If Henry Ford Manufactured PV Inverters

If Henry Ford Manufactured PV Inverters

How harmonic neutralization helps harvest more power and reduce BoS costs

When we think about the agents of change in the history of industry and technology, Henry Ford's name always comes to mind. In addition to revolutionizing automobile production, Mr. Ford left us with several nuggets we can apply to the technological advancements we see in the market for solar inverters; the devices that convert the variable direct current (DC) output of a photovoltaic (PV) module into an alternating current (AC) at utility frequency which can be fed into a commercial electrical grid, or used by a local, off-grid electrical network.

Mr. Ford once said "If you always do what you've always done, you'll always get what you've always got."

As such, to make utility-scale solar plants economically appealing sources of power, we'll need to take a more novel approach to the inverter piece of the PV plant to drive a step-wise reduction in the overall balance of system (BoS) cost. Over the past decades, market forces have driven the cost of PV modules down to the point where little opportunity for cost savings exist. As a result, any further economies need to be found elsewhere. Harmonic Neutralization (HN) is a breakthrough power inverter technology for utility-scale solar, wind, or mixed solar/wind installations allowing PV operators to drive those needed economies. This new approach to inverter design helps break through the AC power-output ceiling found in the traditional, utility-scale PV inverters which rely on the pulse-width-modulation (PWM) method of power conversion.

PWM is a derivative of technology developed for AC motor controllers. With PWM, transistors inside an inverter are switched thousands of times per second with variable pulse durations to modulate current into a sinusoidal form. This technology is effective for small and medium inverters, but does not scale up well to the higher megawatt power ranges needed for utility-scale power conversion. The main reason for this limitation are the high switching losses inherent in PWM technology which can cause semiconductors to overheat in the absence of proper cooling.

A conventional PWM technique generates sinewave current from a DC source by commutating switching devices to produce a series of high frequency pulses (generally 3,000 to 15,000 Hz for larger systems) of variable width running through output inductors integrated to produce near sinewave current. By contrast, HN technology allows switching of DC sources at the frequency of the electrical grid (50/60 Hz), anywhere from 60 to 300 times lower than PWM, while still generating a sine wave current meeting IEEE 519 standards.

A conventional PWM technique generates sinewave current from a DC source by commutating switching devices to produce a series of high frequency pulses (generally 3,000 to 15,000 Hz for larger systems) of variable width running through output inductors integrated to produce near sinewave current. By contrast, HN technology allows switching of DC sources at the frequency of the electrical grid (50/60 Hz), anywhere from 60 to 300 times lower than PWM, while still generating a sine wave current meeting IEEE 519 standards.

HN allows inverters to be built with several inverter modules connected in parallel to a common DC bus. Each inverter module is synchronized with the grid frequency, however with specifically calculated lead or lag phase angles between output current and grid voltage, uniquely set for each inverter module in the system. The output AC currents are then summed on a phase shifting transformer to return phases of all currents to a single combined output, with adjustable phase to the grid's voltage. This maneuver sums the fundamental currents in all of the inverter windings into the grid winding but neutralizes the higher harmonics and prevents injection of those harmonics into the distribution grid. As a result, HN allows for simpler solar array topology, lower initial installation costs, increased energy yields, and lower power losses.

The HN approach to inverter design has a number of technical benefits over PWM, including:

- Smaller size, higher power density, and lower equipment cost per MW rating as a result of utilizing very large semiconductors.

- High efficiency (99.5%) achieved through low (50/60 Hz) switching frequency - hundreds of times lower than conventional PWM inverters.

- Unsurpassed reliability from simplified construction: Several three phase heavy-duty inverter modules operate concurrently from the same DC source into the same load assuring even the entire loss of one module only minimally affects power generation.

