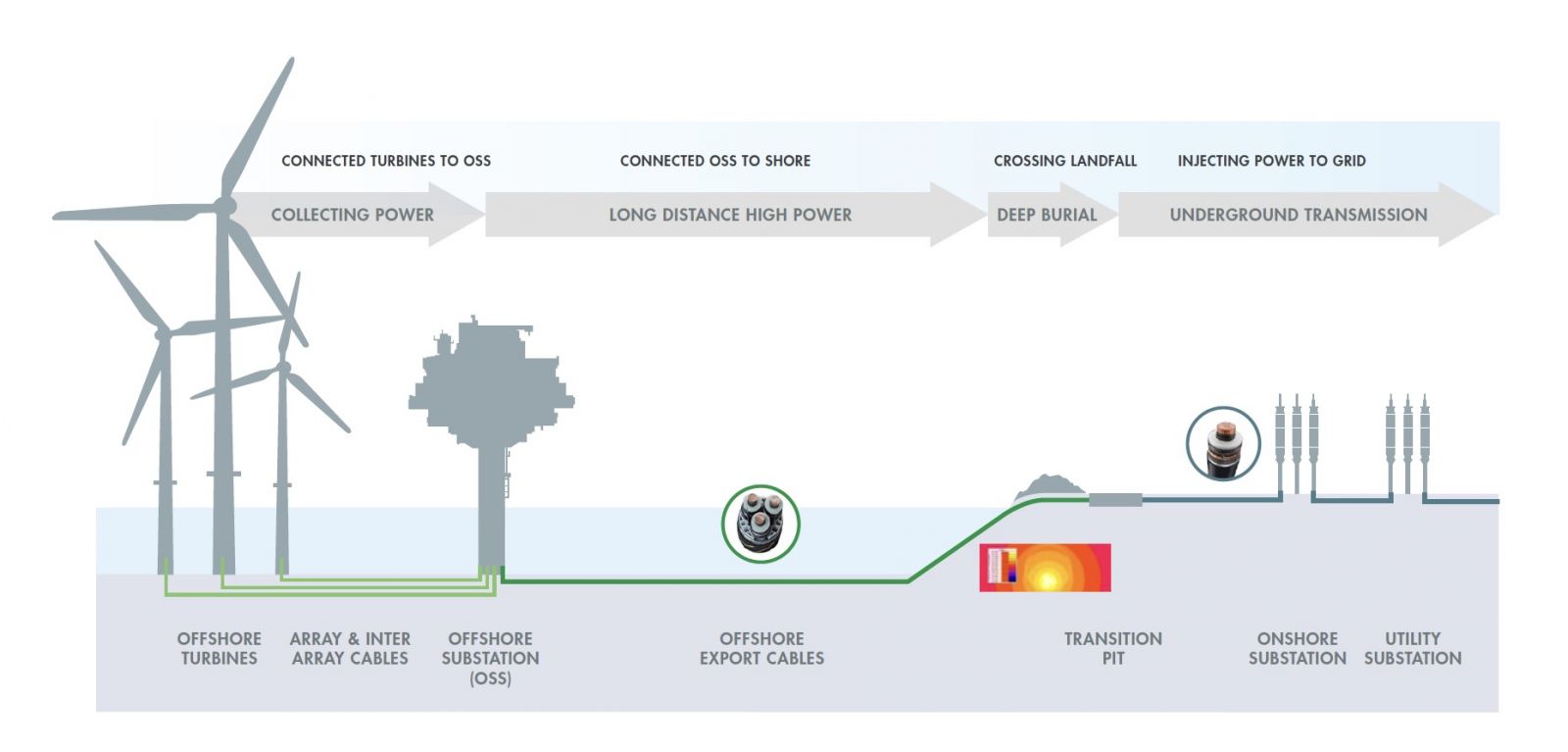

Bottom-fixed offshore wind farm and submarine electric power cables technology

The outer continental shelf off the East Coast possesses the same strong winds and extended shallow waters as the North Sea. For the foreseeable future, offshore wind turbines will be anchored to the sea floor (around 150- to 200-feet deep) in arrays, and medium voltage electric cables (called array cables or inter-array cables) will lay buried at the bottom of the ocean to collect the energy from the turbines, and send it to one or more offshore substations. From here, high voltage power cables (called export cables), also buried at the bottom of the ocean, will transport the power to the shore.

