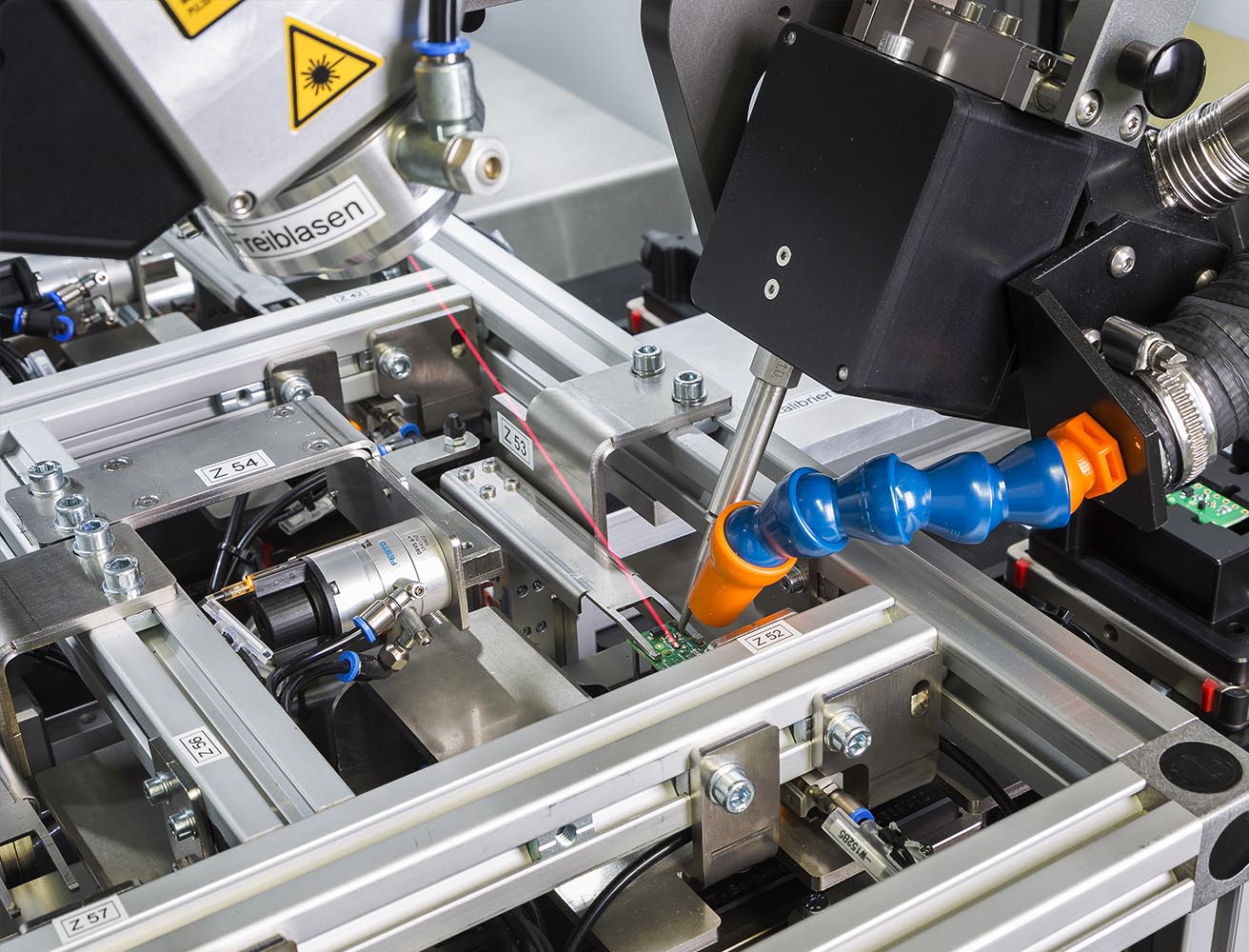

Miniaturization through controlled laser soldering

EUTECT GmbH has been using diode lasers for its customized soldering systems for years to provide pinpoint-accurate, fast, and definable soldering. Laser sources are subdivided into various categories; gas, solid, and semiconductor lasers are differentiated. The laser-active medium is important in this connection, since it determines the wavelength as well as the radiation quality. Radiation quality is decisive for the laser's energy density and ability to focus. Medium or low energy densities are needed during laser soldering. In this connection, the solder joints must be efficiently and homogeneously heated without scorching the material. Miniaturization is allowing solder joints are becoming ever smaller. They inhabit ranges from <200 μm to a few millimetres. The diode laser's output power is thus easy to regulate. The power can be smoothly adjusted into the kilohertz range, whereby the laser can react quickly to energy fluctuations. An additional advantage is radiation focusing, which puts the laser in a position to solder 180 μm solder joints. Focusing with fixed focal width limits energy input locally and with pinpoint accuracy, thereby enabling reduced thermal load on the components in the immediate vicinity. The temperature-time curve is decisively important during the entire soldering process. The diode laser can be controlled according to a prescribed curve. Among other things, a non-contact temperature-measurement system, which regulates heat input relative to process- and product-specific specifications, can be used for this. The system records all process changes, which are retrievable for quality-assurance measures. Combined with the likewise adjustable wire feed, the customer obtains a system that guarantees reproducible solder quantities and connections.

EUTECT GmbH has been using diode lasers for its customized soldering systems for years to provide pinpoint-accurate, fast, and definable soldering. Laser sources are subdivided into various categories; gas, solid, and semiconductor lasers are differentiated. The laser-active medium is important in this connection, since it determines the wavelength as well as the radiation quality. Radiation quality is decisive for the laser's energy density and ability to focus. Medium or low energy densities are needed during laser soldering. In this connection, the solder joints must be efficiently and homogeneously heated without scorching the material. Miniaturization is allowing solder joints are becoming ever smaller. They inhabit ranges from <200 μm to a few millimetres. The diode laser's output power is thus easy to regulate. The power can be smoothly adjusted into the kilohertz range, whereby the laser can react quickly to energy fluctuations. An additional advantage is radiation focusing, which puts the laser in a position to solder 180 μm solder joints. Focusing with fixed focal width limits energy input locally and with pinpoint accuracy, thereby enabling reduced thermal load on the components in the immediate vicinity. The temperature-time curve is decisively important during the entire soldering process. The diode laser can be controlled according to a prescribed curve. Among other things, a non-contact temperature-measurement system, which regulates heat input relative to process- and product-specific specifications, can be used for this. The system records all process changes, which are retrievable for quality-assurance measures. Combined with the likewise adjustable wire feed, the customer obtains a system that guarantees reproducible solder quantities and connections.

EUTECT GmbH | www.eutect.de

Volume: 2017 November/December

.jpg?r=8802)