Inrush Current Causes Rapid Voltage Change - A barrier to widespread adoption of Distributed Energy Resources

The electric grid has long been recognized as an important engineering accomplishment, enabling modern services that range from life-saving water purification to lighting.

The electric grid has long been recognized as an important engineering accomplishment, enabling modern services that range from life-saving water purification to lighting.

Modern conveniences are integrated so seamlessly into daily life that most people take no notice of the machines and infrastructure operating continuously in the background. The interconnected and expansive electric grid, though it provides safe and reliable power, is fragile as it faces new challenges that were not contemplated in the original design. One such challenge originates from connecting Distributed Energy Resources (DERs) which, by necessity, add large numbers of transformers to the grid, resulting in periodic inrush current events.

What is an inrush current and rapid voltage change?

Most people have experienced the ill effects of inrush current in their daily lives. For example, when a piece of equipment switches on in a building with a commercial sized HVAC unit (or in a home with older appliances) the lights may dim momentarily or electronics may restart. This noticeable power quality issue is the result of a temporary sag in voltage levels that become inadequate to support normal operation.

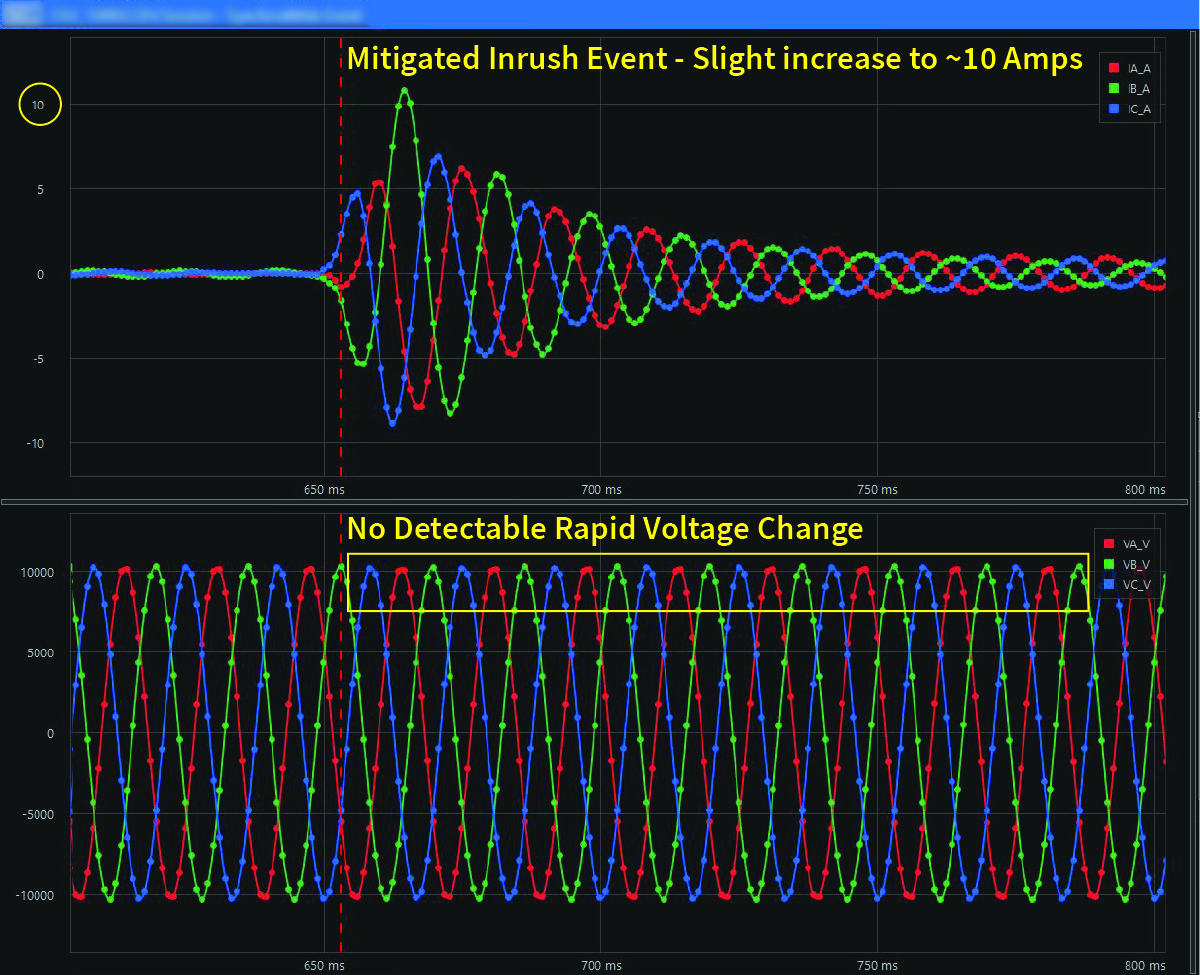

To further explain, when a piece of HVAC equipment switches on, the initial current draw can increase up to 20 times what is required during sustained operation. This initial peak in current flow, called inrush current, triggers a sudden and unexpected electrical load that results in a temporary voltage sag. This voltage sag is called rapid voltage change (RVC).

On a DER, an RVC event occurs when a transformer is reconnected for energization following a loss of grid event. Unlike a commercial sized HVAC compressor, modern DERs use step-up transformers that are quite massive. Multiple 1,800 to 3,500 kVA step-up transformers are commonplace. For perspective, a single 2,500 kVA transformer is equivalent to 500 homes. If the HVAC compressors in all of these homes start up at the same time, the effects would be significant. Further, when multiple step-up transformers are connected in parallel to meet a DER's full generating capacity, the combined inductive load is additive. The massive load is large enough to affect the power quality of the associated grid and its other interconnected customers.

What challenges face DERs because of RVC?

An interconnection study is conducted at any new generation site, during which a power flow analysis models the initial magnetization of the DER's step-up transformers. If the study determines unacceptable levels of voltage sag, the interconnection's request for approval is threatened. A failed interconnection request may result in unplanned capital expenses and, in some cases, the cancellation of a DER's development. Both outcomes stifle broad DER adoption.

