Winning the Lightning Race: A new frontier in blade protection

As wind turbines grow taller and storms intensify, lightning strikes have become an increasingly costly challenge for the wind energy industry. Turbines now stretch well beyond 160 meters at the tip, increasing their exposure to the atmosphere's most powerful natural phenomenon. In high-risk regions, some turbines are struck more than 10 times a year. Even a single strike can cause blade punctures, delamination, or — in rare cases — catastrophic structural failure.

Estimates suggest lightning-related damage costs the industry over $100 million annually in repairs and downtime. Traditional lightning protection systems (LPS), though effective in many cases, aren’t foolproof. They rely on surface-mounted receptors connected to internal conductors designed to direct the energy safely to ground. But field experience shows that upward lightning leaders — the ionized channels that initiate a strike — don’t always originate at these receptors. Instead, they often emerge from inside the blade itself, where they can burn through structural materials and compromise integrity before ever reaching the cloud.

This challenge has prompted a new generation of engineers to rethink lightning protection, not by trying to make blades invincible, but by increasing the likelihood that strikes attach where they’re supposed to: the external receptors.

*Figure 1: A wind turbine equipped with the new receptor-enhancing topcoat undergoes field testing during an active lightning storm. Field pilots in the U.S. are confirming the durability and performance observed in lab simulations. *

Redirecting the discharge

Recent research has focused on enhancing the electric field at the receptor location itself, giving it a better chance of forming the fastest, strongest upward leader. The faster this leader grows, the more likely it is to outpace competing leaders emerging from less protected areas inside the blade. In the milliseconds before a lightning strike, it’s a literal race for connection — and the first leader to connect with a downward leader from the cloud determines where the energy will flow. While many strikes begin with downward leaders from the cloud, there are also conditions — particularly in tall structures like turbines — where the process is initiated from the turbine itself. This “upward lightning” follows the same basic dynamics, and everything that follows here applies equally to that scenario.

A newly developed coating has emerged from this research. Designed for use around lightning receptors, this coating contains a proprietary mix of minute conductive particles suspended in a durable polyurethane matrix. As the surrounding electric field intensifies in storm conditions, these particles create localized patches of ionized air just above the surface — effectively “priming” the area for leader formation.

