Solar in High Winds: Ground mount solar designed for extreme hurricanes in the Caribbean

High-density, low-profile, aerodynamic racking solutions are becoming a popular solution for sites with extreme winds, particularly in land-constrained Caribbean.

Basic design of the system can be observed above. Rebar is installed in the ground with a top plate crimped on top. Modules are placed on the top plate with module clips screwed from above. The module frame becomes part of the substructure to minimize material usage. Standard design is 0.8 meters at lowest point and 1 meter at tallest. Courtesy of Meralli Projects

A case can easily be made for utilizing high-density, low profile ground mount racking solutions the Caribbean. This is based on the following parameters:

- High Wind Design of up to 180 mph (based on ASCE 7 – 10) with the most cost-effective foundations

- Long-term Insurability with high-wind design for hurricanes

- High-Density Efficient Land Usage

- Suitability for large variety of Soil Types

- 78 percent Reduction in Raw Material Usage

- Compact Shipping simplifies import process

- Simplicity of Install means local labor force can be utilized

- Reduced EPC Costs leads to reduced LCOE versus trackers and Fixed Tilt Systems

High Wind Design – The racking solution has undergone extensive wind tunnel tests. It’s extremely aerodynamic, coming up to about waist level, which allows for it to achieve 180 mph winds with standard clamping solution (ASCE 7 – 10). Since it’s in an East West 8-degree tilt and low above-ground, there is minimal uplift to withstand much higher winds. There is already a project on the ground installed in the cyclone region of West Australia. There is an additional upcoming 8 MW project in the Caribbean with construction scheduled for this year.

High-Density, Land Use Efficiency – The solution can produce about 225 percent more MWh/acre than fixed tilt and tracker systems (according to DNV GL’s bankability report). As an example, a site in the central Caribbean (Dominican Republic) has a yield of ~1,532 kWh/kWp/year, which leads to 1,194 MWh/acre/year due to the efficient land use of ~0.78 MW DC/acre. For an island like Barbados, the solution is ~19 percent better with 1,819 kWh/kWp/year, 1,419 MWh/acre/year.