In addition, limitations are placed on grid interconnection locations. When scouting land for DERs, the ideal and available sites are frequently on the outer edges of larger communities. These locations have access to the power grid far from central generators and sub-stations. At these distances, the power grid's electrical service has been impacted by upstream loads. Equate the power grid's voltage to the pressure of water in a pipe, and electrical current to the amount of water flowing through that same pipe. The farther it travels from the central source, consumption and inefficiencies reduce both pressure and flow. In the electrical grid, pressure and flow are referred to as stiffness. A stiffness is reduced, the power quality effects of RVC become more pronounced. Therefore, outlying DER locations must overcome more extreme voltage sag to ensure power quality.

Can RVC be mitigated?

Yes. There are several strategies for mitigating the effects of RVC that enable DER interconnections to meet required power quality standards.

- Power grid upgrades

Upgrading infrastructure to better support a DER's point of interconnection may lead to greater circuit stiffness and reduce the effects of RVC. However, these upgrades in the form of larger sub-station transformers, reconductoring, and dedicated feeders are accompanied by capital investments that may be cost prohibitive for a new DER.

- Reduce the load

Redesigning a proposed DER to reduce the total generating capacity will lessen the inductive load because fewer transformers are needed. Decreasing production is an inefficient use of available land, requires re-engineering the proposed system, and lowers the financial efficacy of a project.

- Stagger the timing

DERs with multiple step-up transformers may successfully reduce individual RVC events by implementing an energization timing sequence for each transformer. Typically accomplished by installing medium voltage switches and control, these methods add equipment and cost. They also impact reliability during long term operation.

- Inrush mitigation commercial products

There are a growing number of commercial products that reduce the effects of RVC by employing novel methods such as pre-insertion transformers, resistors, and zero crossing technology. Each solution requires proper evaluation for cost, reliability, operation, and feasibility, as it relates to a DER's unique attributes and the grid's characteristics at the proposed point of interconnection.

Inrush Mitigation Is Necessary for Widespread Adoption of DERs

As the evolution of the power grid accelerates, DERs will represent the majority of new interconnections. Identification of proven, affordable, and reliable methods to mitigate inrush current and rapid voltage change are necessary to achieve the modernization of the grid.

Bradley A. Micallef is President & COO of Solar Operations Solutions, LLC, which delivers industry specific solutions for PV and ESS generators. Transitioning from a prior career in the automotive manufacturing sector, Brad joined the solar industry in 2008. During his tenure in the industry, he has gained broad professional experience in module manufacturing automation, EPC execution, O&M service management, Private Equity Investor asset management, and IPP long term ownership.

Solar Operations Solutions | www.mypv.pro

Author: Bradley A. Micallef

Volume: 2021 September/October

.png?r=5394)