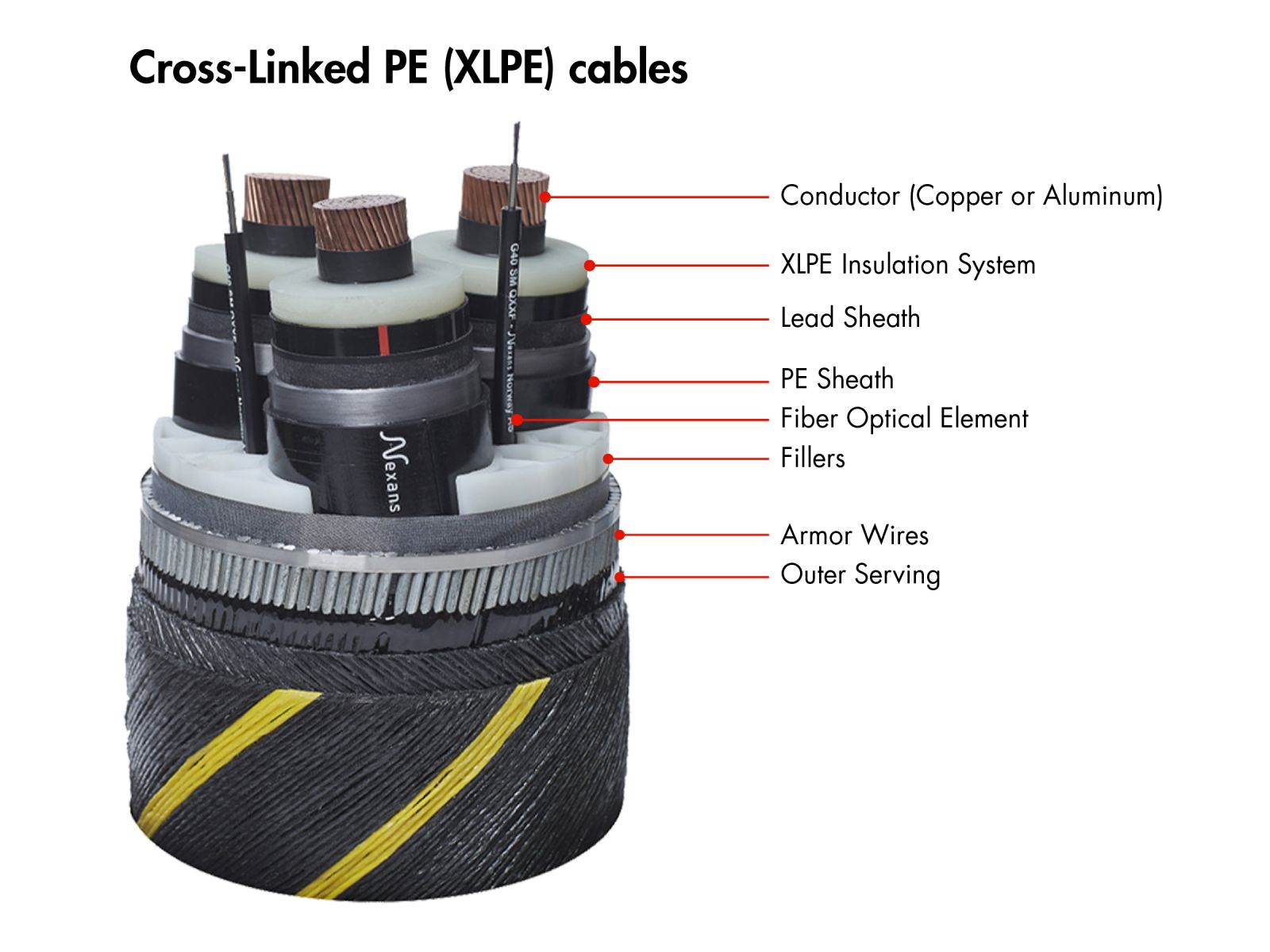

Export cables carry a lot of power at a higher voltage than ever before - between 220kV and 230kV for alternating current (AC) or 320kV for direct current (DC). They are made of copper or aluminum conductors electrically insulated with a crosslinked polyethylene. Their insulation must be protected from moisture with a stringent water barrier. That barrier is made by extruding a layer of lead (called lead sheath) over the cable insulation. On top of that layer, a polyethylene jacket is added to protect the lead sheath integrity and block lead migration. The insulated cables (called a phase for AC, and a pole for DC) can then be armored, or 3 phases can be assembled concentrically to form an AC 3-core cable and then be armored. The purpose of the armor is to protect the jacket from external damage. The armor itself is usually made of one or more layers of steel wires, and then one or more layers of yarns to protect the steel wires.

