Hot Enough to Chill: The paradox of solar-powered cooling

Solar power has witnessed explosive growth, scaling from just 1 GW to 100 GW in the US under 13 years on a pace unmatched by coal or natural gas. While solar PV typically dominates energy discussions, a highly efficient yet underexplored approach combines solar thermal (PT) collectors with heat-driven chillers to supply both cooling and heating. Unlike conventional vapor-compression systems that rely on electricity, absorption and adsorption chillers use thermal energy and can achieve electrical Coefficients of Performance (COP) above 30 — vastly outperforming standard electric chillers with COPs around 3. Rather than comparing absorption and adsorption technologies or PV versus PT panels in depth, this article focuses on how the interaction between collector temperature and chiller performance affects overall system efficiency.

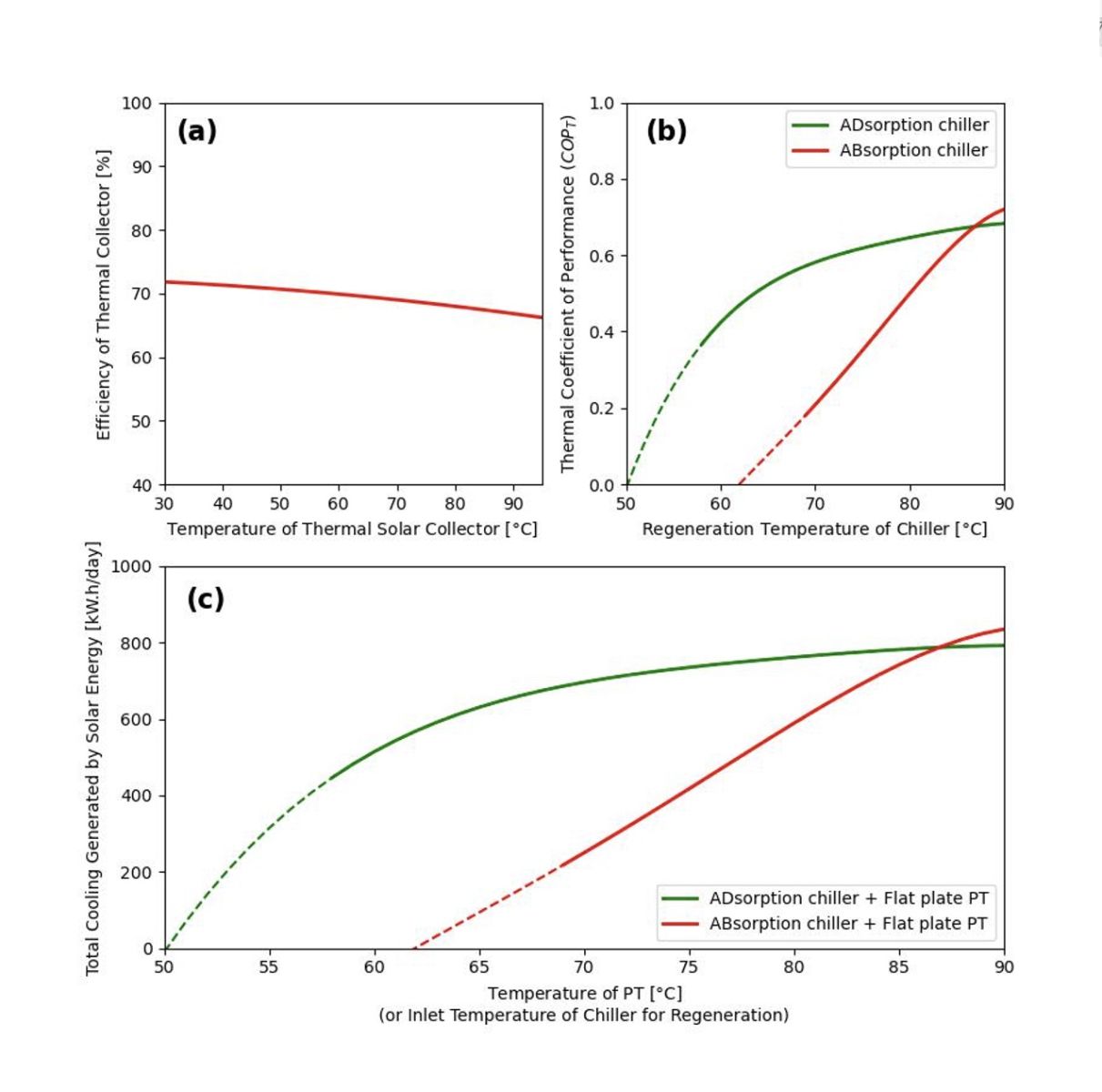

System performance is a balancing act: PT collector efficiency drops as their temperature rises, yet chillers require higher input temperatures for optimal function. Absorption chillers need higher regeneration temperatures than adsorption chillers, which can operate effectively at 10–15°C lower. To visualize this dynamic, we use real-world data from commercial products, applying it in a modeled scenario set in San Jose, California. In July, when the solar irradiation averages 7.23 kWh/m²/day and peak temperatures range from 27°C to 34°C, we assume 240 m² of collector surface (equivalent to around 100 flat-plate panels), chosen over vacuum tubes for their efficiency on a gross area basis.

Figure 1. (a) Efficiency of a thermal solar panel versus the operating temperature of PT. (b) The thermal Coefficient of Performance (COP) of heat-driven (Adsorption and Absorption) chillers versus the regeneration temperature. (c) The total cooling generated by one hundred solar panels combined with heat-driven chillers.

Figure 1. (a) Efficiency of a thermal solar panel versus the operating temperature of PT. (b) The thermal Coefficient of Performance (COP) of heat-driven (Adsorption and Absorption) chillers versus the regeneration temperature. (c) The total cooling generated by one hundred solar panels combined with heat-driven chillers.

