Extending the Circle of Life Why module reuse is essential for the PV industry

Product lifecycles fundamentally consist of the build, the use, and the inevitable end-of-life (EOL). As is common in our disposable society, strategic planning for extending life is often left out of the equation. Within the solar industry, development of photovoltaic (PV) systems, large and small, often include the basics of development (cost/performance analysis, build out), operation (energy yield, maintenance), and EOL, commonly based on years of performance and warranty. While the latter often results in tossing aged PV modules into landfills, these panels may still perform satisfactorily or be refurbished to operational conditions.

Product lifecycles fundamentally consist of the build, the use, and the inevitable end-of-life (EOL). As is common in our disposable society, strategic planning for extending life is often left out of the equation. Within the solar industry, development of photovoltaic (PV) systems, large and small, often include the basics of development (cost/performance analysis, build out), operation (energy yield, maintenance), and EOL, commonly based on years of performance and warranty. While the latter often results in tossing aged PV modules into landfills, these panels may still perform satisfactorily or be refurbished to operational conditions.

Even while more and more states and municipalities are reclassifying PV modules as hazardous materials (thereby limiting how and where they may be disposed), the option of discarding into landfills continues to be one of the easiest, cheapest, and currently legal methods. Discarded panels often originate from natural disasters, damage during transit or installation, lack of performance, decommissioning, or repowering. Add in ongoing high transportation costs, and even the most well-intended corporate sustainability goals may not financially allow for recycling. A better option is bringing new life to panels through sustainable remanufacturing - is a positive for the environment - and often allows the new system owner to acquire panels at an appreciable cost savings.

An International Renewable Energy Agency (IREA) report, "End-of-life management: Solar Photovoltaic Panels," predicted that, as the global PV market increases, so will the volume of decommissioned PV panels. Photovoltaic panel manufacturers typically rate the operating life of panels to an average of 25 years. The global PV market size is expected to reach USD 286.64 billion by 2030. The industry is anticipated to advance at a CAGR of 7.8 percent from 2022 to 2030. Coinciding, the IREA estimated that solar panel waste worldwide could reach 78 million metric tons by 2050. This is of critical concern, as some solar panels contain chemicals that can leach into the soil and cause a variety of environmental problems, including toxic drinking water.

The Environmental Protection Agency has stated that solar panels have different metals present in the semiconductor and solder, like lead and cadmium, which are harmful to human health and the environment. Federal hazardous waste regulations apply to solar panels that have reached the end of their usable life. Discarded panels would be considered hazardous solid waste by meeting the characteristic of toxicity under Resource Conservation and Recovery Act’s (RCRA) Subtitle C.

Fortunately, solar panels that are properly recycled are eligible for regulatory exclusions under the RCRA in states that have adopted the Definition of Solid Waste Rule. This is a regulatory exclusion for the hazardous secondary material that is recycled, as long as certain criteria laid out in the regulations are followed. This conditional exclusion is designed to encourage recycling of materials by third parties while still providing a regulatory framework that prevents mismanagement. For damaged panels, recycling is evolving as a viable alternative.

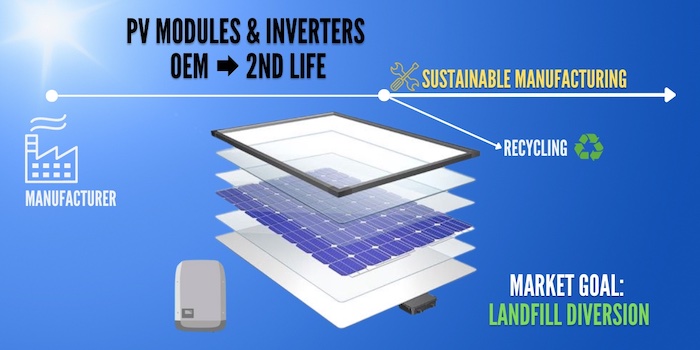

Another option is second life services in the form of sustainable manufacturing. This allows owners to sell their used panels, rather than paying for recycling. In most cases, as long as the glass layer is not fractured, the junction boxes, cabling, backsheet, and framing can all be replaced. The PV modules can then be tested for suitable output and reintroduced back into the market onto rooftops, carports, field, etc., and end up generating the same electrical output or better than when taken offline. The remanufactured panels are economically advantageous in that they are sold at an appreciable savings to the installer or end-user. This allows for greater opportunity for solar usage, often in residential, agriculture, nonprofit, and evolving markets where cost sensitivity may be a limiting factor in solar adoption.

While replacing underperforming or damaged panel components is essential, verifying that the system is capable of generating optimally is vital. Each panel should be flash tested, both prior to and following any refurbishment. A Certificate of Salvage (COS), along with tracking serial numbers, provide reassurance of accountability. While some remanufacturing entities may extend a partial warranty, most do not at this time. This makes proper testing and documentation even more vital.

Second life methods may apply due to change of ownership in a home or building, where the new asset owner chooses not to retain the solar system because of age, aesthetics, or some other reason. This scenario generally allows for money to be made from selling the decommissioned panels to a remanufacturing facility. Another opportunity presents itself during repowering, whereby new technologies may allow for improved performance; the existing panels are swapped out for newer versions. Also, environmental impacts may warrant remanufacturing. For example, lightning may reduce performance, yet often the solar cell layer is still capable of capturing and funneling the sun’s energy, while only the junction box and connectors may need to be replaced, instead of the entire panel.

When panels are not recoverable, most commonly due to broken glass, proper recycling is a viable option. To date, there are only a few recycling facilities specializing in solar within the United States, and even fewer dedicated to remanufacturing. While the current economics of recycling (primarily due to transportation costs) are often not favorable for solar panels, technological efficiencies are being introduced to make extracting precious materials and redirecting those reusable materials back into the manufacturing process a viable option.

As supply chain constraints have negatively impacted most all industry sectors, access to solar components has been challenging worldwide. Coupled with tightened global economics and the exponential growth in solar, it is essential for the industry developing alternative sourcing channels. The sustainable remanufacturing market presents an ideal solution by giving life to panels that would otherwise be unused or polluting our landfills. Second life remanufacturing and recycling are crucial in supporting landfill diversion and access to vital energy, and helping the solar panel lifecycle come full circle.

Moises Aguirre is Director of Business Development at Ontility, a BBB Industries company that specializes in buying and selling a full array of solar products, and providing customers with end-to-end customizable solar solutions.

Ontility | www.bbbind.com

Author: Moises Aguirre

Volume: 2022 November/December

.png?r=8058)