Engineered Coatings for Roller Bearings Help Avoid Costly Repairs

Wind turbine mainshaft and gearbox bearings are subject to severe operating conditions. Volatile winds, extreme weather, and variable load scenarios can challenge the limits of bearing performance and reliability, particularly as turbines grow taller and more powerful. Bearing makers have responded with optimized designs for popular wind platforms; where added protection against mechanical wear is paramount, the industry offers engineered coatings that can stand up to the toughest environments on earth.

Wind turbine mainshaft and gearbox bearings are subject to severe operating conditions. Volatile winds, extreme weather, and variable load scenarios can challenge the limits of bearing performance and reliability, particularly as turbines grow taller and more powerful. Bearing makers have responded with optimized designs for popular wind platforms; where added protection against mechanical wear is paramount, the industry offers engineered coatings that can stand up to the toughest environments on earth.

Reducing Friction

Steel-to-steel contact is the trigger for virtually all bearing-related issues in wind turbines. This is largely due to the difficulty of maintaining an adequate lubrication film in mainshaft and gearbox bearings, even where operating conditions are ideal. The demands of wind energy production put incredible stresses on bearings that can degrade lubricating greases and oils-without proper maintenance, costly problems can develop.

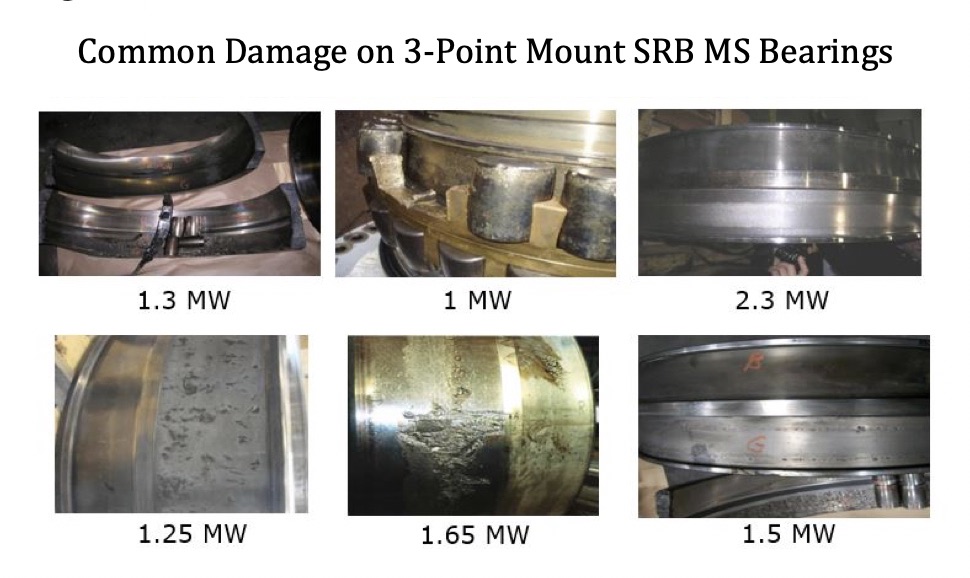

Many wind farm operators have felt the financial sting of a major corrective event when critical bearings fail to reach their target service life. More than a decade ago, as maintenance issues mounted, the wind industry grew aware of a wider trend: turbines designed for a 20-year life cycle often required bearing repair or replacement within just 10 years. What became evident is that modern multi-megawatt towers demanded more robust bearing solutions compared to older models. This led manufacturers to introduce new bearings built for the rigors of commercial-scale energy production. It also sent bearing makers down a path to improving performance in other ways, including the use of engineered coatings.

Becoming Less Steel-Like

One novel approach to coating technology traces back to the late 1990s, when scientists theorized that making the surface of bearing rolling elements less "steel-like" could effectively neutralize the adhesive wear, which is what happens when metal rollers and raceways come in contact (leading to fretting wear and/or corrosion damage to the raceways). Unfortunately, the techniques available at the time proved insufficient to achieve such a durable coating at economical cost. It would be several more years before a special plasma coating process, known as physical vapor deposition (PVD), would make such bearings commercially viable.

PVD is a vacuum deposition method used to produce microthin films on objects such as machine parts. PVD employs physical processes including heating, sputtering, or transfer by laser or electron beam to produce a vapor of material. This vapor is then deposited on the object that requires coating.

By 2010, the first wind bearings leveraging PVD coatings began to populate the market. These bearings made use of a plasma-based PVD sputtering method, whereby atoms are ejected by high-energy particles from a source material (the target), and transferred to a substrate (the bearing rollers).

How PVD Works

First, rollers are placed in a vacuum chamber and subjected to minute quantities of a special mixture of reactive gases, including Argon (Ar) and Acetylene (C2H2). In the presence of strong electric and magnetic fields, these gases react with the metallic target (commonly Tungsten carbide [WC]). The atoms from the target are then dislodged by high-energy collisions; plasma ions bombard the source material, causing portions of it to ionize and condense on the surface of the object.

PVD is so precise, it essentially allows coatings to be deposited atom by atom. This microstructure control makes it possible to engineer coatings that possess the exact performance characteristics desired in an application. Compared to conventional bath or spray coatings, PVD coatings are more uniform and much more durable; in oil-out conditions, bearings with PVD coatings have been observed to last approximately 10 times longer than bearings with uncoated rollers.

PVD is so precise, it essentially allows coatings to be deposited atom by atom. This microstructure control makes it possible to engineer coatings that possess the exact performance characteristics desired in an application. Compared to conventional bath or spray coatings, PVD coatings are more uniform and much more durable; in oil-out conditions, bearings with PVD coatings have been observed to last approximately 10 times longer than bearings with uncoated rollers.

When applied to bearing rollers, the PVD-coated surface acts as dissimilar material to the steel races, which minimizes friction. The coating is hard like a drill bit, yet slippery like a nonstick frying pan. This significantly reduces the likelihood of component scuffing, smearing, and wear as bearings rotate under extreme loads.

Years of Trouble-Free Service

PVD coatings are already proving effective in the field. Recently, in New Mexico, a 1.5 MW wind turbine using a mainshaft bearing with coated rollers was removed from service after seven years for re-powering. Bearing analysis showed little to no sign of adhesive wear on the raceways. In fact, the bearing was observed to be in "very good" condition for this stage of operation, despite the fact the bearing had not been relubricated in two years (in anticipation of the overhaul event). Furthermore, no evidence of progressive damage stages was found.

It was concluded, with a high degree of confidence, that the bearing would continue to operate into the 15- to 20-year time frame without issue. This was welcome news to the wind turbine owner because he was able to avoid the cost of a new mainshaft bearing entirely. Eliminating even one bearing replacement over the life of a turbine can save energy producers $100,000 or more, factoring in materials, labor, and logistics costs.

Innovation is Everywhere

Once restricted to a handful of laboratories, PVD methods have become widely available. Ongoing development has allowed the production of even more new coating types that can benefit machine components like wind bearings. In fact, wind turbine owners and builders have a growing inventory of coating options to consider when it comes to bearings, including coatings that offer tougher protection against corrosion, micropitting, and cracking.

Start a conversation with a trusted expert to learn more about engineered coatings-bearings that go the distance can have a big impact on productivity and profitability, from the smallest installations to the largest wind farms.

Vikram Bedekar is Materials Specialist, and Doug Lucas is Advanced Engineering Technologist for The Timken Company.Timken features a growing portfolio of engineered bearings and power transmission product brands.

The Timken Company |www.timken.com/wind-energy

Author: Vikram Bedekar and Doug Lucas

Volume: 2020 March/April