Dynamic Grid & Market Conditions: Challenge PV monitoring systems

Solar PV has, certainly, secured a prominent position in the utility power-generation sector. Rapidly growing solar portfolios span across all continents and many countries—often with diverse grid connection regulations and ownership models for electricity distribution. Though the growth of the industry is impressive, development has also spurred new demands on what’s commonly known as a power plant’s “monitoring system.”

Solar PV has, certainly, secured a prominent position in the utility power-generation sector. Rapidly growing solar portfolios span across all continents and many countries—often with diverse grid connection regulations and ownership models for electricity distribution. Though the growth of the industry is impressive, development has also spurred new demands on what’s commonly known as a power plant’s “monitoring system.”

Gone are the times when simple condition monitoring, allowing remote visualization of the plant status, would satisfy a plant owner’s requirement for information. And, this applies all the more to the first-generation monitoring techniques, which were tightly connected to a particular inverter type, and weren’t open to expansion and data exchange with other information systems.

But, what is the force driving the need to look beyond the performance of individual components in the solar plant? A major factor is the demand to aggregate many individual plants into larger plant portfolios, so they can contribute power reserves to the power grid as ancillary services.

Grid integration

The need for a controlled power-feed into distribution and transmission grids has shifted the emphasis from what was once a useful, but a mere monitoring system, into a mature monitoring, control, and supervision system design. Such systems now rely on in-depth performance data gathered at a plant. The control aspects of such a plant-encompassing scheme must ensure the facility can meet a system operator’s grid code flexibly. These codes not only vary from country to country, however, but quite often even between regions and states within a country.

The need for a controlled power-feed into distribution and transmission grids has shifted the emphasis from what was once a useful, but a mere monitoring system, into a mature monitoring, control, and supervision system design. Such systems now rely on in-depth performance data gathered at a plant. The control aspects of such a plant-encompassing scheme must ensure the facility can meet a system operator’s grid code flexibly. These codes not only vary from country to country, however, but quite often even between regions and states within a country.

The provision of grid support services, such as active and reactive power control, contribute to grid management and stability at a local level, especially in regions with a large amount of decentralized solar PV production.

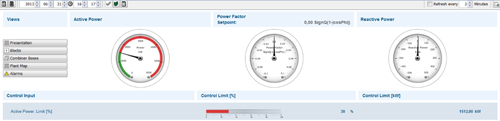

Nonetheless, providing frequency and voltage support is not new for PV systems. In fact, today’s dedicated park controllers, typically installed in transmission stations close to the grid connection point, are even capable of controlling a cluster of solar plants of different sizes and with different inverter equipment (see Figure 1). However, as solar PV’s share in the power mix is growing rapidly, these plants will gradually take a more active role in providing additional ancillary services for grid balancing.

Some of these, such as contracts for supplying upward power reserves in the day-ahead and intraday markets, can be a valuable source of additional revenue for a plant owner. The same goes for a dispatcher or trader, who would typically aggregate several power generation plants into one virtual power plant.

But, how does this emerging trend—the one of solar PV assuming a serious role in grid stabilization and in power dispatching and trading—affect the role of the monitoring system?

A real-time database

Real-time, high-resolution plant data, maintained, and analyzed over the plant’s entire lifecycle, is the essence of all visualization, supervision, and grid feed functions. It’s vital for controlling and tuning the plant’s response to changing grid and market conditions. Therefore, the bedrock of the monitoring system is the instrumentation installed in the plant.

Real-time, high-resolution plant data, maintained, and analyzed over the plant’s entire lifecycle, is the essence of all visualization, supervision, and grid feed functions. It’s vital for controlling and tuning the plant’s response to changing grid and market conditions. Therefore, the bedrock of the monitoring system is the instrumentation installed in the plant.

In fact, the quality of sensors and measuring instruments plays a crucial role. After all, these devices have to constantly quantify the status and performance of all functional groups, components in the plant, and the state of the weather—including, the primary source of energy, the solar irradiation.

Analysis & planning

The software part of a monitoring system—or, the remote display and supervision platform and everyday working tool of the control room, of the O&M manager, and of the power dispatching center—ideally needs to be enhanced by advanced tools that provide power production control and planning.

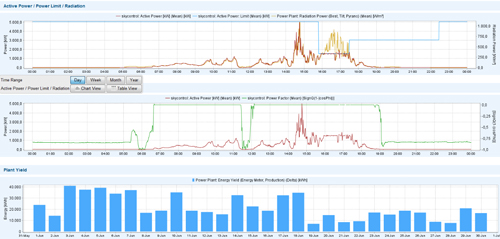

These control and planning functions, in turn, entail real-time performance analysis, reporting, and forecasting. The provision of ancillary services at a high-confidence level relies on production analysis and forecasts, as well as on the evaluation of forecast errors.

This whole range of new tasks, therefore, necessitates extra tools, such as:

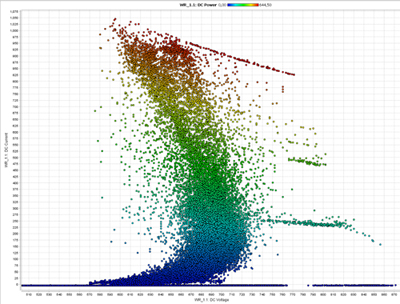

• Tailored XY diagrams, allowing a free selection of inputs on each axis for the creation of 2D and 3D scatter plots and in-depth diagnostics (see Figure 2);

• Flexible reporting tools that allow convenient customization;

• Weather-model based production forecasts that are updated several times a day, supplying estimates of hourly production for up to seven days into the future;

• Self-learning algorithms interpreting historical plant, terrain, and weather data, while providing enhanced forecast accuracy over time; and

• Display, evaluation, and reporting of power curtailment and other control commands issued by the grid operator or the trader/dispatcher (see Figure 3).

Flexible user interface

Plant retrofits, data migration, plant pooling, virtual power plants—all of these developments are in the area of system integration and interoperability. For a quality, cutting-edge monitoring system this implies versatility: its user interface must remain agile and offer customizing options, such as dashboards, kiosk views, and interfaces to display information from external sources. In particular, the requirements for the communication and control interfaces with the system operator may vary greatly and demand a high degree of flexibility from a system.

Coming of age

Today’s PV installations have become full-fledged power stations. They must conform to industry standards, fit neatly into a country’s power generation landscape, contribute to grid stability, and adapt to different electricity dispatching and trading schemes.

Drawing on an in-depth plant information database, external data sources, and powerful computation tools, yesterday’s monitoring system is rapidly evolving into a powerful system for not just monitoring, but also for control, supervision, performance analysis, and production planning. However, owners’ renewables portfolios are typically distributed all over the world, and individual plants have to comply with different national requirements.

Therefore, a systems’ approach must not only offer proven standard functions, but must remain open and adjustable, and allow customization in line with the requirements of a particular country, application, and customer. Only such systems can truly be said to have come of age.

skytron energy GmbH

www.skytron-energy.com

Author: Monika Hennessen

Volume: March/April 2014

.jpg?r=4346)

.jpg?r=4240)

.gif?r=8224)