Export cables carry a lot of power at a higher voltage than ever before - between 220kV and 230kV for alternating current (AC) or 320kV for direct current (DC). They are made of copper or aluminum conductors electrically insulated with a crosslinked polyethylene. Their insulation must be protected from moisture with a stringent water barrier. That barrier is made by extruding a layer of lead (called lead sheath) over the cable insulation. On top of that layer, a polyethylene jacket is added to protect the lead sheath integrity and block lead migration. The insulated cables (called a phase for AC, and a pole for DC) can then be armored, or 3 phases can be assembled concentrically to form an AC 3-core cable and then be armored. The purpose of the armor is to protect the jacket from external damage. The armor itself is usually made of one or more layers of steel wires, and then one or more layers of yarns to protect the steel wires.

On the contrary, array cables - nowadays between 66kV and 69kV in AC - do not carry a great amount of power, which means that limited water penetration into the cables' insulation will not cause electrical insulation failures. Such designs are typically known as wet designs; they do not require a lead sheath, only a jacket and armor to protect the insulation and the jacket.

One of the challenges with export cables is that carrying a lot of power also generates heat inside the cables. To ensure reliable performance, the insulation of any cables cannot be heated above a certain threshold of temperature for extended period of times. For AC cables, 90â° Celsius is the threshold above which the crosslinked polyethylene insulation will degrade. The heat must be thermally dissipated - this is helped by the cool environment at the bottom of the ocean where the cables lay buried.

Because the power carried by export cables in operation have steadily increased over time (~400MW AC, >900MW DC), the issue of heat dissipation has become more and more critical. This has forced operators to monitor the temperature of the export cables in operation to detect if any parts of the cables come under stress, or are subject locally to variations in ambient temperature or change in thermal dissipation conditions. Temperature monitoring is done by incorporating optic fibers inside the export cables, and connecting those fibers to a distributed temperature sensing system (DTS) that uses the fibers as linear sensors. These additional safeguards represent only marginal costs for the export cables, and have the added benefit of allowing end-to-end data communication between the substation offshore and the one onshore that connects to the grid.

As the need for renewable energy continues to increase globally, work has begun by several submarine cable manufacturers to provide the next generation of export cables that will carry up to 2 GW in DC to onshore grid connections. Those "next level" submarine cable systems will allow for larger wind farms further from shore. The first of those new cable systems will likely be deployed in Europe, allowing U.S. projects and their local supply chain to leverage the experience gained there.

The looked over last step: Cable Installation

Once the cables have been engineered, manufactured in very long lengths, and tested for the required maritime qualities outlined above, they will need to be laid and buried at the bottom of the ocean. The ability to lay and bury them underwater with high precision across difficult geologies is crucial. It calls for advanced deep-water vessels that can micro-route very long HVAC and bundled HVDC cables weighting up to 10,000 metric tons per load, and use advanced burial tools like water jetting ROVs. Such vessels are currently being built; they will minimize offshore jointing requirements as well as potential seabed modification, which represent significant technical and commercial challenges. In addition to a high level of safety and redundancy built into their design to guarantee high "uptime," these vessels will also have the capacity to undertake long-range and long-duration operations without the need to pause to reload supplies.

The opportunities to develop offshore wind farms has reached U.S. shores, and momentum among the states will continue to grow as Americans become accustomed to seeing turbines off their coasts - and appreciate the clean energy benefits they provide. A critical component to their deployment, and the success of the offshore wind industry, will be the unseen submarine cables that deliver the clean energy to the mainland.

Maxime Toulotte is the Head of Technical Marketing of the Subsea and Land Systems Business Group in Nexans, where he has the responsibility to develop and maintain relations with technical and engineering departments of clients and partners for subsea high voltage cables.

Nexans | www.nexans.com

Author: Maxime Toulotte

Volume: 2020 September/October

.jpg?r=3077)