Driven Foundations for Trackers and Fixed Racks – W vs. C

Driven Foundations for Trackers and Fixed Racks – W vs. C

by Matt Kesler and Dave Wilson

In the first quarter of 2023, 6.1 gigawatts (GW) of new photovoltaics capacity were installed in the United States, with more than 80 percent of it on ground-mounted fixed racks or trackers. This required about 1.5 million foundations, including ground screws or poured concrete.

By far, the most common foundation type is posts or piles that are driven vertically into the ground. They are less expensive to manufacture and install than ground screws or “pour-in-place” foundations. Driven piles are normally referred to as either “W” (also known as “I” or “H” piles), or “C” (roll-formed).

Descriptions

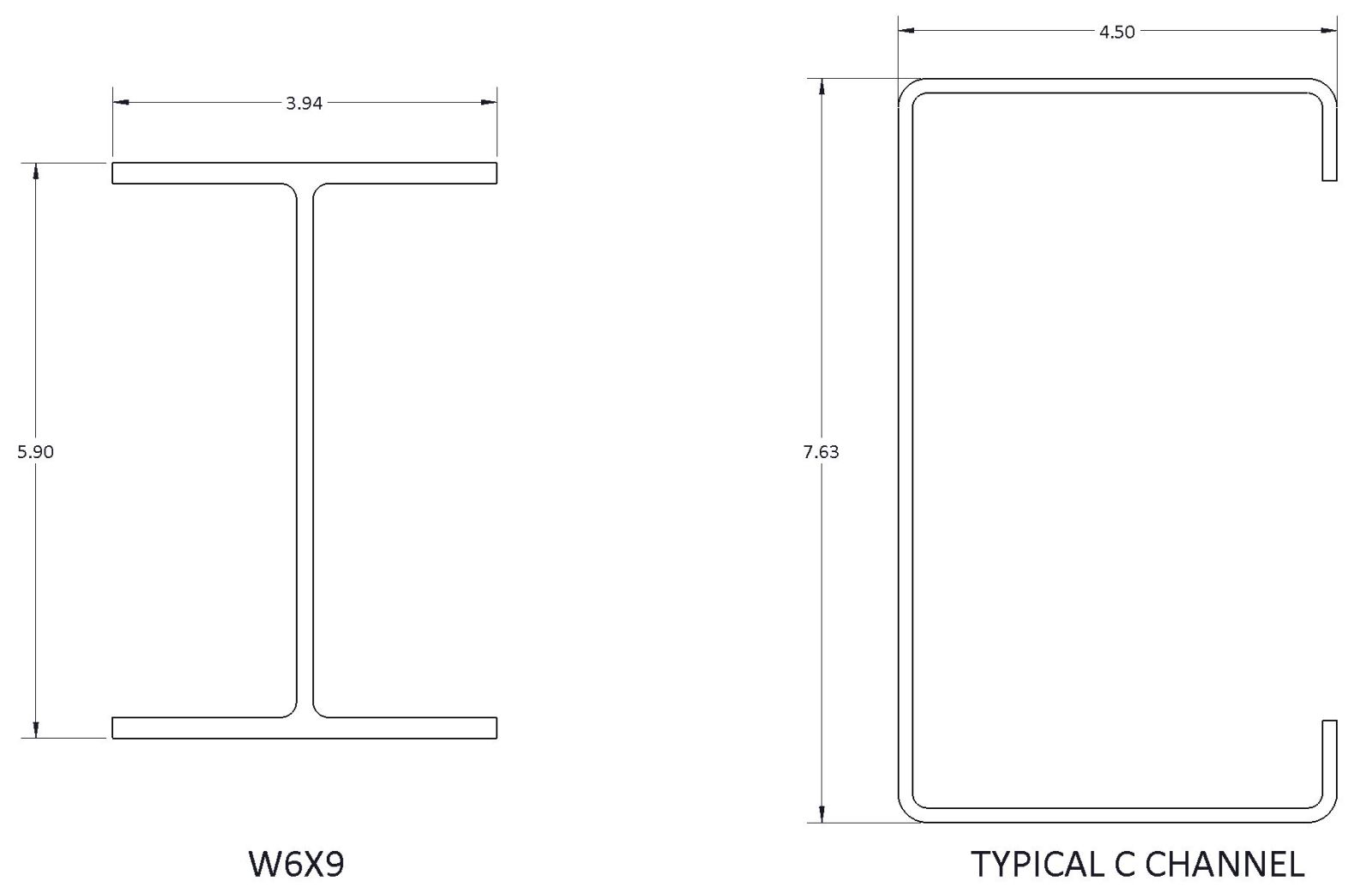

W piles have two sides and a “web,” and the thickness of the web can be different from the thickness of the sides. W piles for solar racks and trackers are most common of the W6 family (height approximately 6 inches), and either 7 pounds per square foot (W6X7) or 9 pounds per square foot (W6X9). W piles are typically made of steel with yield strength about 50 ksi (thousand pounds per square inch).

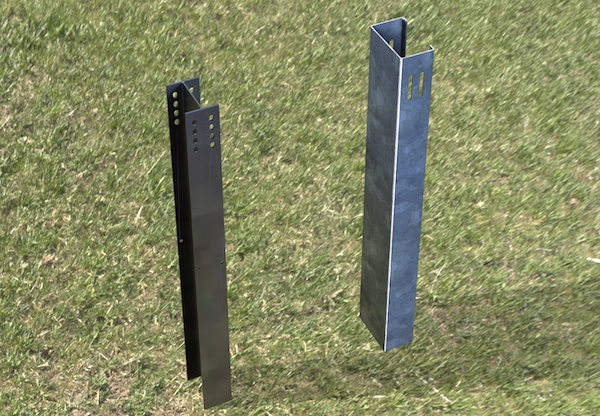

Figure 1: Typical W and C piles.

A typical C pile is about 4.5 inches wide and 7.625 inches across, with “returns” about 1 inch. The thickness or gauge of the material in a C pile is uniform, typically between 0.100 inch and 0.150 inch. C piles can be made of steel with a higher yield strength, such as 80 ksi.

Both W and C types typically have holes or slots near one end to enable attachment of the structure.

