ADLS 101: Choosing an Aircraft Detection Lighting System for your wind farm

An Aircraft Detection Lighting System (ADLS) is a sensor-based system that monitors the airspace around a wind farm, activating the obstruction lights only when aircraft are within a defined buffer zone. ADLS technology originated from the 'Dark Sky' movement in the 1950's when astronomers were concerned that nocturnal skyglow from urban areas was blotting out stars. In 1988, the International Dark-Sky Association focused on 'excessive use of artificial light' in remote areas. The use of ADLS today at windfarms is primarily being driven by nearby residents objecting to the constant flashing of the lights at night.

In 2011, the U.S. Federal Aviation Administration (FAA) started researching radar-activated obstruction lighting technologies, and issued performance standards in an Advisory Circular (AC 70/7460-1M, Chapter 14, "Aircraft Detection Lighting Systems"). Other countries including Canada, Australia, and Germany now have similar standards. Several US states, including North and South Dakota, have now mandated ADLS for new and existing windfarms. Other states and some local jurisdictions are also now requiring or working on regulations for ADLS.

How ADLS Works

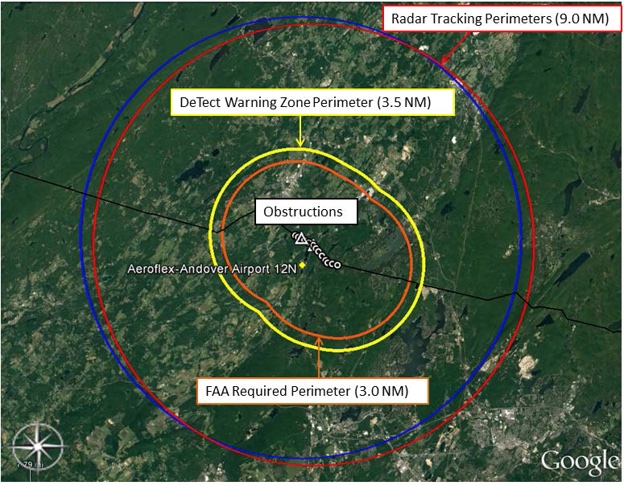

In operation, an ADLS continually monitors the airspace around and above the wind farm for aircraft. When an aircraft is detected crossing a preset boundary, the system turns on the obstruction lights, keeping them on until the aircraft clears the control area (at right). The FAA activation zone includes a 3-nautical-mile buffer around each obstruction and a 1000-feet buffer above the tallest obstruction. Most ADLS systems are tower or turbine-mounted within the wind farm to provide full, unobstructed 360-degree monitoring of the airspace. For large wind farms or sites with complex terrain, multiple radar units may be required for full coverage.

In operation, an ADLS continually monitors the airspace around and above the wind farm for aircraft. When an aircraft is detected crossing a preset boundary, the system turns on the obstruction lights, keeping them on until the aircraft clears the control area (at right). The FAA activation zone includes a 3-nautical-mile buffer around each obstruction and a 1000-feet buffer above the tallest obstruction. Most ADLS systems are tower or turbine-mounted within the wind farm to provide full, unobstructed 360-degree monitoring of the airspace. For large wind farms or sites with complex terrain, multiple radar units may be required for full coverage.

Implementing an ADLS

An ADLS is n ot just a radar - it is comprised of the radar(s), the obstruction lights and necessary infrastructure. The radar includes the processors, operating software, data system, radar towers, backup power, and SCADA network interface (at left). Radar tower height is determined by line-of-sight modeling to provide full coverage. The obstruction lights also must be 'ADLS compatible' and connected to the wind farm fiber optic network. Each radar unit requires power and fiber from the closest turbine to the radar for connection to the wind farm network. Advanced ADLS systems allow for sensitive processors and electronics to be installed in the windfarm operations building, with only the radar sensor installed at the tower site which reduces O&M costs.

ot just a radar - it is comprised of the radar(s), the obstruction lights and necessary infrastructure. The radar includes the processors, operating software, data system, radar towers, backup power, and SCADA network interface (at left). Radar tower height is determined by line-of-sight modeling to provide full coverage. The obstruction lights also must be 'ADLS compatible' and connected to the wind farm fiber optic network. Each radar unit requires power and fiber from the closest turbine to the radar for connection to the wind farm network. Advanced ADLS systems allow for sensitive processors and electronics to be installed in the windfarm operations building, with only the radar sensor installed at the tower site which reduces O&M costs.

