The 4Ps of Solar Tracker Software

To steer success in utility-scale solar, produce, predict, perform, and protect can generate a roadmap to help developers and asset owners source the right single-axis tracker for their project, for peak performance in the toughest weather.

As structural and mechanical advances let manufacturers scale and keep costs down, the next frontier involves performance monitoring and controls software. Owners and developers are constantly exploring opportunities to:

• Increase energy yield, and reduce downtime

- Minimize weather-related losses

- Optimize tracker performance, and boost project returns

It’s critical for decision-makers assessing solar tracker options to evaluate how control software impacts a project’s long-term performance, particularly during extreme weather events. The 4Ps of tracker success help to ensure optimal reliability, system yield, and financial returns.

Intelligent tracker software is the key. Today’s trackers are far more advanced than their predecessors, capable of operating on sites with high wind speeds and snow loads. But the technology is just beginning to reach its maximum potential.

Extreme weather calls for smart systems

Extreme weather calls for smart systems

When assessing control systems for tracker technologies, look for machine learning capabilities, real-time data, and weather monitoring systems that proactively track, alert, stow, or troubleshoot your SAT’s production. Some important features to seek include:

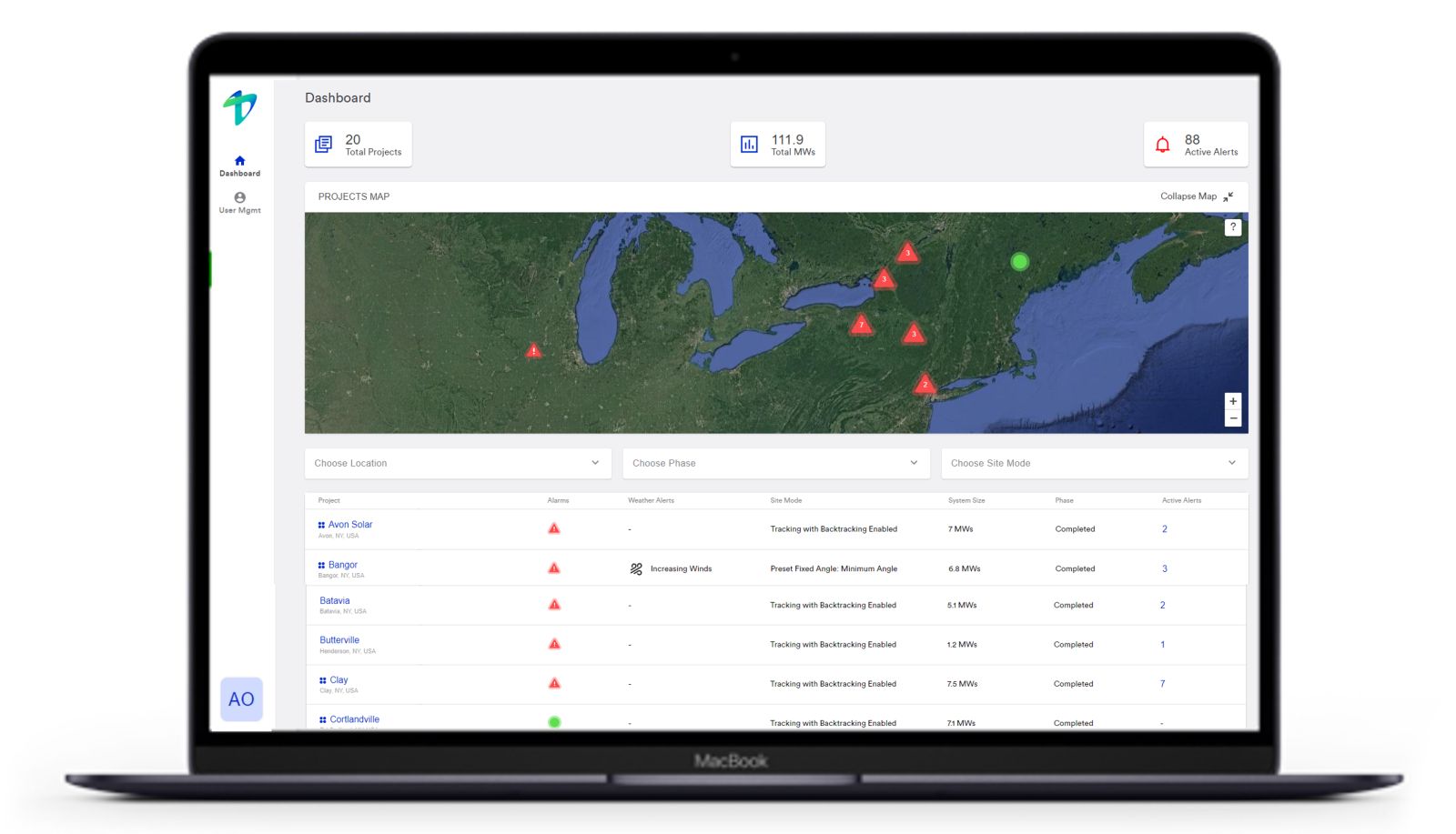

- Real-time data and dashboard with email and SMS notifications to guide predictive and corrective maintenance, such as project mapping and row-level monitoring.

- A smart weather API and on-site sensors that forecast and monitor snow, wind, and flood to alert you when trackers should be stowed before bad weather can damage systems. A stow angle optimized at 60 degrees helps distribute and stabilize loads across rows.

- Remote software updates and a real-time cellular connection to allow easy enhancements and remote troubleshooting, keeping systems up-to-date while reducing truck rolls on site.

- Proprietary AI cloud systems that feature powerful machine learning to run predictive analytics, reduce downtime, and maximize energy yield.

Produce more energy

Using adaptive machine learning and historical data, tracker software can project where the sun will be at different times of the day, then optimize module positions to gain maximum energy yield. Advanced backtracking algorithms minimize row-to-row shading. Configuration parameters and sun angles help determine how a row should be positioned to avoid shading its neighbor, while also considering the terrain of rows directly to the east and west.

Predict performance

Cloud-based data supports predictive analytics and maintenance to address issues before they disrupt production — and revenue. Machine learning algorithms can detect when a row is not tracking properly so you can fix issues before they impact performance. This saves on cost, reduces downtime, and mitigates worst-case scenarios. User-friendly dashboards allow you to always know how your site is performing, whether across all projects, or drilling down to the row level to understand issues.

