A Short Guide to Solar Panel Cleaning Machinery and Robotics

In the United States, it is estimated that 1.1. Billion solar panels will be going up in the next 8 years just for the commercial, industrial, and utility-scale segments. As solar installations grow worldwide so does the need for cleaning them. With the solar panel cleaning market continuing to expand, it's a good time to learn about the machinery and robotics available to help you face each cleaning challenge with more success. Keep in mind, these guidelines are for the commercial, industrial, utility-scale segments only, not residential.

What is the ideal solar panel cleaning machine? That depends. The right machine is specific to the solar installations you have to clean, the resources available to clean it, and how your portfolio of cleaning jobs will be comprised. Most O&M, solar panel cleaning companies, EPC's, etc. have a portfolio of solar installations. It is important to choose the machinery that will help you with all the installations in your portfolio. It is also important to consider labor type (skilled vs unskilled), logistics, CAPEX, OPEX, accessibility issues, and more.

What machinery allows you to clean each installation type efficiently?

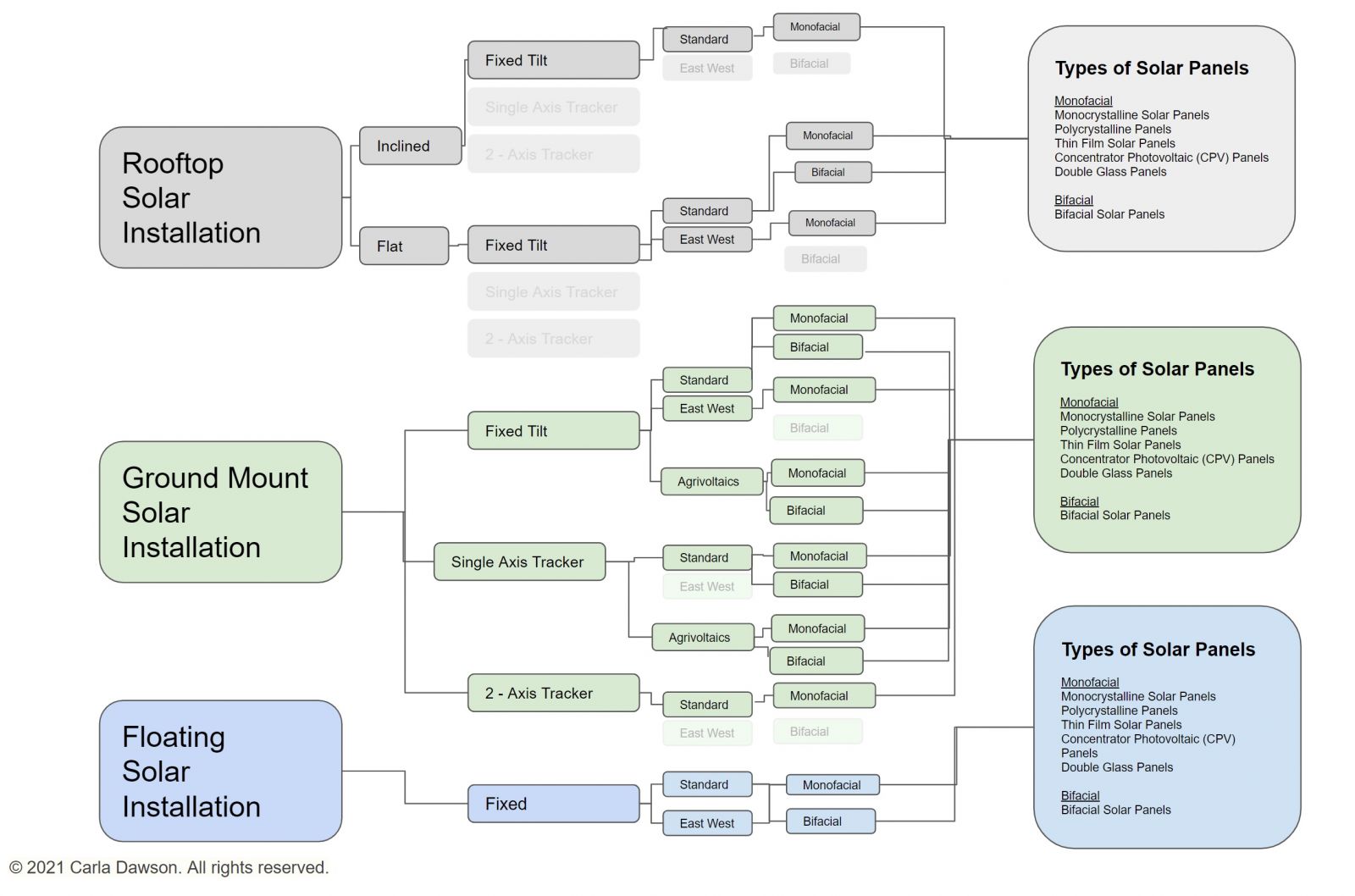

Solar Installations Types - Commercial & Industrial (C&I)