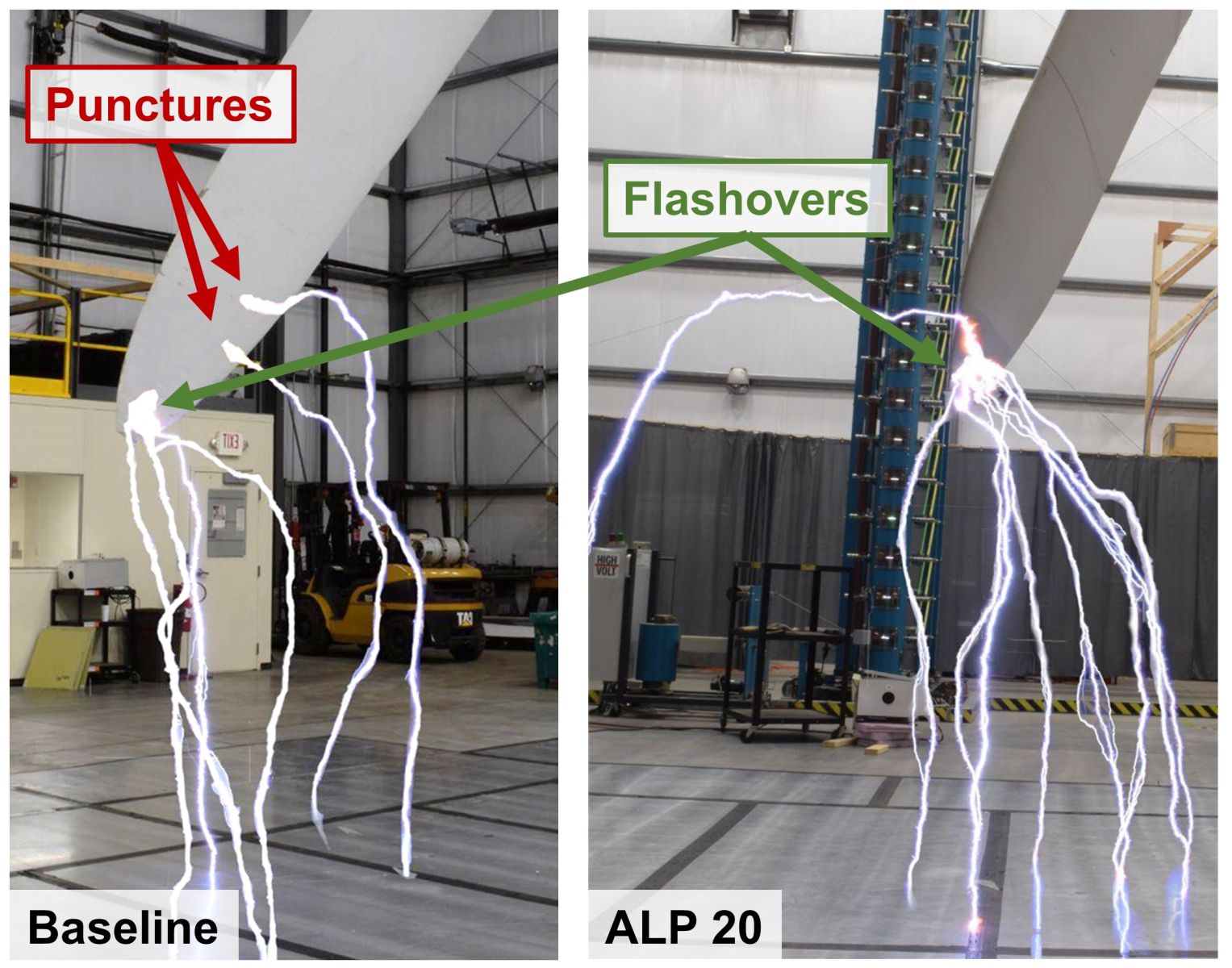

Lab tests have shown that blades treated with the coating generate upward leaders over four times faster than untreated blades. Because the coating isn't conductive like a metal paint, current flows through the ionized air — not through the coating itself — allowing it to survive multiple high-current strikes without degradation. Once applied, the coating does not need re-application and will last for the remaining lifetime of the blade.