Structural considerations

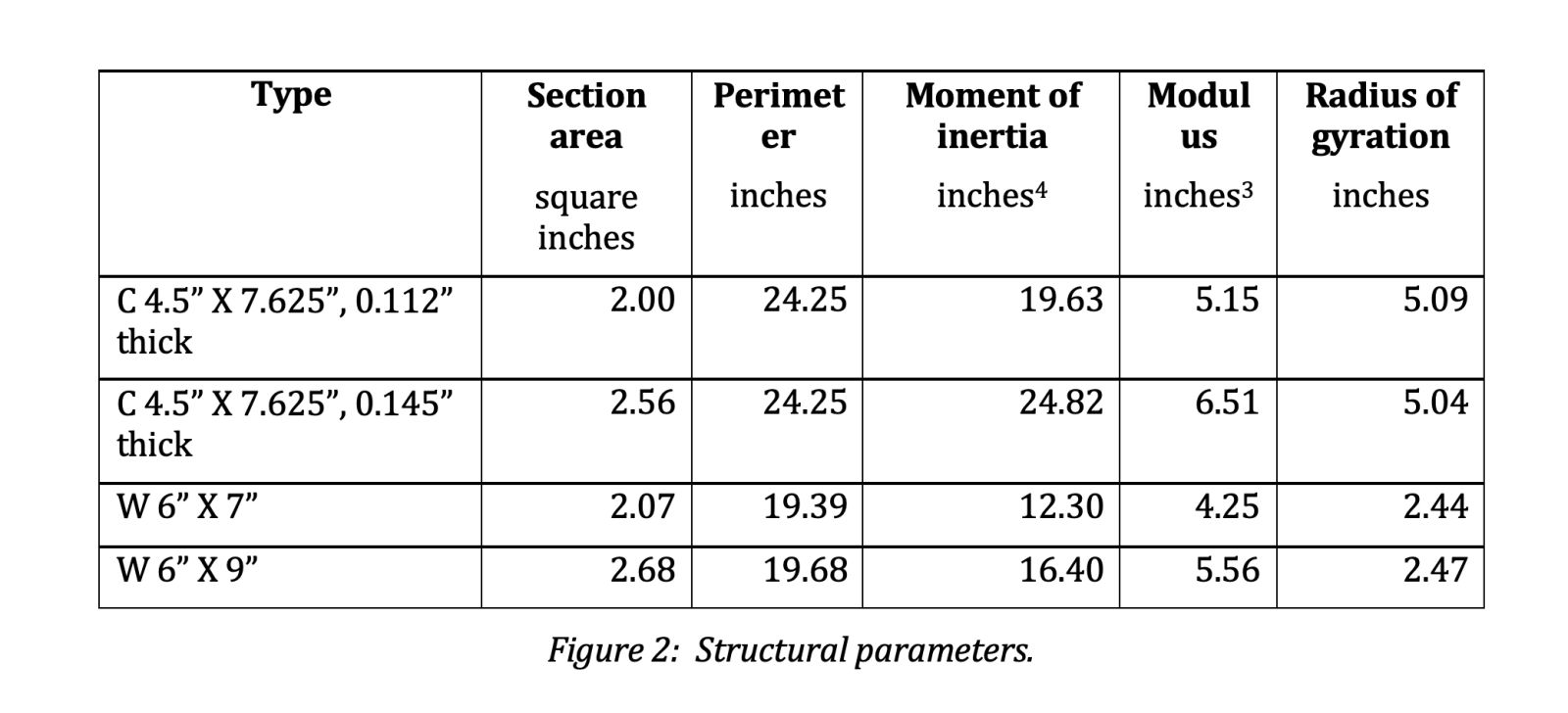

Because the section area of the two pile types is similar, they are approximately equally easy to drive into the ground.

C piles have a somewhat higher perimeter, which means a greater surface area and greater resistance to uplift forces (they are harder to pull out of the ground once driven), which is a significant advantage.

C piles show a higher moment of inertia, which may make them more resistant to deflections. In some cases, this may mean reduced embedments (length of the post below ground), and thus lower cost.

C piles also show a higher section modulus, or greater resistance to bending. This means that in some circumstances, the section can be smaller and the cost per foot reduced.

The greatest risk to driven posts or piles in solar applications is buckling. A design’s strength against buckling can be evaluated by considering its radius of gyration, defined as the imaginary distance from the centroid, at which the region of the cross-section is imagined to be concentrated at a point to achieve the same moment of inertia. The two C pile designs shown have a radius of gyration approximately twice that of the W piles shown (in figure 2), indicating they will be at lower risk of buckling.

Manufacturing

W piles must be forged at high temperature (a slow and energy-intensive process), then cut to length, with holes and slots cut in a secondary operation. Then they are hot dip galvanized, which is an expensive and environmentally challenging operation.

C piles can be roll-formed at low temperatures (a less energy-intensive process).

When C piles are manufactured, holes and slots can be punched inline, and the piles can be cut to length inline. The steel is pre-galvanized, so no hot dip galvanization step is needed.

