7 Tips to Reduce Time, Money, and Stress: Practical advice for utility-scale PV + BESS control system development and commissioning

One of the keys to unlocking the full potential of renewable energy is battery energy storage. Nowhere is this more evident than when coupled with photo-voltaic (PV) power plants. According to the U.S. Energy Information Administration, battery energy storage capacity tripled in 2021. Additionally, 93 percent of the battery capacity added last year was co-located with solar.

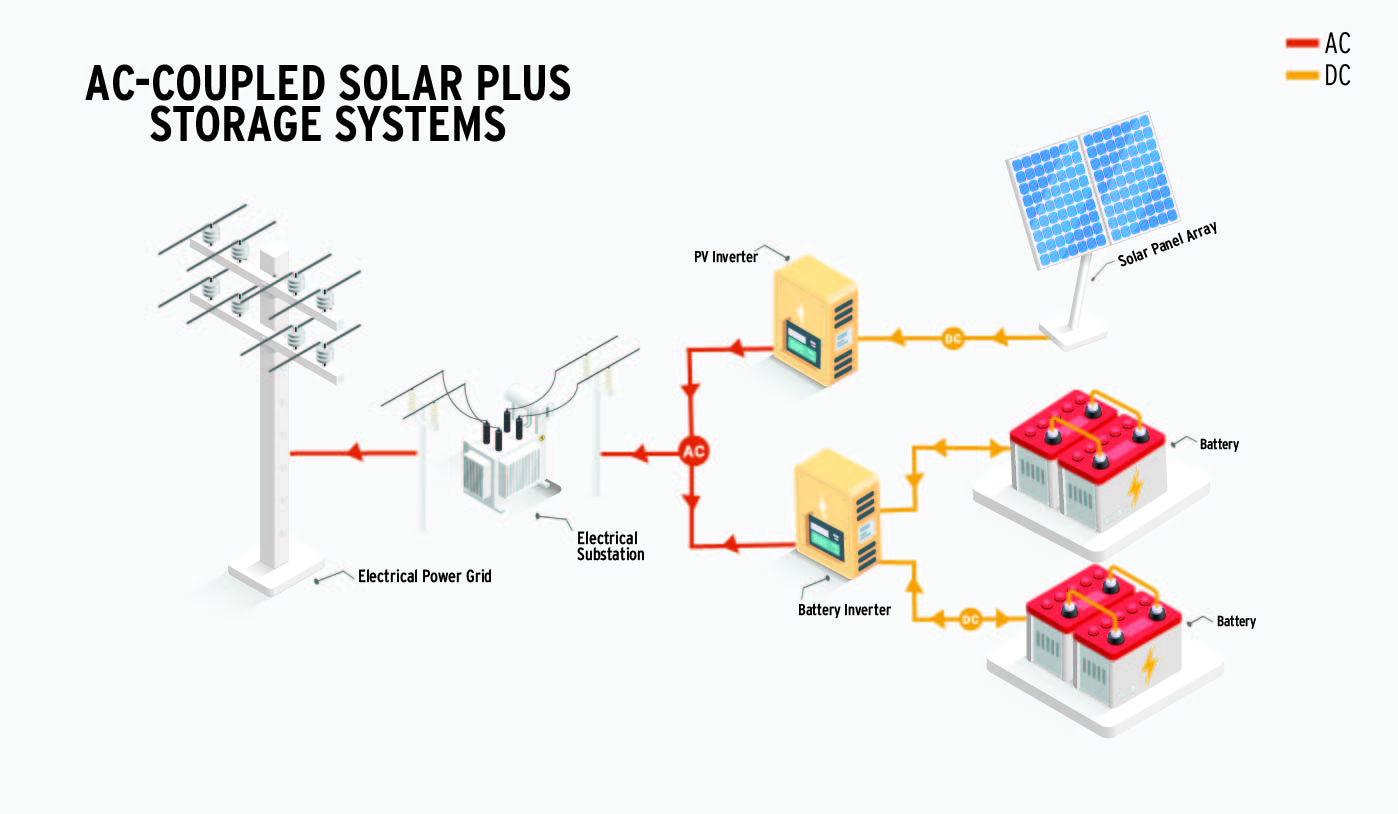

It’s said that the only thing better than learning from your own mistakes is learning from someone else’s. There are two primary architectures for coupling BESS with PV: DC-coupled and AC-coupled. The following tips are based on lessons learned from developing and commissioning AC-coupled BESS and PV projects (Figure 1).

