The Green Hydrogen Conundrum

When the White House announced $7 billion in funding for seven green hydrogen hubs, it signaled the start of a new era in clean fuel creation and consumption. Green hydrogen is envisioned as a major source of fuel for heavy industry, shipping, aviation, and many other industrial applications, and is an important factor in lowering carbon emissions and achieving the environmental goals established by the Paris Accords. The White House described green hydrogen as an essential part of a policy for building a “strong clean energy economy that strengthens energy security, bolsters domestic manufacturing, creates healthier communities, and delivers new jobs and economic opportunities across the nation.”

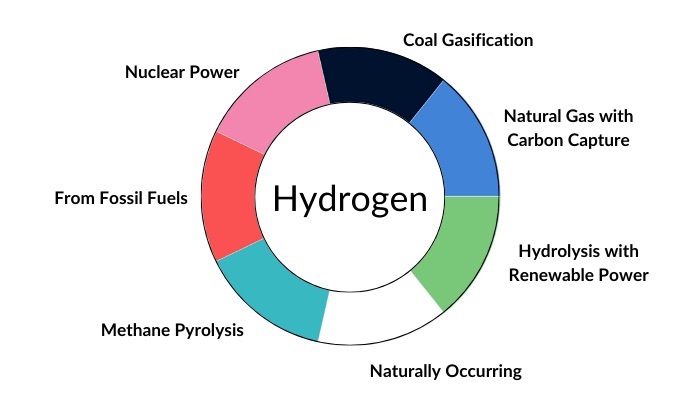

Hydrogen—already a critical component in chemical manufacturing—presents a conundrum for use as a source of clean energy. Traditional gray hydrogen processes generate high carbon emissions as a byproduct, running counter to the nation’s clean energy ambitions. In contrast, green hydrogen production is carbon neutral, requiring processes that are far more complex and expensive. Therefore, one major challenge to realizing the White House’s vision will be innovations that enable efficient and economically viable production of green hydrogen at a massive scale.

Scale-up and reliability

Because of commitments made by some carbon-intensive industries to reduce greenhouse gas output by switching to clean alternative fuels like green hydrogen, production will need to quickly scale to meet demand while simultaneously figuring out ways to generate efficiencies in production that will help drive prices down. For green hydrogen, these efficiencies demand more than merely tweaking current production methods, and will only come from new thinking that leads to new processes and designs for electrolyzing water into its constituent parts.

Innovation and technology breakthroughs are key to reducing both the overall cost of green hydrogen production. That means every OEM contributing to build the stacks and plants needed to construct tomorrow’s green hydrogen hubs will be expected to do more than fill orders with existing product solutions; they will be collaborators in the ideation, engineering, designing, testing, refinement, and implementation of systems and processes yet to be conceived. Rather than a haven for convention, green hydrogen is a greenfield opportunity for bold thinkers eager to accept the challenge. There is too much at stake, and the timelines are too short.

Race to innovation

Regarding the production of porous transport layers for water electrolyzers over the last two decades, the markets and volumes were limited. That is quickly changing. Now, with significant new investments combined with heightened interest and urgency around meeting decarbonization mandates, there is a lot of demand for innovation in the industry. Innovators are racing to establish stable, efficient, and scalable systems and processes for the production and consumption of green hydrogen.

The good news is that there is an eager market. Hydrogen consumer industries already exist — these will readily shift from gray hydrogen to green when there are reliable sources at competitive prices. Industries like shipping have already committed to transitioning from traditional fossil fuels to green hydrogen, setting aggressive goals for decarbonization that will accelerate demand and grow the global market from approximately $185 billion today, to what is predicted to become a $1.4 trillion market by 2050, as suppliers work to increase production to satisfy expected demand for 600 million tons of the fuel.

Recent analysis shows that, as the global shipping industry works toward achieving a 20 percent reduction in carbon emissions by 2030, new vessels designed to run on hydrogen are already being built and entering service. Yet, as the number of ships powered by hydrogen and other carbon-neutral fuels enter fleets, they will “[face] headwinds if we can’t compete with sectors like aviation for the same fuels for decarbonization or with chemical industries.”

A challenge and opportunity

That presents both a tremendous challenge and opportunity for those of us already in the green hydrogen market as producers of fuel and suppliers of the systems and technologies needed for production. We are not burdened by the inertia that comes from two centuries of tradition and standards that do not apply to a new era. Instead, we must use that flexibility to pivot quickly and create new product designs and specifications as the lessons we learn from field installations unfold, working to ensure that every improvement advances efficiency and durability. OEMs can—and must—seize the moment and collaborate to quickly build our industry into what it can become, welcoming new ideas even as we reimagine our own contributions to the future of energy production.

If producing green hydrogen was easy, we’d already be doing it and living in a much different world. We can get there by drawing on our legacy of experience to make certain our innovations are reliable, scalable, and efficient enough to meet the demands that will drive our market forward. And so, even as the government has kick-started that needed scale-up with $7 billion in funding to accelerate progress in the short term, we can’t ignore the long-term realities that, for green hydrogen to earn wide adoption, the economics must make sense. Therefore, our focus every step of the way must be on quality and precision as we engineer the solutions that will become tomorrow’s green hydrogen plants.

Matt Behrns is the Vice President and General Manager for the Clean Energy business unit and marketing function at Mott Corporation, with global responsibility. He oversees the company’s ongoing growth focused on new product development and expanding into high-growth markets. Mott Corporation is a technology-driven, precision filtration company relied on by technical and performance brands worldwide across four core markets: Medicine, Computing Power, Clean Energy, and Space Exploration.

Matt Behrns is the Vice President and General Manager for the Clean Energy business unit and marketing function at Mott Corporation, with global responsibility. He oversees the company’s ongoing growth focused on new product development and expanding into high-growth markets. Mott Corporation is a technology-driven, precision filtration company relied on by technical and performance brands worldwide across four core markets: Medicine, Computing Power, Clean Energy, and Space Exploration.

Mott Corporation | mottcorp.com

Author: Matt Behrns

Volume: 2024 January/February