To contend with an increasing number of extreme weather events, smart systems are integrated with weather APIs to monitor local weather forecasts. If wind variables exceed a predetermined threshold, equipment can be stowed before the storm hits. The modules then remain stowed until all weather alerts are cleared and sensors report consistently safe conditions once again.

Protect from weather events

Extreme weather can damage assets, increasing remedial costs, jeopardizing operations, and driving up O&M budgets. But tracker technology can mitigate weather-related risks. A feature called smart stow can use weather APIs to react to alerts from on-site weather stations about when incoming storms pose a threat. The system can stow modules proactively to protect against the potentially damaging effects of high winds and deep snow.

Some intelligent systems include distributed row box intelligence that allows the rows to stop tracking, and get to a safe position if motor currents exceed thresholds. Distributed intelligence also can prompt safe stow when batteries are low, or if the row boxes cannot communicate with a network controller. After local issues are resolved, the rows automatically resume operations.

Perform easier O&M

Some tracker software packages offer remote access. Gone are the days when a bug in the system meant rolling a truck to the site to find out what went wrong. Paired with historical data, real-time monitoring down to the row level allows for remote troubleshooting and quick diagnosis. Systems with dynamic administrative panels let users see inside the project site to conduct data analysis to identify the issue. Other value-added features include zone controls that allow moving portions of a site for routine maintenance like mowing and washing, without compromising optimum power generation.

Asset operators often must deal with rows that aren’t tracking properly. Look for smart systems that create tracking projections for each row, and send notifications when a row fails to meet its projection. This lets O&M personnel address issues quickly to maintain optimal production.

Intelligent tracker software will play a pivotal role in giving projects a competitive edge. Control systems with advanced AI and machine learning features will minimize weather-related risks like hail and high winds, helping the solar industry scale new heights in energy production

Chase Anderson is Director of Product Development at Terrasmart, where he has been a key contributor across engineering, estimating, and R&D departments since he joined the company in 2012. He has been pivotal in advancing research and testing on wind and snow load analysis, and continues to drive innovation as lead design engineer for the company’s SAT and fixed-tilt racking solutions. Terrasmart provides solar racking technologies, eBOS products, installation services, and project optimization software, with over 20 GWs of solar deployed across 4900 PV systems.

Terrasmart | www.terrasmart.com

Author: Chase Anderson

Volume: 2023 May/June

.png?r=9923)