Cables ‘Overlooked’ in Early Offshore Wind Cost Projections - Youwind

Faced with an ongoing trend of financial challenges linked to the installation and operation of subsea cables, offshore wind developers must start optimising their cable layouts at the earliest possible opportunity during the screening and development phases. This is the perspective of Youwind Renewables, a unique web-based solution for accelerating offshore wind development.

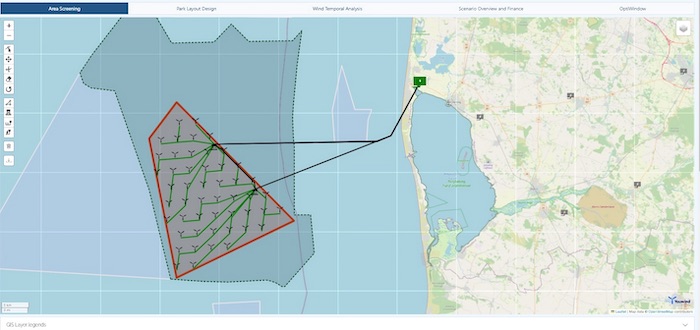

Youwind has, therefore, unveiled new cable visualisation functionality within its Pixel Park layout generation and micrositing tool. This will enable developers to quickly generate optimised inter-array and export cable layouts, simulate the impact of losses on future maintenance budgets, and build redundancy into wind farm designs.

Inter-array and export cables are widely acknowledged to be the most prominent point of failure for offshore wind farms in construction and operation – often contributing to significant unforeseen repair and replacement costs, alongside considerable loss of revenue when the ability of the wind farm to export power is affected.

Youwind’s data show that, for European wind farms, the failure probability is 0.0007 per kilometre of cable per year (Source: TenneT) – a figure that may seem small at face value but represents a significant threat to the profitability of any project without suitable redundancy measures in place.

With the Mean Time to Repair (MTTR) anywhere between 50 and 60 days for array and export cables, lost revenues can be very extensive – particularly if failures occur during periods of high winds and high electricity prices. Fixing the cables themselves represents a significant OPEX cost but losing generation for 50 days or more could result in financial losses of up to €100 million.

In general, wind farms are getting further and further away from shore, so cable length and the associated risk factors are becoming increasingly relevant concerns for the industry.

However, despite this considerable financial risk, in the early project phases developers often prioritise high CAPEX considerations such as foundation and turbine choice, focusing their layout optimisation efforts heavily on maximising yield and minimising foundation costs. This can leave array and export cables as an overlooked factor in financial performance projections.

“Cables represent a lower CAPEX cost as compared to other wind farm components, but, should they fail, have proven potential to lead to enormous OPEX costs and financial losses that have knock effects not only on the specific project, but also on the wider supply chain,” said Edvald Edvaldsson, CTO and Co-Founder, Youwind Renewables.

“With the benefit of this knowledge, the earlier developers start factoring these potential costs into financial projections and risk mitigation efforts, the better. Youwind is giving developers the tools to better understand the potential impact of cable failures and electrical losses from day one – from site screening to layout optimisation onwards.”

Youwind highlights that key risk factors to consider in layout optimisation include the length of cables, where they are connected and how many turbines are connected on each string. Furthermore, for array cables it is important to ensure the right cable voltage, cross section and material are chosen during optimisation, as this may have a big impact not only on the CAPEX and installation costs, but also on overall expected electrical losses – a key factor influencing P50 production estimates.

Youwind’s new cable visualisation functionality adds a powerful new dimension to its Pixel Park tool – an advanced web-based app that is already widely used by offshore wind developers to generate detailed wind farm layouts at high speed for any site worldwide, accounting for site-specific bathymetry and geography. Users of PixelPark are now able to generate and model the technical and financial performance of layouts including all major wind farm components – encompassing turbines, foundations, substations and cable routes – for both floating and fixed-bottom installations.

Importantly, they are also able to simulate and evaluate layouts that add crucial redundancy and resiliency to the wind farm design – such as multiple offshore substations connected by an interlink. Interlinks and ‘meshed grids’ have helped to mitigate the impact of recent cable failures on European offshore wind farms and will play a prominent role as development zones become more populated in the coming years.

Youwind | https://youwindrenewables.com/