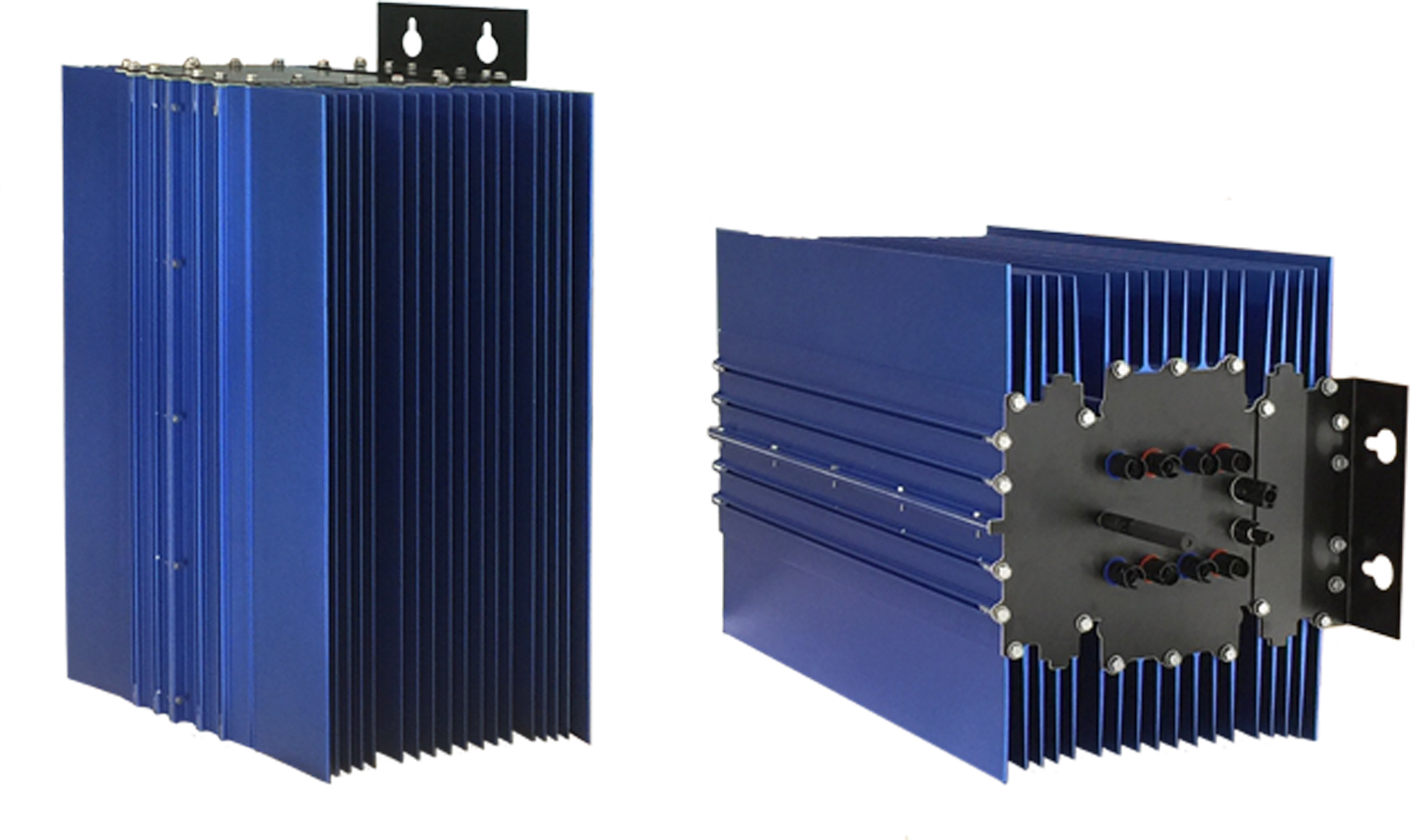

With HN, the benefits don't stop at the inverter level. Where HN really gets compelling is at the BoS level. The key to high-energy yield from HN-based inverters is granular, optimized PV power harvesting. The HN system achieves this via string-level DC to DC optimizers. These string level optimizers provide maximum power point tracking (MPPT) to minimize the impact of uneven soiling, cloud cover, sporadic damage, and module degradation. These powerful DC to DC optimizers replace the dizzying amount of combiner boxes found in a typical utility-scale PV plant. Additionally, this approach drives the BoS cost down further by decreasing both the quantity and size of the DC cables needed to complete the installation.

With HN, the benefits don't stop at the inverter level. Where HN really gets compelling is at the BoS level. The key to high-energy yield from HN-based inverters is granular, optimized PV power harvesting. The HN system achieves this via string-level DC to DC optimizers. These string level optimizers provide maximum power point tracking (MPPT) to minimize the impact of uneven soiling, cloud cover, sporadic damage, and module degradation. These powerful DC to DC optimizers replace the dizzying amount of combiner boxes found in a typical utility-scale PV plant. Additionally, this approach drives the BoS cost down further by decreasing both the quantity and size of the DC cables needed to complete the installation.

Another quip famously attributed to Mr. Ford is, "If I had asked people what they wanted, they would have said faster horses." It's understandable why this sort of change in thinking has not come from the traditional inverter manufacturing community. After all, one of the great challenges in implementing any utility-scale project is the issue of bankability. In this environment, project sponsors tend to be risk averse in straying from "tried and true" solutions and suppliers, which can place a greater focus on evolutionary technologies over perhaps revolutionary ones. However, this is the sort leap we'll need to take in order to help utility-scale PV projects achieve their ultimate promise.

Dr. Oleg Fishman is the chairman of Alencon Systems, LLC.

Dr. Oleg Fishman is the chairman of Alencon Systems, LLC.

Alencon Systems, LLC. | www.alenconsystems.com

for production only: image captions

SOLAR_AlenconSystems_Image1.jpg: Alencon's GRiP invertors, available in 2.5 MW modules, use a unique, patented Harmonic Neutralization to improve the yield and reduce the cost of utility-scale PV installation.

SOLAR_AlenconSystems_Image2.jpg: The wave forms of inverter currents from each of the four inverter modules shown. The blue, green, yellow, and magenta oscilloscope tracing show the phase A distorted currents of each inverter module. The red tracing in the bottom of the picture demonstrate a clean sine wave of harmonically neutralized current delivered into the grid.

SOLAR_AlenconSystems_Image3.jpg: SPOT: a DC to DC string level optimizer used in conjunction with an HN-based inverter. The SPOT steps up voltage transmission to the inverter from a string of PV module and also provides maximum power point tracking (MPPT).

Volume: 2016 September/October

.gif?r=9926)

.jpg?r=5233)