Typical C&I Solar Installations.

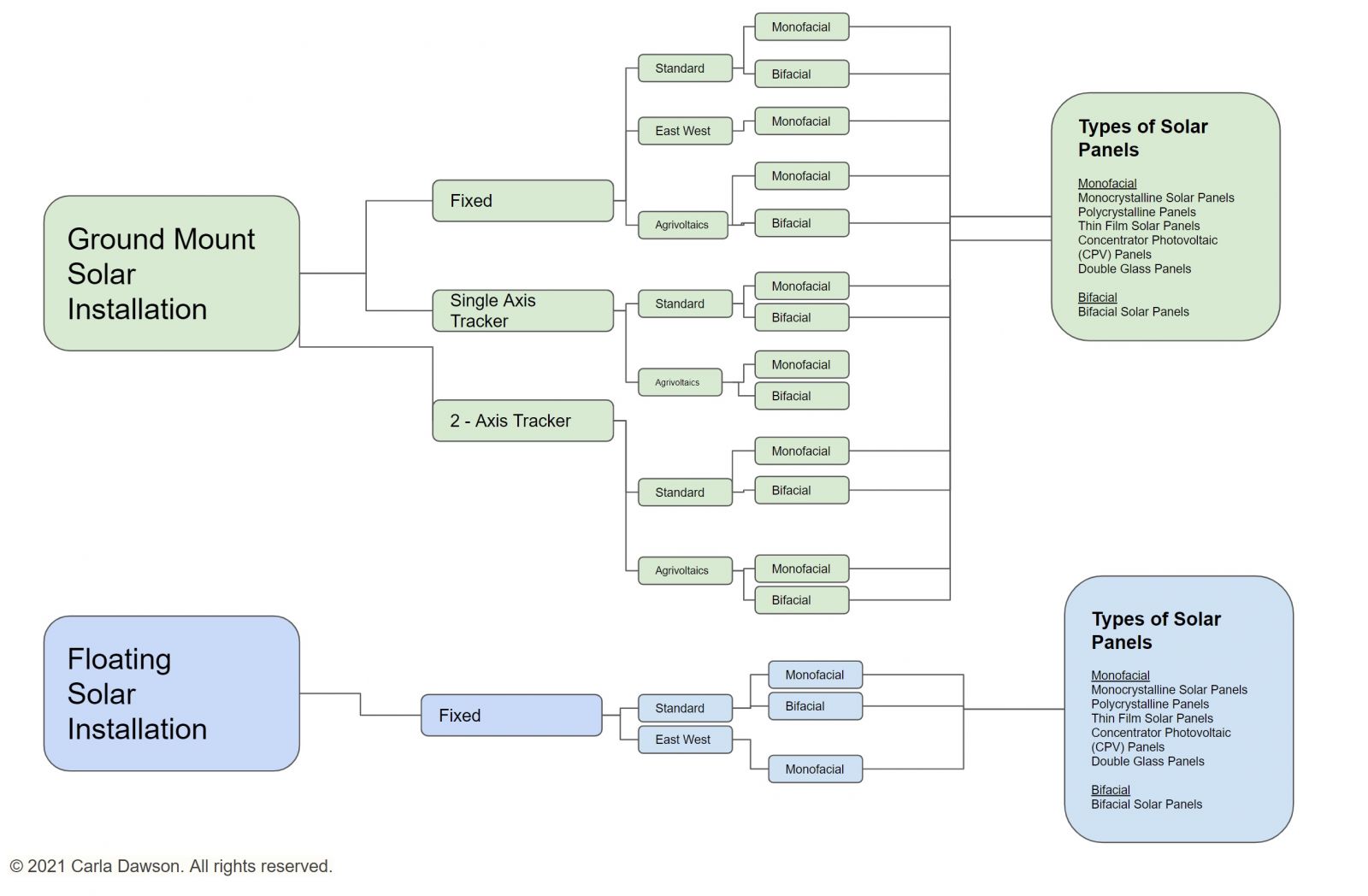

Solar Installations Types - Utility-Scale

Here are some important Concepts to Consider when analyzing the machinery and robotics:

Versatility

As your portfolio of solar installations grows and changes over time, will the machinery allow you to clean each new installation that is added?