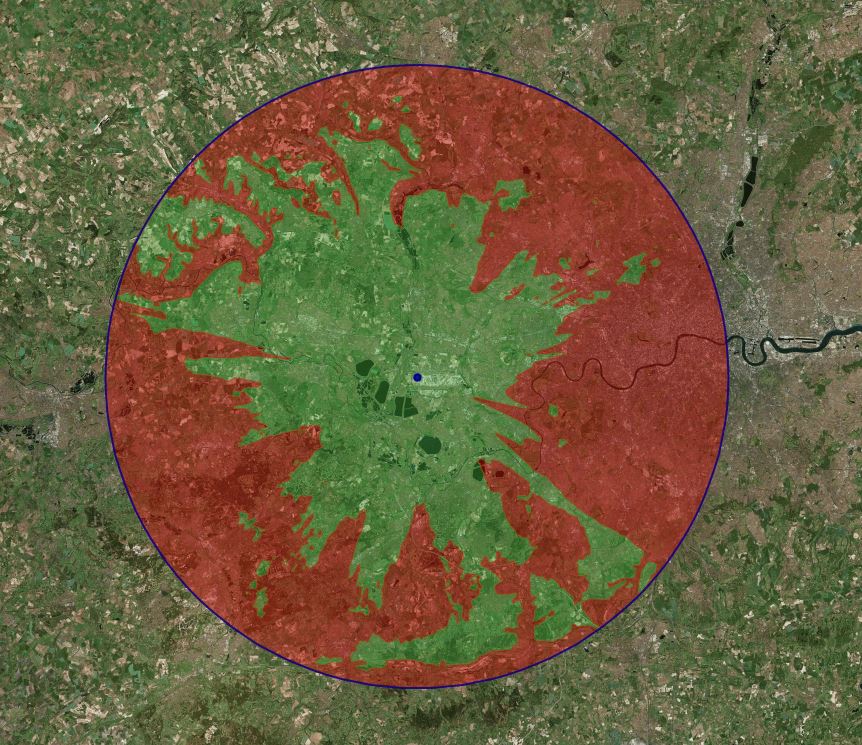

To determine if a wind farm is a candidate for an ADLS, GIS and viewshed analysis of the site is conducted by the ADLS supplier to define the number of radar units required for complete airspace coverage and locations for the radar(s). Special siting considerations include radar beam blockage by terrain, structures and other obstacles (e.g., tree lines), lattice vs monopole towers (raptor issues), onshore vs offshore installation, light compatibility, availability of power and fiber to the radar, local aircraft activity levels, and other factors (land access, cultural/natural resource areas). The viewsheds are analyzed at various aircraft altitudes to ensure that aircraft are fully 'visible' to the radar (below).

Once the final turbine and radar locations are set, the owner files the ADLS Obstruction Lighting Plan with the FAA. The package includes the location of all turbines and radars and viewshed maps at various altitudes ranging from 200-1000 feet. Most ADLS vendors prepare the FAA filing package as part of their proposal at no cost.

