How to Outsmart Mother Nature

Regardless of the season, the power industry is now facing greater challenges than ever to keep the lights on, as weather trends intensify. Extreme conditions such as prolonged drought, intense heat, high winds, sub-zero temperatures, large wildfires, heavy rains, and flooding can hinder energy production and elevate demand for electricity. This often results in increased brownouts, rolling blackouts, or even total power outages.

Renewable energy capacity is growing at a record pace. As the energy mix begins to tilt in favor of renewables, there is added urgency to ensure that these assets are able to withstand whatever extreme weather conditions Mother Nature dishes out. This is particularly challenging when these assets are in remote areas with rough terrain, far from maintenance staff, and exposed to the elements 24-7-365.

Utilities must leverage new technologies to help weather the storm so they can continue providing reliable power, and maintain grid stability throughout these events.

Continuous monitoring of solar PV panels during extreme events can alert operations teams of soiling conditions before the issue escalates.

Owners and operators of diverse renewable generation and energy storage assets often have limited access to production, environmental, maintenance, and performance data. This hinders their ability to optimize operations, especially when dealing with the stress of extreme conditions. Full data access, along with a holistic view of operations, will improve situational awareness, which helps ensure that power producers are better prepared for hard-to-predict events, especially as they navigate fleet transitions to greener energy.

Let’s take a closer look at how a portfolio of purpose-built renewable energy software and automation solutions can reduce complexity, and mitigate the potential negative impacts of dangerous weather events. Advanced value-driven solutions can help to proactively address impending issues, thereby reducing downtime, as well as the time and expense of servicing damaged equipment.

