Elements of Surprise

In an industry where most critical infrastructure is left outdoors to face the elements day in and day out, mother nature's wrath is one of the many operational challenges that renewable companies must contend with. Whether you operate a solar farm or wind park, wind, lightning, ice, and hail can all wreak havoc on valuable assets and equipment. And while damage to a single turbine or solar array is costly, the prospect of losing potentially all of your generating capacity due to a failed collection or gen-tie transmission line could be even more catastrophic financially. While great steps have been taken to mitigate those risks to the generating assets themselves, more work can be done to harden the balance of plant infrastructure, specifically overhead collection and transmission interconnects.

Over the last two decades, a significant investment in renewable energy has been made across the country. A disproportionate amount of that development has occurred in the American heartland. Turbines have sprung up like wildflowers from the gulf coast of Texas to Minnesota and North Dakota. Unfortunately, this part of the country also experiences the most extreme weather imaginable. Severe thunderstorms and even tornados can be a weekly occurrence this time of year for operations in this part of the USA, which brings with it an increased level of damage risk. For those of you that don't live in Tornado alley, here is something to consider: all 50 states in the union have recorded tornado touch downs since 1950, even Alaska and Hawaii. No one is completely immune from this risk. So, while the threat may be more severe for some, every renewable operation should have a strategy in place to plan for and deal with failures and outages from extreme weather and anything else that mother nature can throw at you.

1) Owners that are in the process of building new sites or upgrading existing ones, would be advised to ensure your overhead line structures are designed to the wind and ice loading requirements of ASCE 74. This will result in stronger, more resilient structures in your balance of plant system. Many sites only design to the minimum NESC "safety" standards which are woefully inadequate as design criteria for extreme weather events.

2) No matter the material for the poles and towers, ensure they are specified to be designed to a "minimum" strength. Did you know wood poles are typically specified as a "mean" strength, while steel and concrete poles are typically specified to a "minimum" strength?

3) Make sure your purchase specifications are current and appropriate for the new project. A proper specification must identify the right materials for the probabilistic severe weather events expected (wind/ice). Your specifications should also address quality assurance protocols for how to properly design, fabricate, and install such infrastructure. Manufacturing defects in steel poles or towers, can make them susceptible to fatigue and failure during severe weather and high wind events. With the right quality assurance program, this risk can likely be avoided.

4) For sites already built and in service, a thorough asset management plan that involves a structural review of your infrastructure (not just electrical) is critical. If you know that your assets were under designed or built with little to no safety factors, modify your preventative maintenance strategy to take these weaknesses into account. Conduct more regular and detailed inspections to identify potential issues that may fail during a storm. If you have steel poles in your system, inspect them for corrosion issues or fabrication defects that might adversely affect the performance of your transmission line.

5) Your asset management strategy should also include a detailed storm response plan. Be ready to conduct drone inspections on the line following a storm to document even the smallest of defects that could prove significant to restoration efforts. Make sure that whoever is evaluating that data has a strong understanding of structural matters in addition to electrical matters. Consider having a safety stock of poles and structures on hand to replace failed components quickly, removing the risk of longer lead times and potential prices hikes for emergency product.