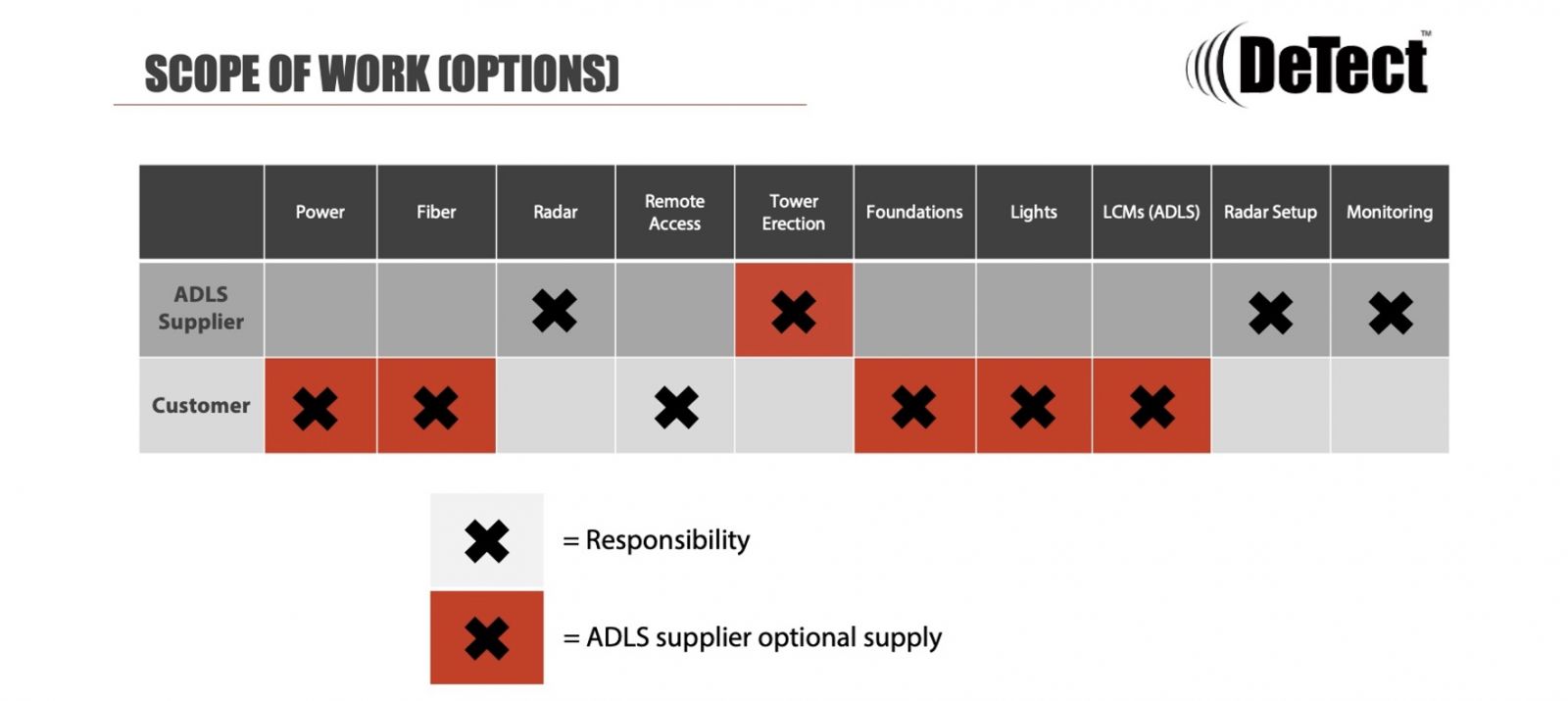

At this point, the infrastructure and construction requirements and costs can be determined, including costs for running power and fiber to the radars, tower foundations, network interfacing and cyber security, and obstruction lighting connection to the windfarm network. For older windfarms, the lights may not be compatible or upgradable and may need to be replaced. Scope of work assignments can vary from the ADLS vendor supplying only the ADLS radar, and related services with a general contractor performing the construction-related tasks to full turnkey delivery (below).

Project Schedule

The typical ADLS project takes 8-10 months from system manufacture to installation, commissioning, and turnover. Due to the current microchip supply shortage, some component lead times are longer, so schedules are running 10-12 months for 2022 COD projects. After installation, start-up of the ADLS is fairly short with the system operational within a week. It should be noted, however, that optimization of the lights OFF/ON periods to the lowest safe level can take up to 60 days as the data from the radar undergoes QA/QC and filters are developed for non-aircraft targets (e.g., birds).

Long-term O&M

Long-term O&M

ADLS radar technology is based on existing aircraft radars and is highly reliable with operational rates of over 98 percent. A key safety system built into most ADLS is that the radar does not turn the obstruction lights on, but only sends a lights OFF command when all safety and diagnostic heartbeats are clear of failure and no aircraft are present within the buffer zone. This failsafe design ensures that if the ADLS equipment fails or loses network connectivity, the override signal is lost and the lights automatically are ON.

O&M costs and level of effort is low, and most ADLS suppliers offer extended warranty/service plans that cover all maintenance and repairs for the life of the project. This includes 24-7 monitoring of the system and daily reporting of the lights ON and OFF times, including exceptions such as system failures and weather.

Lessons Learned

ADLS today is a proven, reliable and widely deployed technology, but there have been a lot of lessons learned. A key lesson learned from dozens of ADLS installations over the past few years is that developers need to be careful how they present the ADLS to public stakeholders; while most projects are seeing lights OFF periods of more than 95 percent, there are sites where aircraft activity is high that increases lights ON periods. Additionally, during spring and fall bird migration periods, lights ON times may increase as some bird activity can be seen by the radar as potential aircraft.

Gary Andrews is President & CEO, and Jesse Lewis is Senior Vice President, ADLS at DeTect, Inc., which specializes in advanced radar and other sensor technologies. DeTect deployed the first radar-activated wind farm turbine obstruction lighting system in the US.

DeTect, Inc. | detect-inc.com

Author: Gary Andrews and Jesse Lewis

Volume: 2021 September/October