DC-Coupled Solar plus Storage: Electrical system design challenges

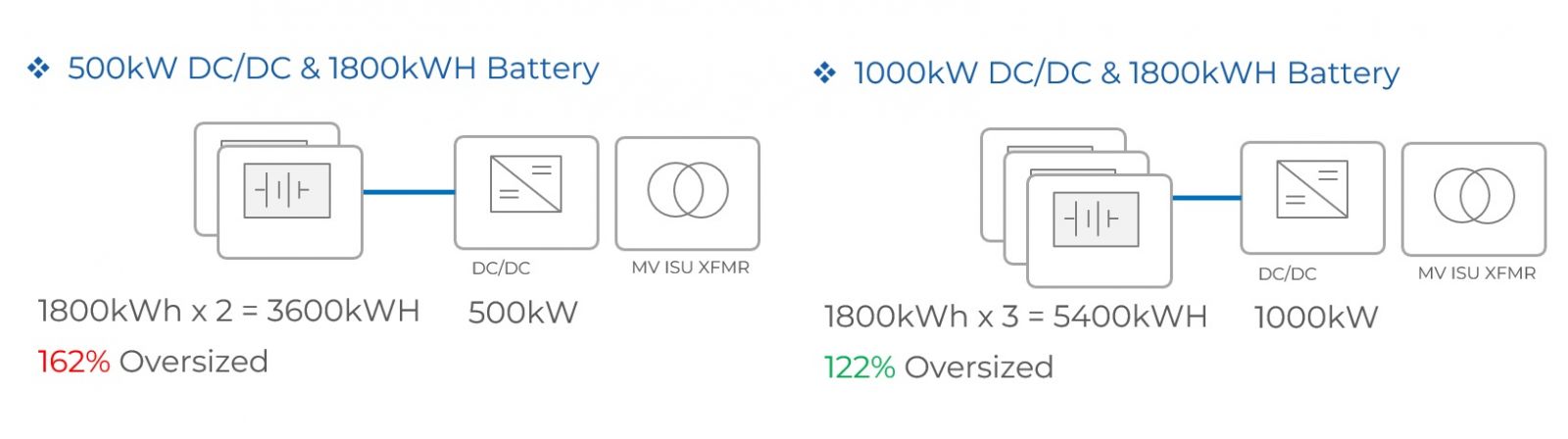

At the very start of the process, a DC-coupled electrical system design is a challenge that requires complex analysis. The batteries need to be balanced across the DC/DC converters, and each converter should be balanced through the photovoltaic (PV) DC/AC inverters. In a typical AC-coupled system, AC inverters range in size from 3MW to 4MW, if a central inverter is being utilized. Currently for DC-coupled systems, the most readily available commercial DC/DC converter is 500kW, or a 1/6th to a 1/8th of the size, which creates restricted battery sizing requirement and requires design analysis. As such, it is difficult to appropriately size the battery racks to account for the energy duration the system requires. Fortunately, more battery vendors are offering modular DC block systems that allow integrators to size the system at a more granular level; on the converter side, there are development efforts for larger systems that will also provide design flexibility for larger battery pairing.

