Rooftop PV Project Permitting

The solar PV permitting process has been involved in an evolutionary struggle: in the early years, from AHJ’s having essentially little or no understanding of PV installations, to now with many AHJ’s developing a full understanding of the details and all of the nuances required to properly evaluate and permit projects. One of the unique aspects of rooftop installations is the guaranteed integration of both verification of building structural adequacy and electrical design upgrades. Recent ASCE code updates have also adopted the SEAOC method of calculating under module lift forces.

As more PV and ESS projects have come through their doors, AHJ’s have increased their understanding of PV system components, fastening methods, and required electrical upgrades (based on the uptick in PV rooftop applications). Incidentally, the review time frames required to permit a PV or PV with ESS project have grown to match that of standard construction projects.

Anything that can be done to shorten the overall permitting time period should be done.

NREL has developed software, “SolarAPP +”, to help AHJ’s more quickly evaluate and permit these projects. Amazingly, in the most populous solar state of California, only 25 out of a possible 530 AHJ’s have signed on to use this standardized permitting platform. Across the rest of the US, virtually no AHJ’s have answered the call to standardize and smooth the way for solar project permitting. In the south and central USA, and along the eastern seaboard, only one AHJ in Virginia – Harrisonburg – has joined in support of quick turn solar permitting with their adoption of the SolarAPP+ system.

Outside of SolarAPP+ permit document reviews, the typical permit review process can take upwards of weeks, or even longer, to get a permit approval on a perfect set of plans and structural report.

While many US based installers have in-house staff to prepare their own plan sets, a large percentage of the PV plan preparation has shifted overseas (most notably, to India) owing to a combination of lower wage rates and, more importantly, the half day time shift from mainland USA. That time shift allows a project submitted today to receive simple residential plan sets the following morning.

Along with that relatively fast plan set preparation, installers seek additional services to be returned on a short time basis. Specifically, part of the plan submission requires a Professional Engineer (PE) prepared and sealed rooftop structural evaluation and report, along with PE signed/sealed electrical calculations. Interestingly enough, some engineering firms providing rooftop structural engineering evaluations use incorrect methods because they are easy to prepare, not because the results are correct. In areas with little or no snow, using the IBC 5 percent or CBC 5 percent method – essentially weighing the roof in its present condition, and comparing that weight to the roof and solar weight combined – can be a correct evaluation method. Areas with as little as 5 psf snow loading require a different analysis method based upon the evaluation of existing roof framing or truss systems.