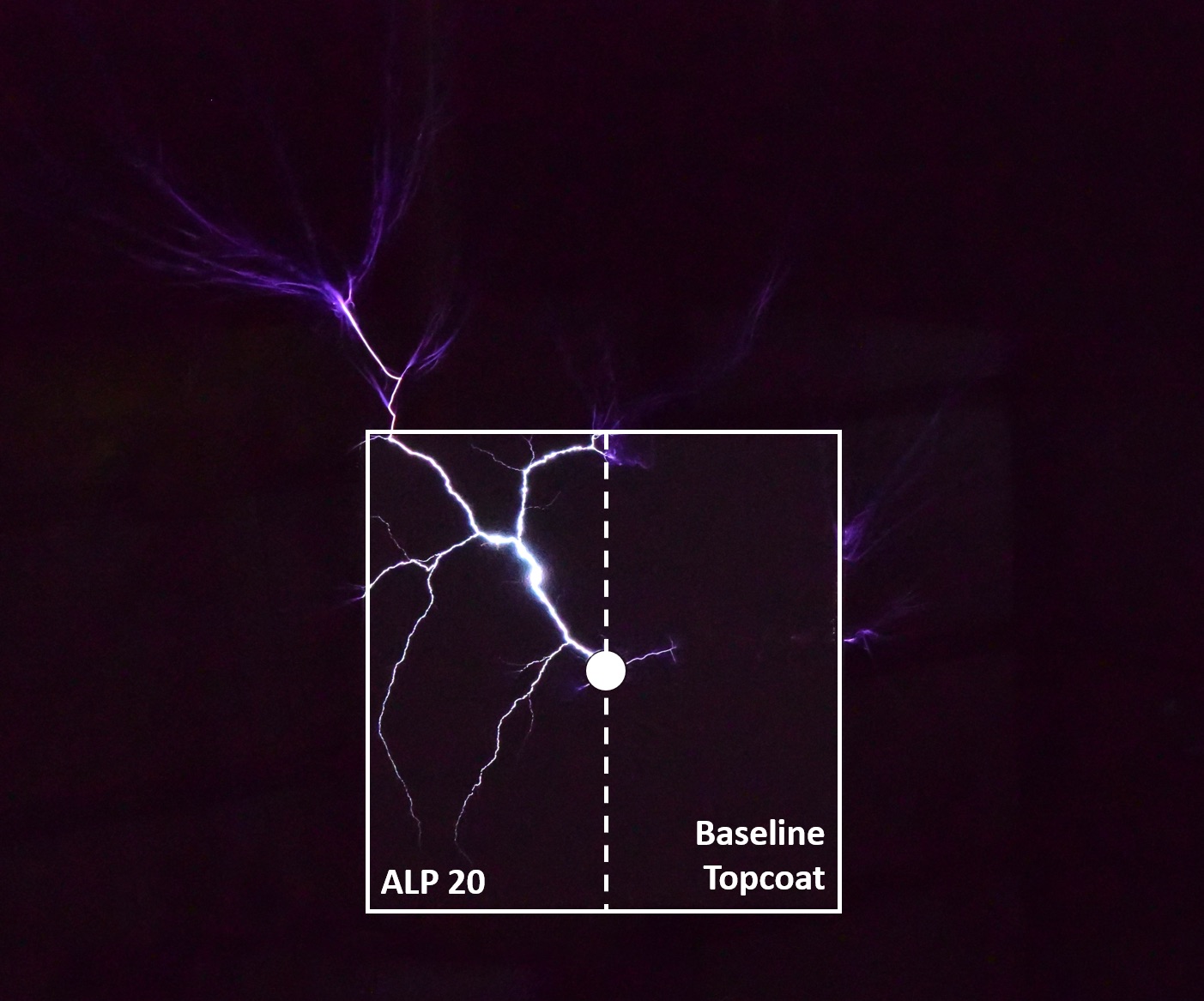

*Figure 2: High-voltage lab testing simulates electric fields at the moment before a lightning strike. A coated panel (left) shows earlier and stronger leader formation compared to the untreated side (right), increasing the likelihood of a safe strike.*

Real-world durability

To be viable in the field, any lightning mitigation solution must be robust, weather-resistant, and easy to apply. This coating was developed with those needs in mind. Its application process mirrors that of existing blade maintenance coatings: roughen the surface, apply two layers with a roller, and allow to cure. Technicians can apply it using rope access or bucket trucks during scheduled maintenance windows, and a single kit is sufficient for treating one blade.

Unlike traditional conductive materials that degrade with each strike, this formulation has withstood multiple 200-kiloamp laboratory discharges — among the most powerful simulated lightning events used in testing. After years of lab trials and accelerated aging, the coating shows no signs of cracking, flaking, or breakdown.

From lab to field: Real-world testing underway

While laboratory testing remains the gold standard for comparing lightning protection technologies under controlled conditions, field testing is essential for proving long-term durability and impact.

Two pilot studies are currently underway — one at a wind farm in the Mid-Atlantic and another in the Midwest. In each case, the coating was applied to select turbines, and the results are being monitored over multiple seasons.

Early findings have been promising. Drone inspections confirm coating adhesion and condition even after winter exposure, and operators report no lightning-related blade damage on treated units to date. As the studies continue, these field trials will help validate the projected 73 percent reduction in damaging lightning events observed in lab simulations.

*Figure 3: Composite photos of a turbine blade before and after coating application. The coating significantly improved lightning attachment at the receptor, eliminating damage during full-threat strike simulations. *

A smarter standard for protection

The physics of lightning attachment haven’t changed, but our ability to influence the outcome has. By shaping the electric field near receptors and encouraging stronger leader formation there, this new coating gives operators a low-cost, high-impact way to reduce damage without overhauling existing LPS infrastructure.

As the climate continues to shift and turbine designs push new limits, solutions like these may become part of the standard toolkit for blade protection not just for new installations, but as retrofit upgrades across the existing fleet. Avoiding a single major lightning-related repair can offset the cost of treatment many times over, especially when damage prevention means avoiding unscheduled downtime during high-wind season.

Lightning protection has come a long way since Benjamin Franklin first flew his kite. Today’s wind turbines need more than passive resistance — they need active guidance. That means winning the race to the cloud, one upward leader at a time.

Neal Fine is the CEO and co-founder of a renewable energy startup focused on advanced materials for wind energy and sustainability. He holds a Ph.D. from MIT in Marine Engineering and has over 30 years of experience in plasma physics, high-voltage systems, and technology innovation. Neal leads the team behind a novel lightning protection coating for wind turbine blades, developed through a U.S. Department of Energy-supported program.

Arctura Wind | www.arcturawind.com

Author: Neal E. Fine, PhD

Volume: 2025 September/October