Accessibility / Setup -

How easy or difficult is it to access the solar panels with the machinery you have chosen? Getting setup is a significant part of the job and generally speaking, the easier you can get set up the more productive you can be.

Rooftop

If the aerial lift cannot reach the solar panels, can you get the job done? If so, how?

Are the gaps between arrays an issue? How can you get the machinery from one array to the next?

Ground - Mount

Is the spacing between the arrays wide enough for the machinery or cleaning team?

Is there a drive shaft that impedes your access or complicates your operation?

How far is the installation from where the cleaning crew lives/works?

Floating

If you need to clean a floating installation, what machinery will allow you to do the job safely?

Logistics

Logistics is part of Accessibility but it has to do more with getting the machinery to the site. Do you need a flatbed truck or can you get the machinery out to the site with a van or pickup truck and trailer? How do you unload the machinery and how many operators do you need to do this?

Worker Type

Do you need skilled workers or can unskilled workers do the job? Do you have labor shortage issues and is this going to impact your operations?

Power Source & Power Source Management

You need to power the machines and in some cases the water pumps and water treatment devices. How easy or difficult is it to keep the operation going?

Water Consumption

Solar panel cleaning should be done with treated water. How much water does your machinery use?

Productivity Levels

What does the average solar panel cleaning operation look like and what are your productivity levels? Go beyond panels per day. Understand the solar panel cleaning system and see how many operators are needed as well.

Machine Maintenance

How is the machine maintained? What are the parts that wear and tear? How much do they cost? What is the expected lifetime of the machinery? Does the local distributor have parts in stock?

Carbon Footprint

How are the machines powered? Are they carbon-based or clean energy?

System CapEx

Each machinery type requires a long list of complimentary items. Understand the solar panel cleaning system capital expenditure not just the cost of the machinery.

System OpEx

Each solar panel cleaning system has to be maintained. Look into these costs and frequency.

Commercial, Industrial and Utility-Scale Solar Panel Cleaning Machinery

The guide below is not based on specific machines with specific brands but rather a generalized overview of each machinery type. There are significant differences between machine brands. The statements below are general guidelines.

