Keeping Out of Harm's Way: Top-of-pole trackers

Solar designers and engineers have faced site demands of weather and terrain for as long as solar energy has been around. It's not so much a case of wondering what ever happened to all the available protected, flat, unobstructed and rock-free sites, as much as it is realizing that those ideal locations never really existed in the first place.

Solar panel support structures are often built in exposed areas where they can take advantage of sun exposure. Their foundations drive deep into the earth and must withstand everything Mother Nature dishes out over a 20- to 30-year lifespan.

Designers face a big challenge in finding a site layout with proper ground clearances and minimal shading. Steep grades and aggressive grade changes, along with soft soils, rocky soils, and/or corrosive soils, all make foundation engineering a challenging puzzle that must be solved with conservative safety factors. In order to be permitted, both solar system structures and their foundations must be designed to resist high wind loads, snow loads, and seismic loads. Then, once the site is constructed and up and running, it must further endure heavy rains, ground erosion, flooding, ice storms, and snowdrifts for the remainder of its operating life.

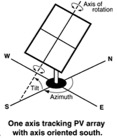

While PV cell and module companies have continued to improve efficiencies and overall performance, individual solar panel efficiencies have begun to plateau. Regardless of what solar panel is used, including the latest bifacial modules, its annual power (kWh) production improves significantly when mounted on sun-pointing or tracking structures. In fact, single-axis solar trackers have been long accepted as the product of choice for the growing utility-scale applications.

Overall design and layout for single-axis trackers used in large solar farms have followed the conventional wisdom of north-south-oriented, "long row" architecture, with continuous structures built as close to the ground as possible. This format keeps the system's wind signature small while optimizing DC collection with strategically placed combiner boxes, inverters, and transformers.

But some sites, where the terrain is prone to extreme weather conditions like flooding and snowdrifts, solar panels require additional ground clearances. The typical long and continuous structure cannot navigate steep grades and grade changes effectively. The structural and electrical advantages of contiguous racking with shared foundations are often outweighed by design, construction, and operations and maintenance inefficiencies.

Commercial, industrial, and residential ground-mount solar systems were the first markets to utilize top-of-pole solar arrays. Also popular in agricultural applications, these decentralized structures inherently offer solutions to extreme weather and terrain conditions.

Independent foundation design for varying site conditions - Since each solar array (8-18 PV modules, over 7kW) can be mast on a single post or pile, the required embedment, casing, and reinforcing can be optimized by exposure and location.

Easy remediation for rocky conditions - If you have driven or augured for post foundations, you know what "refusals" can mean on contiguous rows. Top-of-post tracker structures can be more easily relocated since they are not structurally tied to other arrays.

Arrays can be easily elevated, when necessary - Flood plains, erosion zones, deep snow and drifts, and even vegetation and livestock can be easily mitigated by simply increasing individual post lengths. Think "solar trees" vs "solar carpeting."

Arrays can be easily elevated, when necessary - Flood plains, erosion zones, deep snow and drifts, and even vegetation and livestock can be easily mitigated by simply increasing individual post lengths. Think "solar trees" vs "solar carpeting."

No maximum grade or change of grade limits - In most cases, as long as a proper foundation hole can be excavated, a top-of-pole tracker can be constructed.

More power than rowed single-axis trackers - Top-of-pole single-axis trackers are "polar aligned" (tilted for latitude), generating more kWh per module than horizontal trackers.

Like all solar structures, top-of-pole systems have a downside, too. Taller structures are subjected to higher wind loads, which can lead to deeper or heavier foundation requirements. DC collection design takes on a more decentralized approach. The same goes for powering solar-tracking actuating itself. It's more efficient to turn long rows or ganged rows than independent arrays. Solving for extreme weather and terrain conditions can be costly. But new top-of-pole products offer "passive" tracking drives that autonomously boost power with a single moving part - no motors, no cables, no computers, and no external power.

Simply put, top-of-pole trackers solve common problems associated with extreme weather and terrain. They will never compete on cost with conventional utility-scale solar systems on ideal sites. But remember, conventional wisdom will always make good sense, until the site conditions are unconventional!

Eddie Bugg is Founder of Pursuit Solar, which manufactures top-of-pole tracking solar racks.

Pursuit Solar | www.pursuitsolar.com

Author: Eddie Bugg

Volume: 2020 May/June

.png?r=4745)