Cold Cash: How Thermal Energy Storage Can Cut the Cost of Commercial Refrigeration

Implementing thermal energy storage in commercial refrigeration and cold chain operations can save energy, time and money

The cold storage, refrigeration, and process cooling industries are often plagued with excessive operational expenses in order to keep things cool. A report by National Grid reveals that refrigeration constitutes an average of 54 percent of end-use energy consumption in supermarkets across the United States. Furthermore, the Freedonia Group recently forecasted that the global market for commercial refrigeration equipment is set to increase 4.5 percent per year through 2020, to $35.3 billion.

keep things cool. A report by National Grid reveals that refrigeration constitutes an average of 54 percent of end-use energy consumption in supermarkets across the United States. Furthermore, the Freedonia Group recently forecasted that the global market for commercial refrigeration equipment is set to increase 4.5 percent per year through 2020, to $35.3 billion.

The cold chain industry requires all transport and storage of materials to be maintained at particular levels of refrigeration; it's a demanding logistic segment due to its need for costly equipment, strict temperature regulation, and large energy load. The industry is also very conscious of uptime, since the loss of cooling doesn't just result in temporary end-user discomfort, but also financial impact from spoiled perishable goods, or dangerously low availability of medicines, vaccines, blood supplies, and organs. Cold chain operators, therefore, are always looking for new ways to balance the energy-intensive requirements of expensive, perishable consumer and medical products, while also managing energy consumption and cost.

Commercial refrigeration and process cooling are also industries in which the ability to manage energy consumption has attracted attention. Much of the growth in demand that the Freedonia Group reported is due to the necessary replacement of equipment, damaged by constant compressor cycling that refrigeration systems experience under typical operation. Instead of dealing with costly repairs, and to alleviate the burden of system maintenance, energy consumption, and cost, managers can profit by looking to a new alternative: cold thermal energy storage.

