Grocery Stores Go 'Beyond Batteries' with Thermal Energy Storage

As the energy storage market takes off, many players are quickly realizing that lithium-ion based systems have their limits in terms of what types of applications for which they are best suited. For the industry as a whole to meet forecasts of 29.4 GW by 2020 (according to Navigant Research), the market needs specialized, low-cost, behind-the-meter energy storage systems, tailored for specific sector needs and uses.

One example of an industry that could thrive on a specialized approach is grocery stores and cold storage facilities. By looking at the electricity load curves for a grocery store and an office building, it's clear that each uses energy in distinct ways.

The office building has a "common curve", where the load increases and reaches its peak near mid-day when the building is most occupied, and demand for building services such as lighting, HVAC, elevators, and other loads, are also at their peak. The variability in demand for these services creates sharp peaks; the highest 15-minute interval can establish the energy price for that facility for the entire month, due to peak pricing structures.

In comparison, the grocery store's load curve is relatively smooth, with lower spikes, but a higher continuous use of energy. The reason this load curve looks so different is because the central refrigeration system, which represents up to 55 percent of the energy load, runs consistently throughout the day and night. This reduces the net variability of the building's load. The other major loads after refrigeration, such as HVAC and lighting, ramp up when the store opens and closes, which also reduces the variability found in most other commercial and industrial building classes.

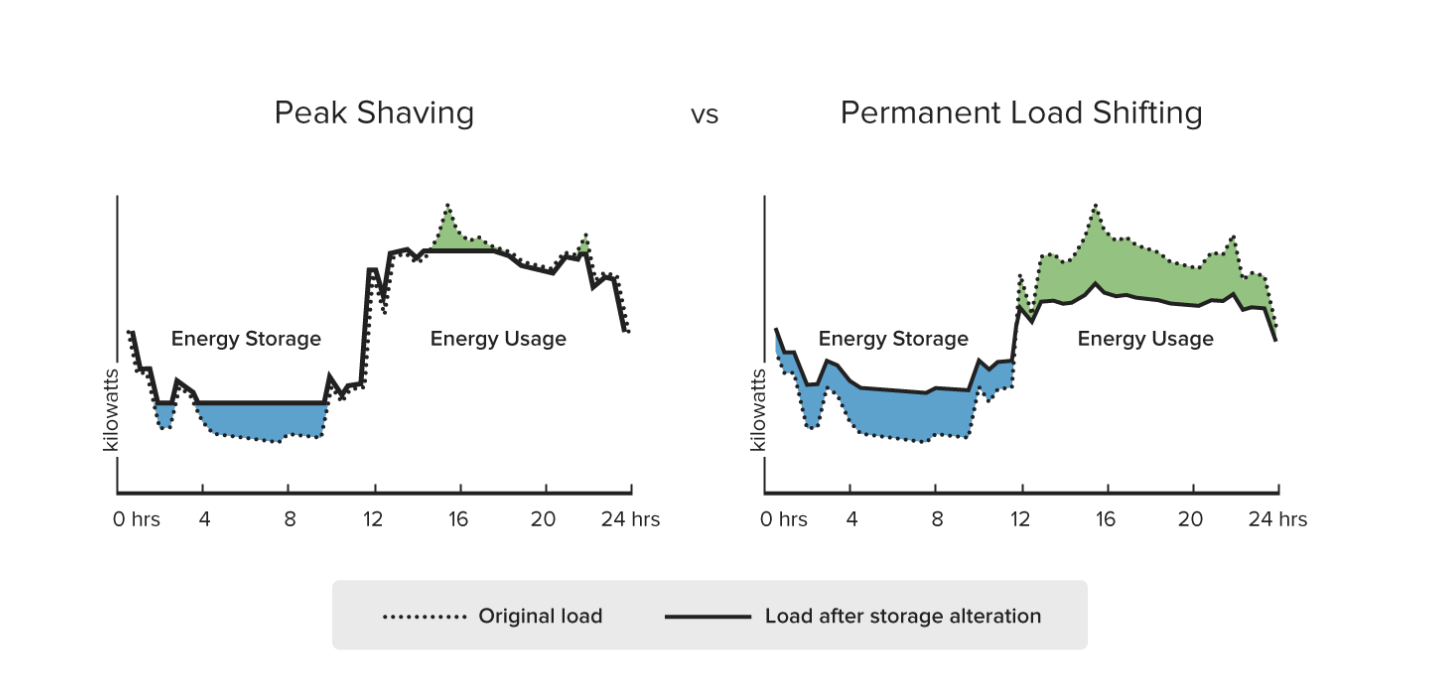

Diagram Summary: this diagram looks at an average supermarket load profile in Northern California. Because the profile is  relatively smooth, peak shaving to create utility bill savings, depicted in the diagram on the left, is highly limited and doesn't create enough savings to get the attention of supermarket owners. By contrast, to create significant savings, an energy storage system needs to shift a much larger amount of load, for a longer period of time, depicted in the diagram on the right.

relatively smooth, peak shaving to create utility bill savings, depicted in the diagram on the left, is highly limited and doesn't create enough savings to get the attention of supermarket owners. By contrast, to create significant savings, an energy storage system needs to shift a much larger amount of load, for a longer period of time, depicted in the diagram on the right.