Figure 1(a) shows how collector thermal efficiency declines with increasing temperature, while Figure 1(b) compares the COP of typical absorption and adsorption chillers, highlighting adsorption’s ability to operate at lower temperatures. Using solar data and collector specs, we estimate thermal energy output and corresponding chiller performance across a range of operating temperatures. Figure 1(c) illustrates that adsorption chillers can maintain cooling output across a wider range, making them advantageous in systems where sustaining high collector temperatures is difficult.

Beyond cooling, these systems offer seasonal versatility. In summer, they deliver cooling and domestic hot water; in winter, they can operate in heating mode, functioning like heat pumps. Some chillers can amplify thermal output by up to 1.5 times the collected energy, potentially eliminating the need for gas heating and enhancing overall efficiency. However, seasonal challenges exist; lower sun angles, increased cloud cover, and less direct radiation in non-summer months lead to reduced collector output and lower operating temperatures, which can impact year-round system efficiency.

Looking at the numbers: with ideal July conditions in San Jose, a 240 m² flat-plate setup integrated with an adsorption chiller delivers approximately 787 kWh of cooling and 1,736 kWh of heating per day. When compared to baseline systems using grid electricity and gas (with assumptions of $0.15/kWh for electricity, $13.85/Mcf for gas, and a 0.2 kgCO₂e/kWh grid emission factor), this translates to about $118 in daily energy savings and a reduction of 198.8 kg CO₂e in emissions.

If the same surface area were allocated to PV panels instead, the system would produce around 296 kWh of electricity daily — worth $44.40 and reducing emissions by 59.2 kg CO₂e. While this is substantial, it’s notably less than what the thermal-chiller combination can offer when both cooling and heating needs are addressed.

A compelling solution lies in hybrid photovoltaic-thermal (PVT) panels, which harvest both electricity and heat. With combined efficiencies reaching 90 percent or more, PVTs enable year-round applications — space heating in winter and thermal-driven cooling in summer — while freeing up electrical capacity for other uses.

Dr. Bahman Lashkari, Ph.D., P.Eng, is Director of Technology Developments and Arshad Singh is a Mechanical Engineerat Enersion, which developed a reversible heat pump system utilizing adsorption chilling capable of heating and cooling diverse commercial and industrial sites.

Enersion | enersion.com

Author: Dr. Bahman Lashkari, P.Eng. and Arshan Singh

Volume: 2025 September/October

.png?r=7631)

.png?r=1729)