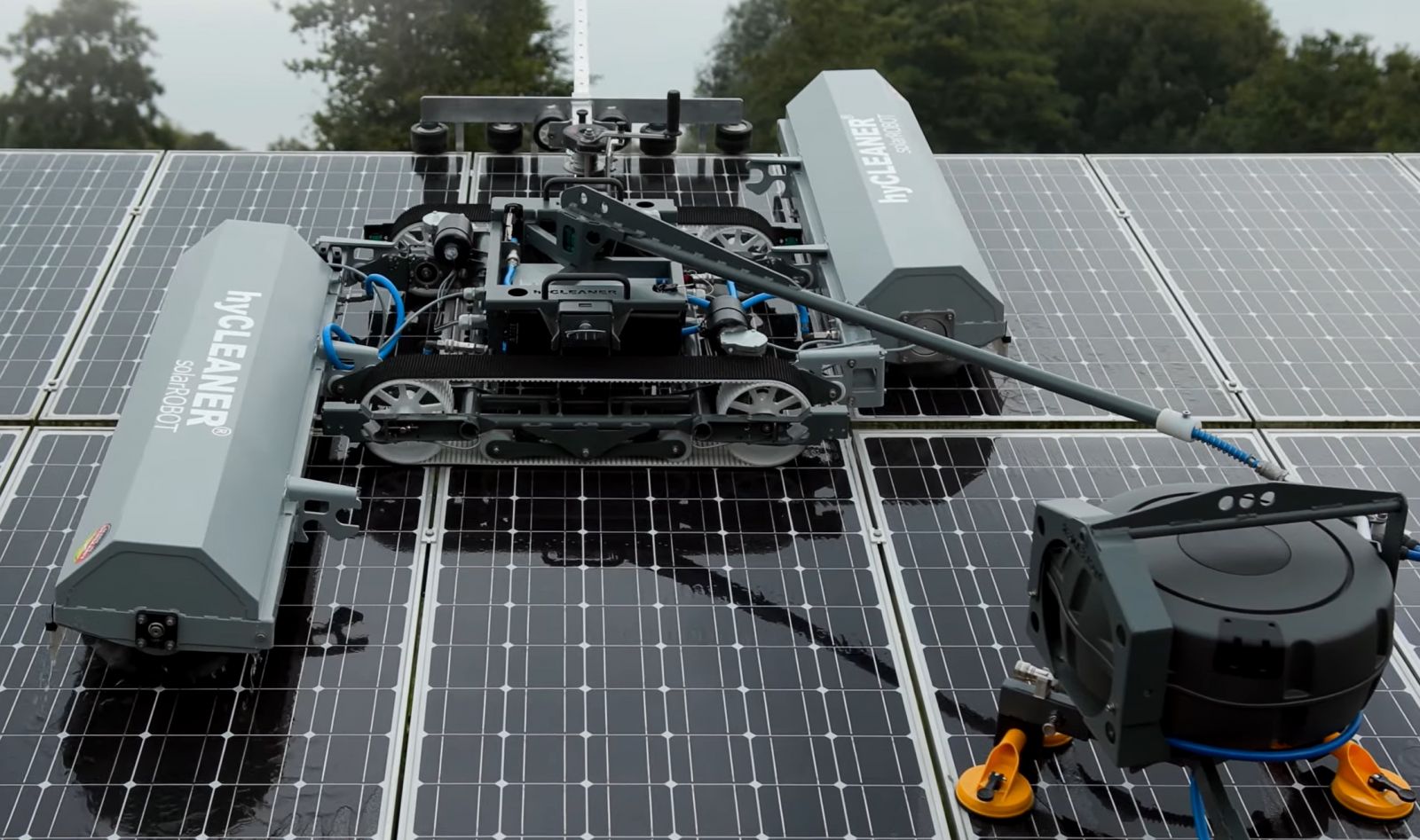

Solar Panel Cleaning Robotics

Solar panel cleaning robotics is a semi-automated solution that works for C&I and utility-scale installations.

Source: hyCLEANER

Versatility - High Versatility

Accessibility / Setup - Relatively easy setup. An aerial lift may or may not be necessary.

Logistics - Van, Truck, or pickup truck + trailer

Work Type - Unskilled with minor training

Power Source & Power Source Management - Battery, Battery Charger

Water Consumption - Low end

Productivity Levels - High end

Machine Maintenance - Brushes and batteries need to be replaced

Carbon Footprint - Battery based

System CapEx - Mid-range

System OpEx - Mid-range

Powered Lift and Shift Solar Panel Cleaning Machinery

Powered Lift and Shift is a semi-automated solution that generally has the following characteristics.

Source: SCM Solar

Versatility - Low end. The width of the machine defines the installation you can clean. Not applicable for inclined rooftop and more. For utility-scale installations, you can use multiple machines at the same time.

Accessibility / Setup - Relatively easy setup.

Logistics - Van, Truck, or pickup truck + trailer

Work Type - Unskilled with minor training

Power Source & Power Source Management - Electrical, long power lines have to be managed.

Water Consumption - Low end

Productivity Levels - High end

Machine Maintenance - Brushes need to be replaced

Carbon Footprint - Electrical, but in many situations, you need a generator to power them.

System CapEx - Mid-range

System OpEx - Mid-range

Brush & Lift / Tractor Brush Solar Panel Cleaning Machinery

Brush & Lift / Tractor Brush is a semi-automated solution where a brush is attached to an aerial lift for rooftop installations or it is attached to a tractor or excavator for ground-mount installations.

Source: Sunbrush USA

Versatility - Mid-range, on a rooftop, you can only clean the panels that are accessible from the aerial lift. On ground mount installations, drive shafts and narrow spacing reduces accessibility to the panels.

Accessibility / Setup - Relatively easy setup.

Logistics - For ground mount installations you need a flatbed truck to get the equipment out to each site.

Work Type - highly skilled. Licensed tractor driver that has been trained to clean solar panels.

Power Source & Power Source Management - Gas-based.