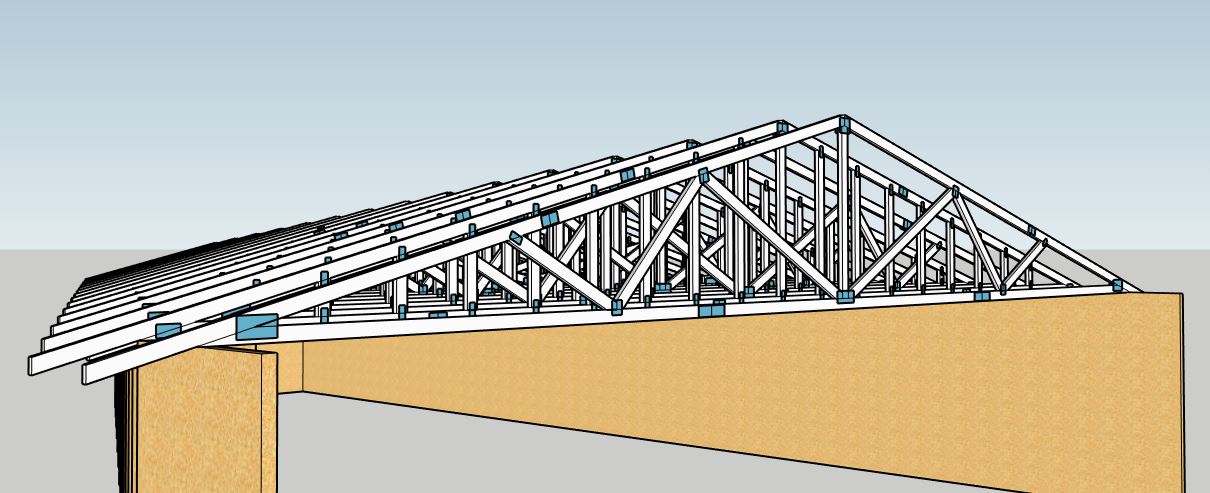

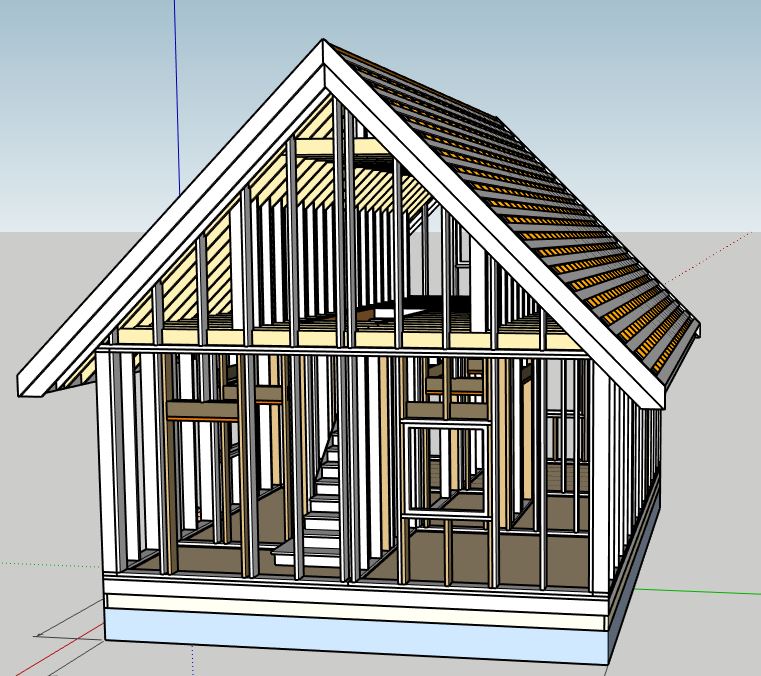

Wind, snow, and dead load combinations show that substantial forces coming down to the roof surface from PV module supports can be placed on individual roof framing members or trusses by concentrating the loads onto PV supports, while roof framing between module supports have their distributed loads reduced substantially. That said, staggered arrangements of PV supports redistributes loading on structural members, transforming evenly distributed environmental loads into moderately high point loads, which can impact individual structural members. The impacted roof framing supports may be subjected to significant point loading forces. Members supporting these point load forces should be individually analyzed. Standard roof framing systems require individual framing member structural analyses, while roof trusses require preparation of a Finite Element Analysis (FEA) demonstrating the entire truss system’s ability to adequately support the new concentrated loads.

Wind, snow, and dead load combinations show that substantial forces coming down to the roof surface from PV module supports can be placed on individual roof framing members or trusses by concentrating the loads onto PV supports, while roof framing between module supports have their distributed loads reduced substantially. That said, staggered arrangements of PV supports redistributes loading on structural members, transforming evenly distributed environmental loads into moderately high point loads, which can impact individual structural members. The impacted roof framing supports may be subjected to significant point loading forces. Members supporting these point load forces should be individually analyzed. Standard roof framing systems require individual framing member structural analyses, while roof trusses require preparation of a Finite Element Analysis (FEA) demonstrating the entire truss system’s ability to adequately support the new concentrated loads.

While it is possible for such structural analyses to be done by hand using custom made, proprietary spreadsheets, such analyses can be costly and time consuming, taking over a day, and costing $125 to $250 per single family roof structural analysis along with plan review/sign/seal. Many AHJ’s electrical plans also require an engineer’s approval, which can cost an additional $150 to $250 complete.

Alternate, far less expensive and faster services exist which, for a single low fee, allow PV Designers to enter basic existing building, framing, and electrical information, along with proposed PV design information; within an instant, a structural analysis report is generated, along with any recommended structural upgrades and electrical calculations.

One interesting feature of such services is that these reports can be used by the PV Designer as a design and cost reducing tool by trying different PV module arrangements to minimize or eliminate new structural support requirements, simply by moving PV modules to different parts of a roof’s span.

Once those reports are created, they are followed by a PE’s review of the project’s photographs and drawings demonstrating fealty between the input data, actual field conditions, and the PV design. The customer can expect a return of a finished structural report and reviewed/stamped/sealed/eSigned structural and electrical plans, in as little as 3 hours.

Complete PE services can be provided directly by entities offering this service, or by third party engineers using these same software platforms.

The advent of the acceptance of third-party signature authentication, or eSignatures, has also revolutionized the permitting process for rooftop PV solar. Many AHJ’s now have portals that allow an organized submission of project applications and drawing sets electronically, in PDF format. Drawing sets and engineering reports can have Professional Engineer’s seals and signatures applied electronically. The 3rd party authentication of the eSignatures allows AHJ’s to be certain that the documents received are indeed those signed and sealed by the Professional Engineer.

At present, the time it takes to get a PV solar construction permit is long, but it can be shortened. And the associated savings in time relate to savings in application and approval costs.

Richard Pantel, P.E., is President of TectoniCorp, which offers the Instant Roof Framing Analysis iRooFA engineering service. His can be reached at [email protected] / 908-507-5500.

iRooFA | www.iroofa.com

Author: Richard J. Pantel, P.E.

Volume: 2022 September/October

.png?r=3883)