Electrochemical batteries are often utilized to reduce expensive peak demand charges, a shorter-duration, higher power storage application. However, in order to present a compelling business case to a supermarket owner, the energy storage industry needs a technology capable of handling a large refrigeration load with enough efficiency to shift a store's base load for at least four to six hours during the day. This is what makes groceries, food warehouse, distribution, and manufacturing facilities unique in their energy management needs.

The good news? Existing solutions address the unique needs and physics of the broad commercial and industrial building sector.

By using a thermal energy storage solution, businesses with large refrigeration-based energy loads can reduce their total peak electricity demand by up to 40 percent. Refrigeration Batteries can shift 100 percent of a refrigeration system's medium temperature refrigeration load off peak for over six hours each day. They leverage the existing refrigeration system's excess capacity to "store cooling" at night by freezing tanks of salt water. During afternoon peak hours, Refrigeration Batteries use the frozen tanks to supply refrigeration services to the building, eliminating the need to run energy-intensive compressors and condensers (supermarkets are three times more energy intensive that any other retail facility and up to 60 percent of the electricity load is a attributable to refrigeration - reference). Refrigeration batteries are non-invasive, modular retrofits operating in parallel with existing refrigeration systems to shift daytime energy loads to less expensive off-peak hours. They can also provide backup cooling to reduce uninsured food spoilage during power outages, an expensive and growing problem for supermarket owners. Installation of a refrigeration battery does not require physical or programming modifications of existing equipment, and appears to the existing refrigeration system just like a new display case.

Other manufacturers also use frozen water to provide cooling services for rooftop air conditioning units. One example is a thermal battery that attaches to one or more standard 5 to 20-ton commercial AC units. During off-peak hours, it freezes water to store cooling energy. During peak hours, stored ice provides up to four hours of cooling using only 5 percent of the power that otherwise would have been required. These units have been operating in the field since 2005, providing over 34 million hours of cooling to governments and businesses in a variety of industries.

Meanwhile, a flexible, dispatchable and cost effective energy storage system converts off-peak electricity to heat, and stores it in heating elements contained within high-density ceramic bricks. This system can store heat for long periods of time, and deliver it through space or water heating as needed. If a business utilizes a source of renewable energy, the system will allow it to harness the variability and full output of the solar or wind power generation system. And with available remote control operation, it's possible to access the systems' built-in safety and monitoring devices from anywhere to ensure consistent load management and affordable energy costs.

Beyond the low cost of the water-based storage mediums (called phase change materials or PCMs), these energy storage solutions offer a variety of benefits over other types of chemistries, such as lithium-ion, lead acid, or flow batteries. As a storage medium, frozen saltwater has a proven long life span, and most previous applications of this storage method have been in the field for decades. This thermal storage method avoids many of the often hidden, balance of systems costs that electrochemical or flow batteries must account for, such as power converters, fire suppression, and interconnection charges/regulatory time. This substantially reduces the equipment and installation costs for the customer and rollout time. Meanwhile, the longer discharge durations are more economical, making energy storage possible in facilities that have smoother load profiles (e.g., buildings with large baseload electricity requirements). This makes behind-the-meter energy storage more attainable in many types of facilities that cannot be served by other battery chemistries.

As the energy generation and consumption model continues to modernize, a "one-size-fits-all" approach to storage technology could leave sectors such as grocery stores and cold storage facilities out of storage advancements, unable to profit from the suite of distributed energy resources (DERs) leading C&I players are deploying. If we truly want to realize the opportunity for grid modernization, the energy storage industry as a whole must understand, develop, and promote technologies addressing the specific energy usage requirements of each sector.

Ryan Adelman is Chief Commercial Officer for Axiom Exergy, a thermal energy storage company focused on making the world's energy systems smarter and more efficient, specifically for supermarkets and cold storage facilities. Prior to joining Axiom, Ryan led the development of Siemens Retail and Commercial Systems, establishing Siemens as a global leader in enterprise, light commercial energy management services. Ryan has an MBA from the University of Chicago Booth School of Business and is the former Western Division Strategy Chair for Cleantech Open.

Axiom Exergy | www.axiomexergy.com

Volume: 2017 May/June