The Facts of LiFe For Energy Storage: lithium-ion versus flooded lead-acid batteries

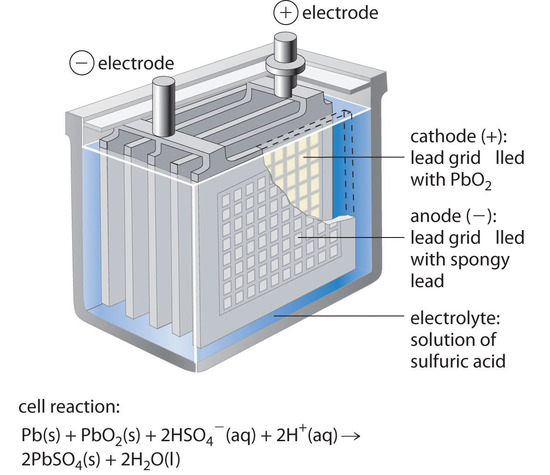

While lithium-ion batteries have been proven safe, reliable and economical for small electronic devices, the push for their use in energy storage has sparked debate on their actual cost and performance. Many advocates claim that lithium-ion batteries are more cost effective than, and offer a safe alternative to, the lead-acid batteries currently used for storage. According to battery industry experts, however, we're not getting the whole story.

One such expert, Dr. Mike McDonagh, points out the half-truths put out by the Lithium industry: "Energy densities of current lithium-ion battery chemistries are given at around three to five times the gravimetric and volumetric energy density of lead-acid at the cell level, which in part explains why the older technology has been all but ignored. Factor in the connectors, spacing in a battery pack, the control and safety equipment, battery management system, fire control, and cooling equipment which are required for the safe operation of larger lithium-ion batteries, and the net result is that an installed working lithium-ion battery will have a working capacity less than one-half its nameplate value."

Comparing The Actual Costs

Comparing The Actual Costs

"The performance data given in comparison between lithium-ion and flooded lead-acid batteries is often done with a single cell," said McDonagh. "This type of comparison, however, does not include any additional components needed for proper operation. The data very conveniently ignores the additional architecture required for safe operation in most installations and it is safety that manufacturers claim are their greatest concern."

Fred Wehmeyer, VP of engineering at one of the largest battery manufacturers in the U.S., urges anyone making a comparison to add in all of the costs. "A single LiFePO4 cell has a nominal voltage of 3.2-volts, thus requiring eight cells in series for a 24-volt battery pack - double that for a 48-volt system," said Wehmeyer. "The average retail price of one 100 Ahr (amp-hour) cell is $155, putting the pack cost around $2480 for a 48-volt system. A compatible BMS and charger cost $290 and $1075 respectively. Altogether, a conversion would cost $3845 and will provide a reported 2000 cycles at a lower energy content of 5120 watt-hours vs 10,500 watt-hours for a comparable flooded lead-acid battery pack costing about $800. The lead-acid battery would provide twice the runtime for 1/5 the cost."

Maintenance Considerations

One of the reasons for lithium-ion's allure is the maintenance involved with flooded lead-acid batteries. Removing each battery vent for inspection and watering is burdensome to both homeowners and businesses. To alleviate these tasks, several companies offer systems that allow a complete battery pack to be filled within seconds. Manufacturers have also developed new technologies that indicate when the batteries need water. "Smart valves", for example, replace the cell caps on the battery, and feature visual indicators (red or green LEDs) that tells you if the battery pack is properly filled, or needs water.

Environmental Impact

Environmental Impact

The environmental impact of batteries must also be addressed in comparing lithium-ion and flooded lead-acid technology. "When you take into account environmental cost and safety, on top of the performance issues, the lithium-ion case over lead-acid doesn't stack up to anything as manufacturers would have you believe," said McDonagh. "You need to look very carefully at their numbers. Lead-acid is a safe, sound and, sadly, overlooked technology that's 150 years young and completely recyclable."

According to the Battery Council International (BCI), the trade association for manufacturers of original equipment and aftermarket batteries, the recycling rate of flooded lead-acid batteries in the United States is greater than 99 percent. This recycling rate is better than glass, aluminum, and any other material currently recycled. The International Lead Association also agrees that lead-acid batteries are recycled at the highest rate of any commercial product, but not without some new concerns. They warn that, with the increase of lithium-ion battery use, the introduction of these batteries into the lead recycling system has resulted in a number of safety incidents.

"The increase of lithium batteries finding their way into the lead-acid battery recycling stream presents safety issues for recycling facility operators," says Wehmeyer. According to the BCI, when lithium batteries are mixed with lead-acid batteries in the recycling process, there is an increased risk of fires and explosions, which can occur during transport, storage, battery breaking, as well as during the smelting processes of used lead-based batteries.

To combat this, the U.S. Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC) are proposing to develop standardized labels that are color-coded, to allow for better identification between lead-acid and lithium-ion batteries. "In the end, not only are lithium batteries not currently being recycled, but consumers would have to pay to dispose of spent lithium vehicle batteries," said Wehmeyer.

Most battery experts agree that lithium-ion has its place and is safe for many uses, but the success doesn't necessarily translate into its safe and efficient use in other industries; at least for the moment.

Dan Sanchez is a journalist, author, and media content provider to a variety of energy and automotive companies.

U.S. Battery | www.usbattery.com

Volume: 2018 March/April