Figure 1 – AC Coupled BESS and PV

Tip #1: A Control System Functional Specifications is a Must

Generally, the project design package will include a detailed design for the substation, the PV array, the BESS lineups, and communications for control and SCADA. Projects with the highest success levels will also include a comprehensive control system functional specification, a document detailing the control system's capabilities, constraints, appearance, and user interaction.

The requirements for how the controls system will meet interconnection agreement (IA) and power purchase agreement (PPA) power plant requirements will be contained within the specification. Using the functional specification, the system integrator develops a detailed plant control narrative (PCN) and SCADA design, along with an itemized quality assurance checklist. System integrators that begin design and development without a functional specification will risk significant rework and project delays during system commissioning.

Tip #2: Require a Factory Integration Test (FIT) for New Products

Lack of product maturity and market volatility represents a significant risk to system integrators. Executing a factory integration test (FIT) prior to, or within the project, is one way to mitigate this risk. Typically, the owner and engineer of record participate in the FIT. As part of the FIT, the system integrator will configure the SCADA system's power plant controller and elements to verify the factory's functionality and performance.

A detailed test procedure is developed and agreed to in advance by all parties. The system integrator and manufacturer conduct and document the test, making adjustments along the way. It's important to document the equipment firmware revision at the end of the test, as any modifications moving forward can significantly impact future commissioning. The FIT is also the perfect opportunity for the system integrator to develop a relationship with support personnel, thus, streamlining future support.

Tip #3: Pin Down Electrical Metering Early in Development

Electrical metering is critical to the operation of any power plant – for both revenue tracking purposes, and providing the primary feedback variable for power plant control. Therefore, most designs include both primary and backup meters. In addition, virtual (calculated) meters may be required to satisfy the functional requirements. Additional considerations include using compensated or un-compensated values within the control algorithm.

Meters must be configured appropriately for voltage, current, and power flow direction. Furthermore, the correct assignment of analog outputs is important if hardwired inputs to the control system are required. Substation end-to-end testing is the ideal time to test and verify metering, as the engineer of record is typically on-site, and issues can be quickly resolved and easily documented.

Tip #4: Don’t Forget About the Mechanical Systems

PV+BESS are predominantly considered electrical systems, but your power plant will operate at less than optimal if mechanical systems are not properly managed, operated, and maintained. For PV, this can include the tracker system. For BESS, this includes the container systems for climate control, fire suppression, and access. The system integrator should refer to the control system functional specification to determine the systems and points that need to be integrated for the mechanical systems.

Most of these systems will be provided as packaged systems. For systems that do not come with packaged controls, the system integrator may need to account for the control within the control system design and development. Like the electrical systems, the mechanical systems must be thoroughly commissioned. Tracker systems not operating properly will result in reduced system output; problematic BESS mechanical systems result in higher-than-expected auxiliary loads reducing battery system capacity. Lastly, don’t forget to test the fire suppression system, as this system is important to suppressing a thermal runaway condition.

Tip #5: Verify Networks Before Hot Commissioning of Field Equipment

This tip sounds intuitive, but it should be a high priority on the control system pre-startup checklist. Network cabling integrity is easy to confirm, and can significantly reduce time wasted isolating and troubleshooting communication issues, especially considering that most utility-scale solar farms are a minimum of 200 acres, with the largest plants in the 1000s. Reducing the time in the field, not to mention exposure to environmental conditions and safety hazards in extreme locations, will lead to a more positive commissioning experience.

Recommend that the data-comm installer provide reports as evidence that cabling has been terminated and tested. Get to know the field team that is performing cold and hot commissioning of the equipment; they can save you time in the field if they are able to assist with verifying equipment communications.

Tip #6: Take Advantage of Early Power Plant Testing

Most plant controls can be tested with only partial operation. Electrical systems are generally organized based on substation feeders. Start plant control testing when the first feeders come on-line. This approach allows more time for verification, documentation, and remediation. Resources are more readily available at this point in the commissioning process. Additionally, starting early allows system integrators to work around unpredictable conditions, such as equipment failures or weather conditions.

If you do choose to wait until the end, be prepared to endure significant pressure. Once all equipment is online, all priorities will be focused on the commercial operation date (COD) milestone. Remember, time is money!