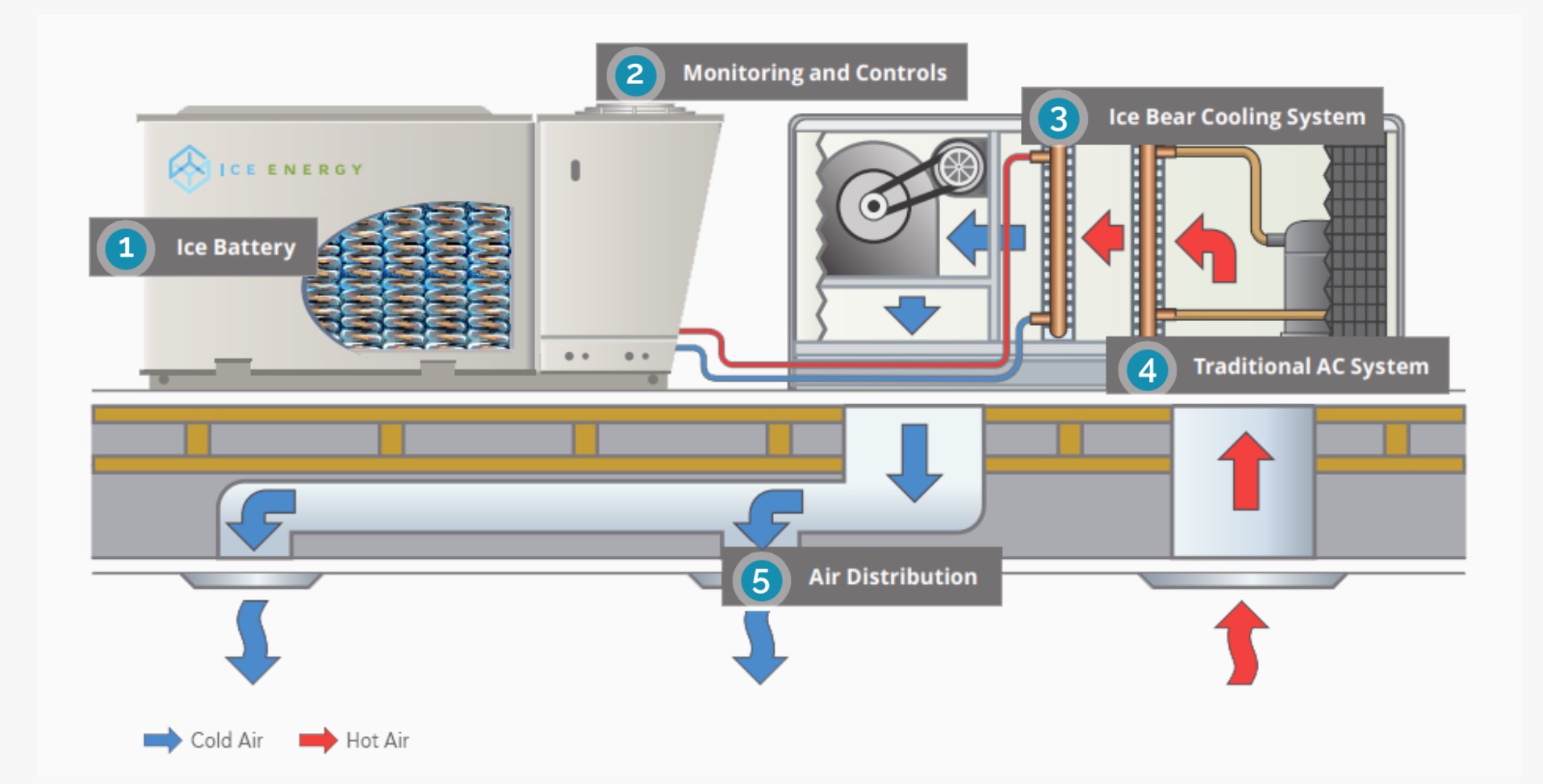

Thermal energy storage (TES) systems can help operators achieve multiple objectives in the cold-chain, commercial refrigeration, and process cooling industries: Increasing the reliability of their cooling redundancy, decreasing emergency energy requirements, managing utility demand charges and time-of-use rates, and providing improved humidity control.

What is thermal energy storage?

Thermal energy storage systems are not http://new. In fact, different shapes and forms of TES can be traced back as far as ancient Rome. High-efficiency, low-cost cold thermal energy storage systems, however, are a novel and innovative solution to today's cold chain and refrigeration energy management challenges.

Thermal energy storage systems are not http://new. In fact, different shapes and forms of TES can be traced back as far as ancient Rome. High-efficiency, low-cost cold thermal energy storage systems, however, are a novel and innovative solution to today's cold chain and refrigeration energy management challenges.

TES systems absorb energy when it is abundant and cheap, and deliver it during periods of peak demand, when it's more scarce and expensive. Thus, a TES-enabled system delivers energy at a fraction of the cost required to run a traditional cooling or refrigeration system. In regards to refrigeration and process cooling, this translates to a 75 percent reduction in compressor cycling during the highest demand periods of the day.

Identifying the Application

Modern implementations of cold thermal energy storage have been traditionally divided into two distinct categories. The first includes large-scale applications, in which the TES system is custom designed for the application. This is typical for skyscrapers or hospital buildings. The second addresses smaller-scale applications, in which pre-sized TES devices are purchased off-the-shelf, and retrofitted to the system. This includes smaller commercial buildings or residential applications.

For process cooling and refrigeration applications, a TES system can be incorporated into single-stage and variable refrigerant flow (VRF) systems, both of which are used in commercial and residential HVAC and commercial refrigeration. In these cases, the TES system can seamlessly integrate with existing supermarket, commercial refrigeration, or process cooling chillers. Ideally, it can also be used as an independent source of cooling for intermittent, or batch, applications that only run a few hours of the day.

Defining Real World Value

From an economic standpoint, using a TES system to shift usage to off-peak can generate significant end-user savings. One such system, located at a hair- and skin-care product laboratory in Riverside, California, has cut the end-user's electricity bill by $3,200 a month.

Another use case of particular value to the process and cold storage industries, is the availability of low-power, high-quality backup cooling during power interruption. In standard designs, a back-up generator sized to handle mission-critical duties needs to be available to take over at a moment's notice. A high-efficiency refrigeration and process cooling solution helps to achieve this by drastically decreasing power consumption requirements. This allows the system designer to potentially eliminate cooling from the generator load, by bundling the TES system with an appropriately sized chemical battery.

Today, there are a handful of TES solutions for supermarkets, process cooling, and the general commercial refrigeration market, which can be used in applications as diverse as cold room air conditioning (including 0ËšF cold rooms) and fermentation process cooling in wineries, breweries, or distilleries. With the availability of these new, high-efficiency TES systems, cold storage operators can now leverage the technology to increase the reliability of their systems, cut operating costs, and decrease CO2 emissions - all without breaking the cold chain.

Dr. Marcel Christians serves as Ice Energy's Chief Technology Officer. He currently leads Ice Energy's effort to develop a comprehensive suite of energy storage, cooling and heating solutions for global residential and C&I markets covering the refrigeration and comfort cooling spaces. Prior to joining Ice Energy, Marcel worked at Carrier Corporation's Technology and Components Division, where he designed and developed disruptive heat transfer technologies and systems for the chiller market. Marcel holds a Ph.D. in Mechanical Engineering from the École Polytechnique Fédérale de Lausanne, in Switzerland, where he studied under the tutelage of world-renowned heat transfer expert Prof. John Thome. He graduated Magna Cum Laude from the University of Pretoria, in South Africa in 2005 with an M.Eng. in Mechanical Engineering.

Ice Energy | www.ice-energy.com