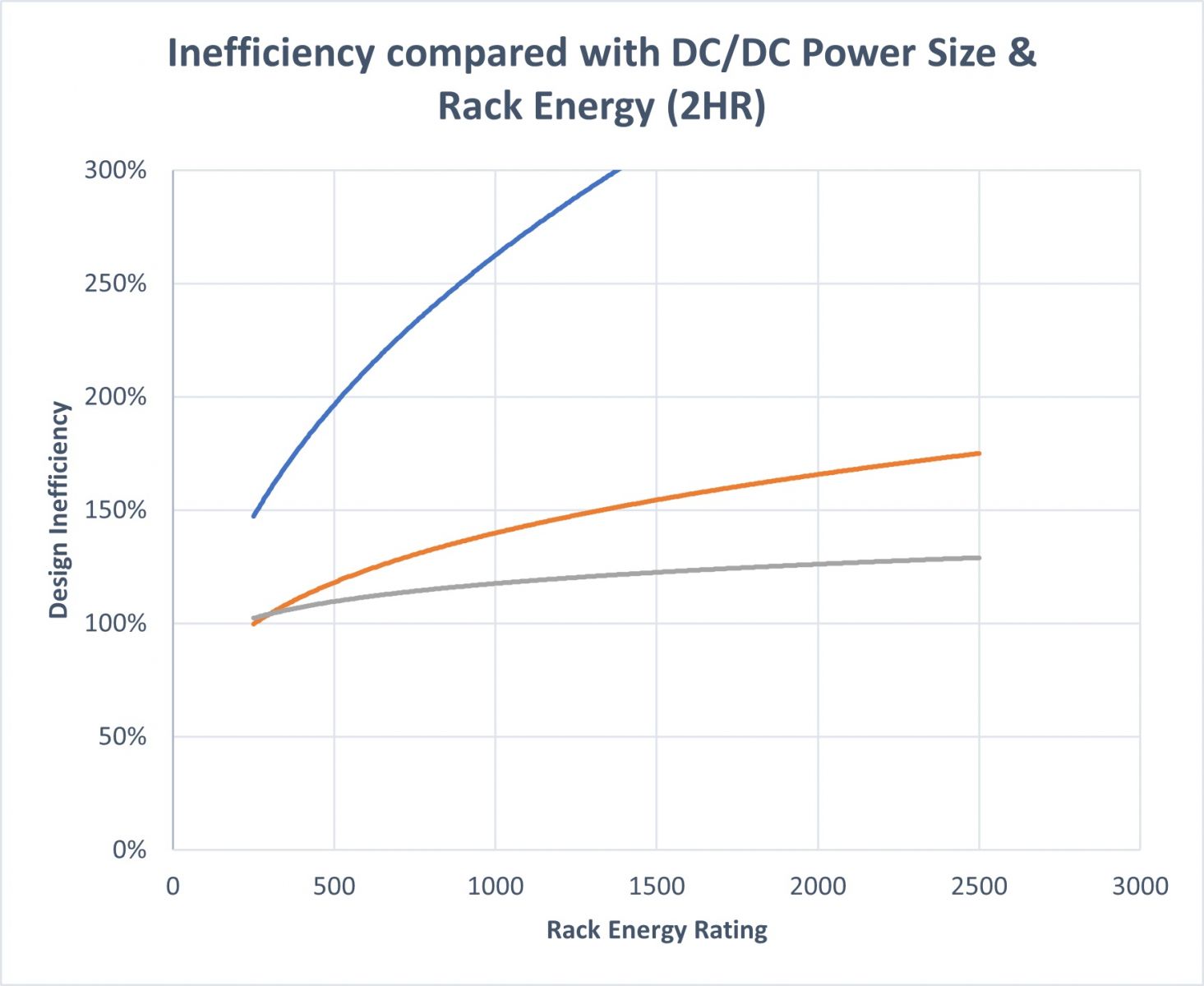

Figure 1: Efficiency gained in a 2-hour system with better sizing of battery and converters