Site conditions and installation

While both W and C piles can be used in various soil types, they are usually not installed in rocky ground; ground screws or poured concrete are more successful in that scenario.

There may be some hard soils – such as thick caliche – where W piles drive better than C piles.

Driven piles work best when the slope is no greater than about 20 percent, or 11 degrees.

Both types require common pile-drivers with similar heads to keep the piles straight as they are driven. Process time is also similar.

Number of piles needed

Whether a fixed rack or a tracker design, careful structural analysis of the entire system results in appropriate spans (horizontal distance between posts).

In some cases, spans may be longer for C piles than for W piles due to a combination of the factors described above: perimeter, moment of inertia, section modulus, and radius of gyration. This may translate into fewer posts per megawatt (MW) and lower total cost for all the foundations required to build a solar power plant.

Summary

W piles are sometimes preferred for their familiarity within the industry and because they can be driven in a broader variety of soil types. C piles have significant structural advantages that can mean lower total cost for some solar power plant designs. While W piles have been used more broadly and for more years than C piles, both types have now been proved through use at many US solar sites.

Matt Kesler is Director of Solar Technology, and Dave Wilson is Director of Solar Engineering at OMCO Solar. To obtain a copy of the OMCO Solar Pile Guide, email [email protected].

OMCO Solar | omcosolar.com

Author: Matt Kesler and Dave Wilson

Volume: 2023 September/October

.png?r=4985)