Water Consumption - Low end

Productivity Levels - High productivity levels

Machine Maintenance - Mid-range

Carbon Footprint - Gas based

System CapEx - High End

System OpEx - High End

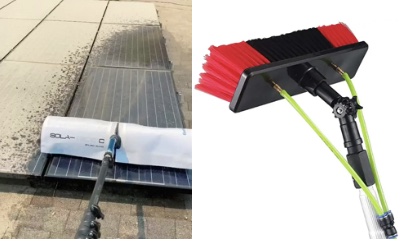

Manual and Powered Water-Fed Pole

There are many manual and powered water-fed poles in the marketplace. Many residential cleaners use these tools when they win a C&I or utility-scale cleaning job due to the relatively low CAPEX.

Source: https://sola-tecs.com/en, https://cwcsupplyusa.com/

Versatility - Very versatile

Accessibility / Setup - Very easy

Logistics - Van or Truck

Work Type - Unskilled

Power Source & Power Source Management - Battery

Water Consumption - High end

Productivity Levels - Low End

Machine Maintenance - Low End

Carbon Footprint - Battery Based

System CapEx - Low end

System OpEx - Low end

Manual Lift and Shift

This system is powered by 1 or 2 people pushing the robot down an array. It is typically used in places where the labor rates are on the lower end.

Source: SCM Solar

Versatility - Low end. The width of the machine defines the installation you can clean. Not applicable for inclined rooftop and more.

Accessibility / Setup - Relatively easy setup.

Logistics - Van, Truck, or pickup truck + trailer

Work Type - Unskilled with minor training

Power Source & Power Source Management - Electrical, long power lines have to be managed.

Water Consumption - Low end

Productivity Levels - Low end

Machine Maintenance - Brushes need to be replaced.

Carbon Footprint - Electrical but in many situations, you need a generator to power them.

System CapEx - Mid-range

System OpEx - Mid-range

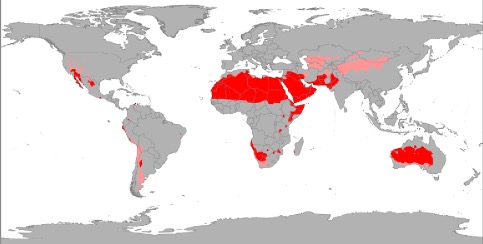

Dry Cleaning

Dry cleaning only is recommended in these parts of the world. All the systems above also function as dry cleaning options. Below are listed the solar panel cleaning machinery that is only dry cleaning.

Source: https://www.researchgate.net/publication/354666199_Water-free_automated_solar-panel_cleaning

Fixed Slider with Docking Station - 100% Dry cleaning

The solar-powered fixed slider with docking station is a system typically used where PV soiling rates are extremely high and the installation is very remote. Conceptually it is very different from the systems seen above because you have one robot per array that is fixed and housed in a docking station. The robot can be programmed to clean at a certain time or remotely activated.

Source: Aegeus Technologies

Versatility - Not versatile. Makes sense in areas where PV soiling rates are high, humidity is virtually nonexistent, and utility-scale installations that are very remote.

Accessibility / Setup - The installation is usually designed and built out with this solution.

Logistics - one-time setup and logistics

Work Type - basically no labor after setup

Power Source & Power Source Management - Solar powered.

Water Consumption - 0

Productivity Levels - high-end

Machine Maintenance - high-end due to the high volume of machines per installation

Carbon Footprint - Solar powered and battery-powered

System CapEx - Very high. One robot per row array is required for this system to work.

System OpEx - High due to a large number of assets that have to be maintained

The success of choosing the right machinery is directly correlated to your understanding of the cleaning challenges you have to face in the present and in the future. Analyze the characteristics of each of your installations and plan accordingly. Understanding the solar panel cleaning machinery options will help you make a better decision.

Carla Dawson is the cofounder of Relysm, a solar panel cleaning consulting company based in Spain and the USA. Relysm engineers and architects are dedicated to designing optimum solar panel cleaning systems for solar asset owners and more. Carla has a BS in Industrial and Systems Engineering, and an MBA.

Carla Dawson is the cofounder of Relysm, a solar panel cleaning consulting company based in Spain and the USA. Relysm engineers and architects are dedicated to designing optimum solar panel cleaning systems for solar asset owners and more. Carla has a BS in Industrial and Systems Engineering, and an MBA.

Relysm | www.relysm.com

Author: Carla Dawson

Volume: 2022 March/April

.png?r=3297)