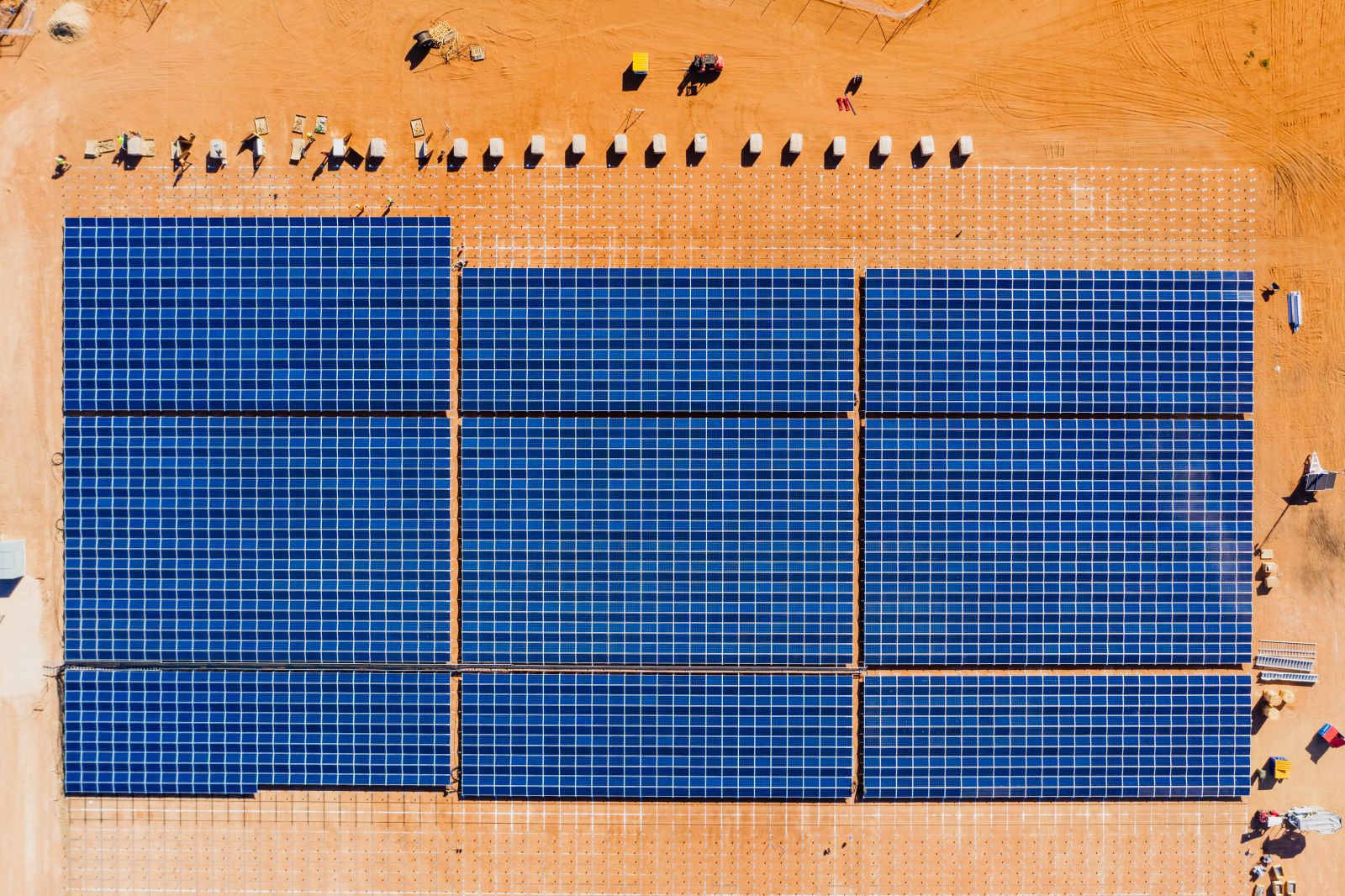

High-density and efficient land use can be observed above. Minimal materials with rebar bars that have been installed can also be seen to the right. Courtesy of Meralli Projects

High-density and efficient land use can be observed from birds eye view. Site as shown is under construction. Courtesy of Meralli Projects

Location and Sandy Soils – The solution becomes even more attractive the closer it is to the equator, making the Caribbean an ideal location. Additionally, the solution has a well-suited helical screw (anchor rod) that can be used in soft, sandy soils and only requires ~ 0.5-0.6 meter (1.64 – 1.96 ft.) foundation depth. A shallow foundation can prove useful to avoid hitting volcanic rock and removing the need for expensive pre-drilling.

Minimal Materials – When compared to a conventional fixed tilt or tracker system, the solution uses 78-95 percent less steel. Conventional systems require I-Beam foundations of 10-15+ meters. Assuming 540-watt modules, 32x12 module block, 0.5 meter embedment, and 150 mm anchor rods, you’re are looking at 8,600 kg of materials per MW DC. Note, if the site is slopped or has some uneven terrain, the system may require additional material. Rods are inserted directly into the ground, removing the need for any concrete or other materials. The DC system, including the cables, is above ground so there’s no DC trenching.

.jpg)

Under array with ample room for O&M service and air flow. Robotic mowing is available for sites requiring vegetation. Courtesy of Meralli Projects

Compact Shipping – 40 ft. containers can handle up to 20-25T (country specific), meaning ~2.6 MW DC of racking can be carried in each container. This makes shipping to islands extremely efficient, which can be particularly attractive to islands with limited port sizes. This helps address current port congestion and shipping costs.

Simplicity of Install – All tools required for the system are hand held. Since there is no heavy machinery, sourcing equipment is simplified. All tools are commercially produced, easily available, and simple to use. The simple design also allows for installation by unskilled labor. With 540-watt modules, a total of ~500 man-hours per MW is required for the DC installation, which is ~50 percent less vs trackers. Around 420 of those hours are related to DC installation; ~70 is related to waste handling, inverters, and site restoration. Approximately 60 percent of those 500 hours is done by unskilled labor, helping to simplify sourcing a workforce on a remote island. This particular aspect made the solution attractive for remote mining sites in Australia.

Module installation with wiring performed as you install the modules. Courtesy of Meralli Projects

Bankability – The solution has been deployed globally on over 400 MW, making it one of the most used high-density ground mount solutions. Extensive Bankability report from DNV GL, wind tunnel tests by the IFI engineering firm, and over 2.8 GW of substructure supplied by racking company globally are all contributing to the bankability of the solution.

EPC Costs – Overall, there is a ~30-40 percent reduction in EPC costs (excluding interconnect). EPC quotes can be provided on a project specific basis upon request.

In summary, the solution is extremely well adapted and designed for the Caribbean’s extreme high wind environment. The solution’s high-density, reduction in materials, and simplicity streamlines the whole installation process by drastically reducing construction effort, logistics, and labor sourcing.

Matthew Lusk is Vice President of Business Development for Jurchen Technology for the USA and Caribbean. He brings nearly a decade of experience in the solar industry as a leader in the advocacy for solar and energy storage. He is raising awareness of how high-density solar solutions can play an integral role in the world’s transition to clean energy by solving issues of land availability, labor force sourcing, shallow foundations, extreme wind suitability, and ease of access to inexpensive solar globally.

Jurchen Technology | www.jurchen-technology.com

Author: Matthew Lusk

Volume: 2022 May/June

.png?r=7229)