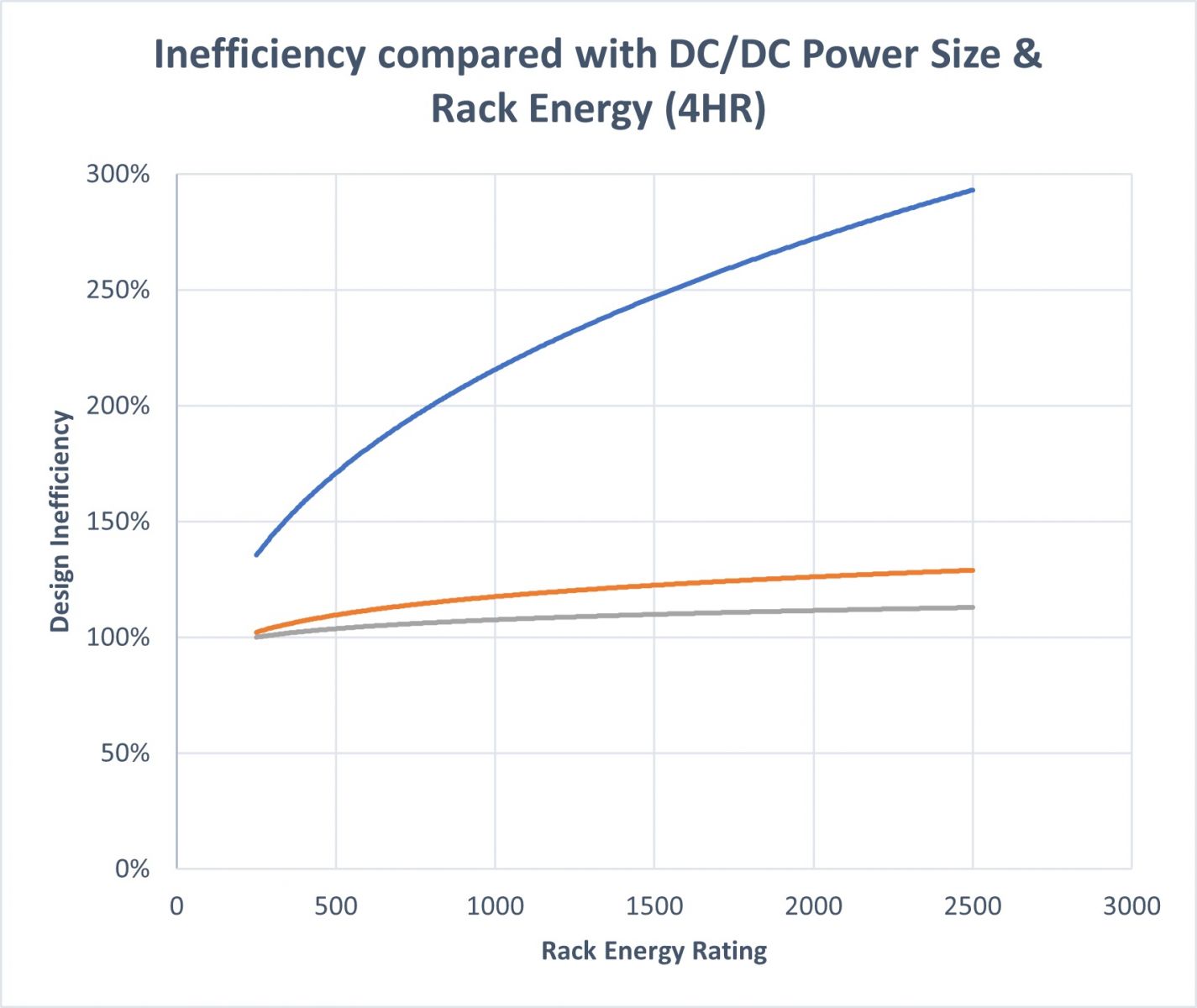

In designing the system, it is essential to consider rack usable energy rating (how much energy can be output from a given battery) and DC-converter size. As shown in Figure 1 above, low converter power rating paired with high energy battery system will yield increased inefficiency in the system, leading to lower optimization capability, while higher power converter rating will provide more optimal design considerations with increased design efficiency and design flexibility. Pairing a 2500kWh battery system on a 250kW converter is certainly not the best configuration or design (500kWh energy required for 2-hour and 1000kWh required for 4-hour systems). Evaluating optimal converter and battery system pairing is critical to system design considerations while targeting optimal levelized cost. Larger converter sizes and smaller battery unit energy rating provides more design flexibility for more optimal design  factors.

factors.

Figure 2 Efficiency gained in a 4-hour system with better sizing of battery and converters

Any DC/DC converter is limited by its maximum rated current, as is the case with any power conversion system. Much like a photovoltaic (PV) inverter, which is dependent on the DC voltage condition of the PV, the DC/DC converter for the battery is limited by the maximum power that can be output. This, in turn, may be affected by temperature-based power de-rate factors that could be 10 percent or more. This requires careful project level analysis based on battery charging and discharging characteristics, as well as solar operational voltage.

While converter sizing is a micro-design consideration that needs careful study, finding DC to AC ratio, also known as Inverter Loading Ratio (ILR), is critical to optimize DC-coupled projects. DC/AC ratio is defined as the nameplate DC power of the modules versus the rated nameplate AC power of the inverter. The maximum DC power is limited by land constraints, and the maximum AC power is limited by interconnection agreements for solar power plants. Optimizing the DC-coupled solar plus energy storage is more complicated, as additional PV clipped energy that can be captured by the energy storage system needs to be taken into consideration. An in-depth analysis of the DC cost of the system versus the value of clipped energy is needed to minimize the Levelized Cost of Energy (LCOE) of a solar-plus-storage project, while maximizing the megawatt-hours (MWh) of solar-generated electricity fed into the grid. For example, as the cost of DC systems or PV modules goes down, developers tend to choose a higher DC to AC ratio. In addition to the financial considerations above, engineers on the project need to make sure they are not exceeding the maximum short circuit of PV inverters.

Technical challenges: short-circuit analysis

After determining the PV DC and AC sizing, a short circuit study is required to ensure that the short circuit current requirements are met. The NEC code 690.8(A) addresses these requirements. The engineer of record (EOR) must evaluate and review PV panel spec, DC/AC ratio, number of strings per inverter, string sizing, and detailed project drawings. In many cases with the PV inverters available in the market, the DC converters are connected directly to the inverter’s internal DC busbar, so the Battery Energy Storage System (BESS) short circuit needs to be added to the overall short circuit withstanding of the power conversion system. An initial easy approach – to ensure that we are not exceeding the peak fault of the inverter – is to multiply the peak fault current rating from the battery vendor by the number of battery units in parallel, to see if this is less than the allowed fault current at the DC/AC inverter terminal. In addition to peak fault current calculation, fuse rating studies need to be performed to ensure the proper overcurrent protection of the energy storage system design.

In analyzing these design challenges for a DC-coupled solar plus storage system, an engineering and design team can find the right balance between available space for the project and the cost of the PV and battery system, to determine optimal levelized cost of energy for the solar and energy storage plant. The addition of storage to a solar project, though increasing design considerations and complexity, creates dispatchable power plants that can improve grid reliability and stability all over the world.

Hoss Darvish, P.E., is the Manager of the Design & Engineering team, and Ray Saka is Vice President of Sales, Product Management, and Services at IHI Terrasun Solutions, a solar + storage systems integrator, control system developer, and lifecycle services provider for utility-scale projects.

IHI Terrasun | www.ihiterrasun.com

Author: Hoss Darvish and Ray Saka

Volume: 2022 September/October

.png?r=2252)