It starts with an integrated ecosystem

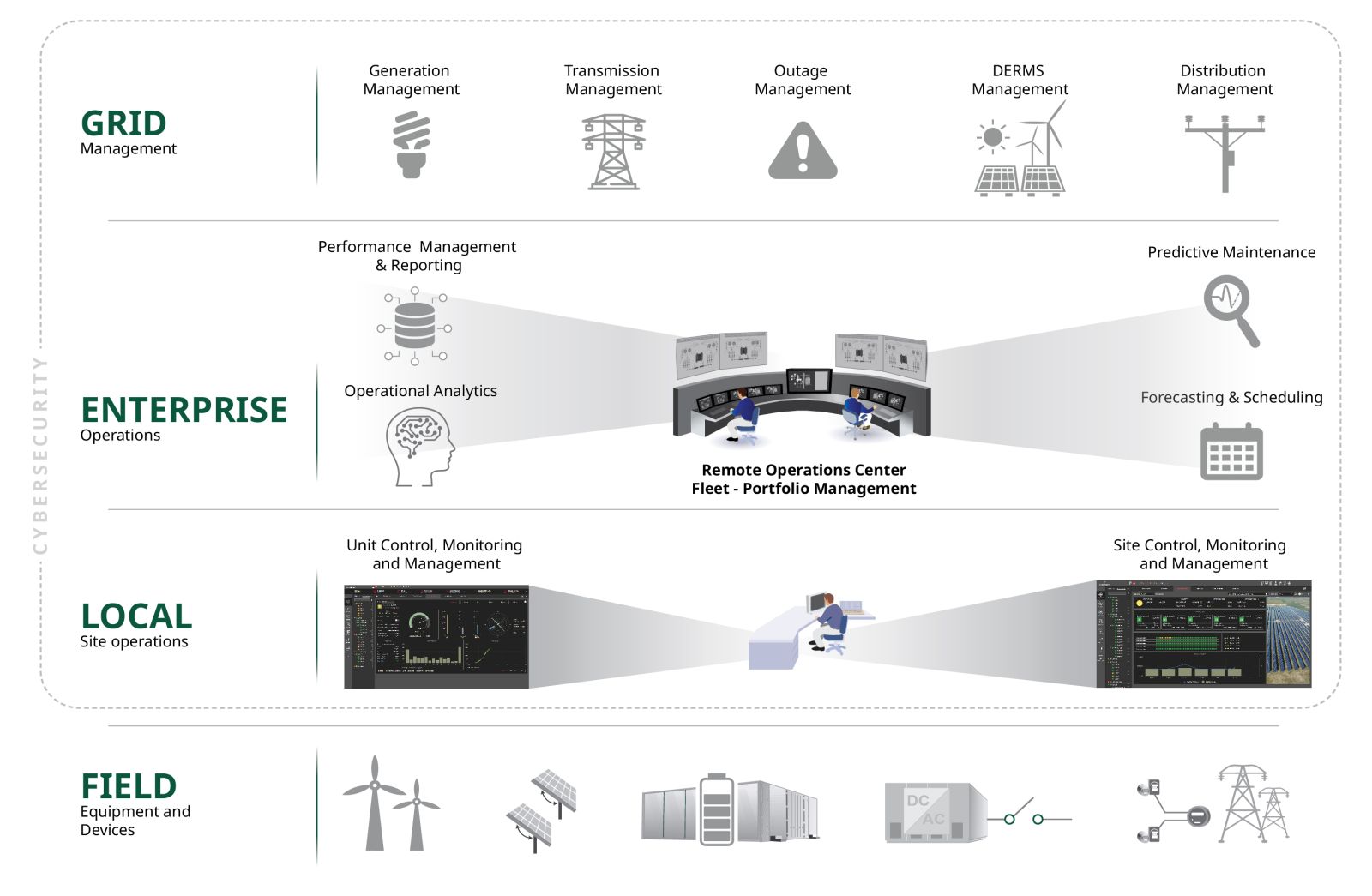

Utility-scale renewable energy and storage facilities generate massive amounts of data that exponentially grows as the portfolio expands. Unfortunately, this information is generated by numerous disparate systems, creating a siloed infrastructure that traps data locally. The result is increased complexity, especially for operators. An integrated, holistic automation ecosystem eliminates data silos and complexity by centralizing, contextualizing, and securely managing and communicating critical information across an organization — from the field devices, to local control, enterprise operations, and grid management systems. When the right personnel has full access to operational and financial data (when and where it is needed), analysis, trending, and forecasting are improved.

A fit-for-purpose renewable ecosystem provides a unified holistic view of unfiltered real-time operational data from the field, improving situational awareness so power producers are better prepared for hard-to-predict events.

Clear view from a single pane of glass

Renewable asset performance management and SCADA software (created specifically for green energy by industry pioneers) play a significant role in providing a unified view of unfiltered real time operational data — accessible anywhere, anytime. Implementing a scalable, asset performance management software solution that integrates data from any system, regardless of supplier or vintage, provides greater insights into equipment health. Full access to operations information puts the power of maintenance and optimization opportunities back into the hands of owners or operators, enabling quick and confident decision-making, which helps to avoid costly problems.

Predicting the unpredictable

Asset monitoring and health analysis deliver vital operating and maintenance information to key personnel so they can proactively manage assets, and improve reliability. For renewable assets with high-performing rotating equipment, such as wind turbines and hydro plants, condition monitoring systems with vibration analysis can help reduce costs and downtime by predicting impending issues earlier in the failure curve. With automatic and continuous monitoring of equipment operations, power producers can quickly and efficiently identify, diagnose, and resolve a problem before it escalates.

Artificial Intelligence turns data into actionable information

Data analytics is a key enabler of digital transformation, making it possible for renewable power generators to shift how they operate, becoming more efficient and agile and, consequently, more competitive. Advanced analytics can transition power producers from a reactive operations and maintenance approach, to a predictive or prognostic strategy. This actionable intelligence (built directly into the automation platform) unleashes efficiencies that improve operational situational awareness across a fleet of renewable assets. At the local renewable asset or site level, expert-system-based predictive analytics enable immediate resolution of short-term impending process or equipment anomalies, while augmenting centralized remote operation and M&D center capabilities for longer-term, strategic analysis.

Strategies in action

Wind turbines, notoriously located in remote, hard-to-service areas, are designed to withstand severe environments. As these turbines age, they become even more sensitive to stressful conditions. Owners and operators can help protect these assets during volatile weather seasons by implementing some of the solutions below.

- Advanced software with logic can automatically restart a wind turbine that has stopped operating due to stronger-than-usual gusts above the cut-out speed.

- Electric pitch and safety systems automatically and accurately adjust a wind turbine’s blade angle based on varying wind conditions, protecting the turbine from high wind speeds.

- Purpose-built condition monitoring for wind power can detect rotational imbalance caused by extreme heat exposure or icing on the blades, and trigger alerts to the right personnel for immediate action, before the issue escalates.

- Modern wind farm control strategies can detect when units are shutting down in response to temperature deviations and, in response, adjust the curtailment setpoints to the other units to maintain the Independent System Operator’s desired output.

Golden Valley Electric Association’s Eva Creek wind farm

Golden Valley Electric Association (GVEA) serves over 36,000 members in Interior Alaska who are on the front line of climate change. The GVEA recently completed a digital transformation project to improve the management of Eva Creek, Alaska’s largest wind farm. As part of the project, GVEA implemented software and automation technologies that provide more accurate equipment diagnostics and analytics. Increasing visibility into the wind farm’s operations has already had a positive impact, boosting the reliability of GVEA’s wind turbines, and contributing to a 65 percent reduction in operations and maintenance costs.

As reliance on renewable energy grows, it is vital to keep assets in operation, regardless of changing weather conditions or difficulties reaching equipment in remote locations. Harnessing and contextualizing data through an integrated, renewable-specific ecosystem of purpose-built software and technologies gives operators actionable intelligence to make swift decisions, helping to limit (or even prevent) damage and downtime. With these insights, power producers can build and scale sustainable operations with confidence, contributing to a more resilient, responsible, and smarter power grid.

Thomas Andersen is Vice President of Renewable Energy Technologies for Emerson, which provides software and technologies that increase reliability and annual energy production, while reducing operations and maintenance costs. Thomas began his career as an electrical technician with Mita-Teknik, a company known as a pioneer and leader in wind generation control. He has more than 30 years of renewable control and optimization experience with a keen focus on wind generation.

Emerson | www.emerson.com/ovation-green

Author: Thomas Andersen

Volume: 2023 May/June