Tip #7: Use High-Speed Trending when Tuning Control Loops

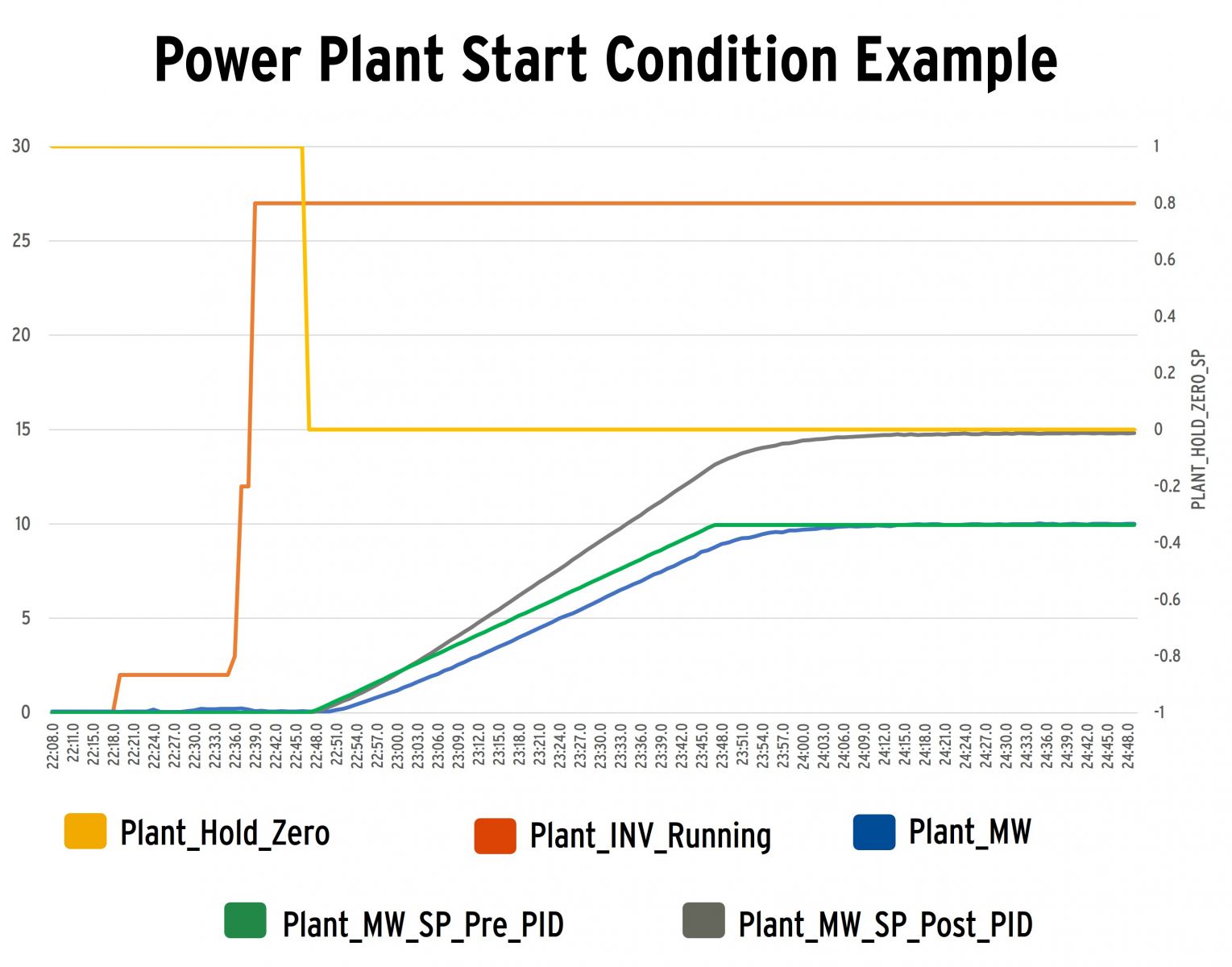

During power plant testing, high-resolution data analysis is required to understand and tune control. Avoid the temptation to use the SCADA system historian. The issue with using SCADA is the latency along with the data resolution. Instead, use the high-speed trending capability of the automation controller for optimal results. Figure 2 shows an example of a plot for verifying the startup of a PV plant.

Figure 2 – Use High Resolution Trending to Tune Controls

Allan Evora is a leading expert in control systems integration, and has worked in every capacity of the power and energy management project lifecycle. With over 25+ years of industry experience, he worked at the Boeing Company and General Electric before establishing Affinity Energy in Charlotte, NC in 2002. Affinity Energy is a turnkey systems integrator that designs, programs, installs, commissions, and supports renewable energy systems and mission critical infrastructure systems, such as emergency power supply systems and central energy plants.

Affinity Energy | affinityenergy.com

Author: Allan D. Evora

Volume: 2022 September/October

.png?r=2280)