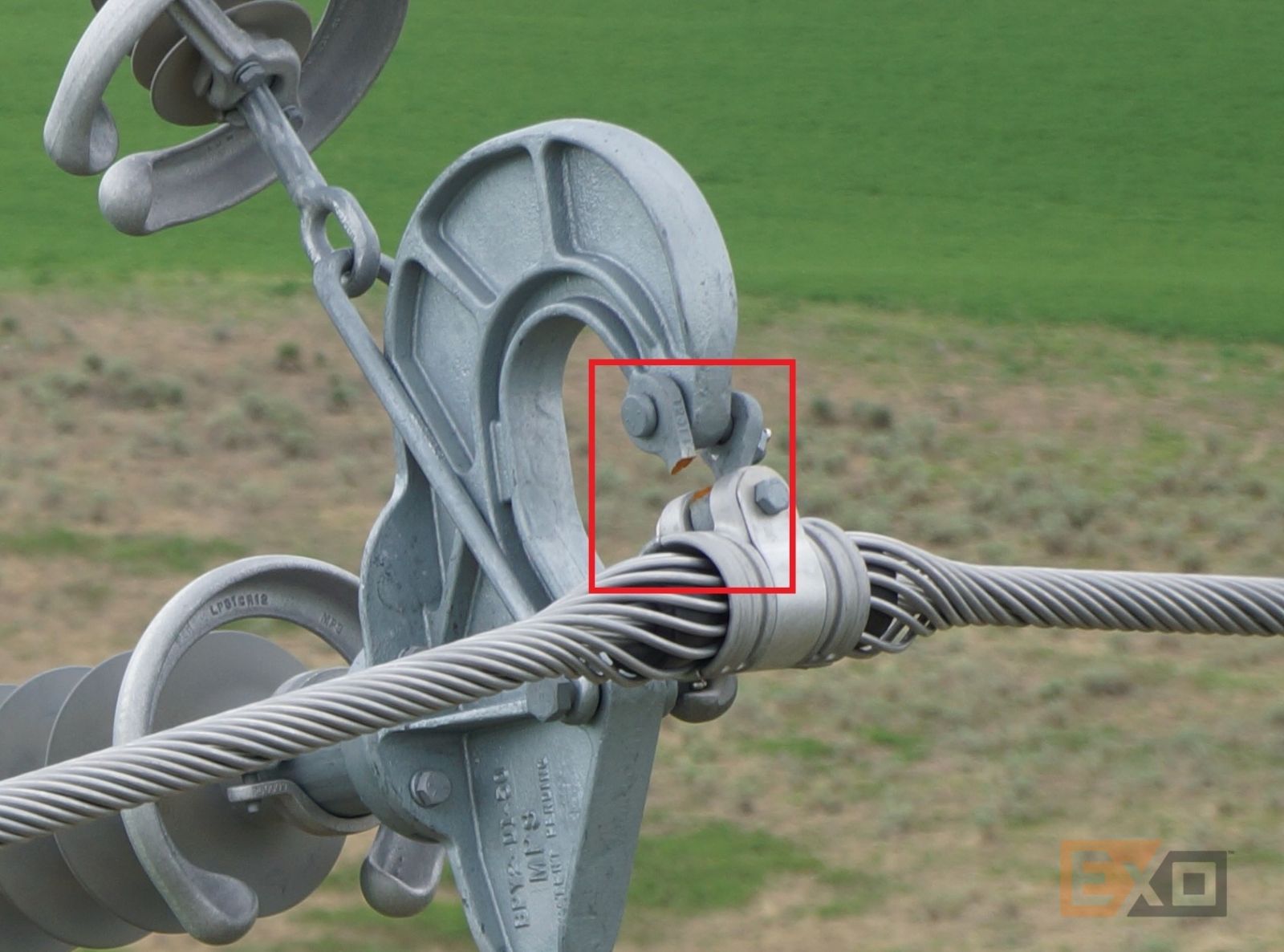

Unfortunately, there is nothing we can do to change the weather that impacts our renewable energy assets. However, there are plenty of proactive steps that owners, operators, and developers can take to mitigate these risks and improve the overall reliability and performance of our operations. When something as small as a single loose or missing cotter pin can take an entire site offline, it stands to reason that we should be taking greater care in the way we design, build, and maintain our balance of plant and transmission infrastructure so that our assets can stand up to the worst mother nature has to offer.

Grant Leaverton is Senior Account Manager at Exo, a U.S. based company that has over 100 years of experience of infrastructure inspection, evaluation, remediation, and manufacturing.

EXO | exoinc.com

Author: Grant Leaverton

Volume: 2020 May/June