Power Grid Quality Monitoring Guarantees Reliable and Efficient Power Supply

The need for reliable, high-quality electricity has never been greater now the grid is highly dependent on getting its supply from multiple sources. Power grid quality monitoring increasingly plays a significant role in ensuring that electricity arrives at homes, businesses, and industries. This article highlights the growing demand for real-time power quality monitoring and the need for systems protection considerations in hardware design to ensure that data derived is both accurate, consistent, and shielded from cyber threats.

When power quality drops, consumers can be faced with anything from failing electronics to interrupted services. In worst-case scenarios, bad power quality even pose health hazards for people dependent upon medical equipment.

Voltage instability is also a threat to the grid as a whole. Whether dips (sags) or spikes (surges), these can cause errant issues on vital pieces of equipment such as turbines, inverters, and transformers. The smallest variation in frequency will disrupt the sync of power generation units, leading to inefficiency or worse, generator loss. They can even create harmonic distortions. Distortions occur whenever non-linear loads, which may be the consequence of the operation of heavy machinery or electronics, produce electrical noise that can contribute to overheating, shorter equipment lifetimes, or expensive repair bills.

For IPPs, poor power quality does not start and end with the threat of failing equipment; ultimately, it can affect their right to supply. This is because IPPs are integrated into public transmission and distribution networks (otherwise known as the power grid) who impose stiff performance standards upon them so the system is kept stable and stable. When IPPs don't pass muster with these requirements, it is no longer just a temporary pain but can bring about penalties, downtime, or loss of relation with grid operators.

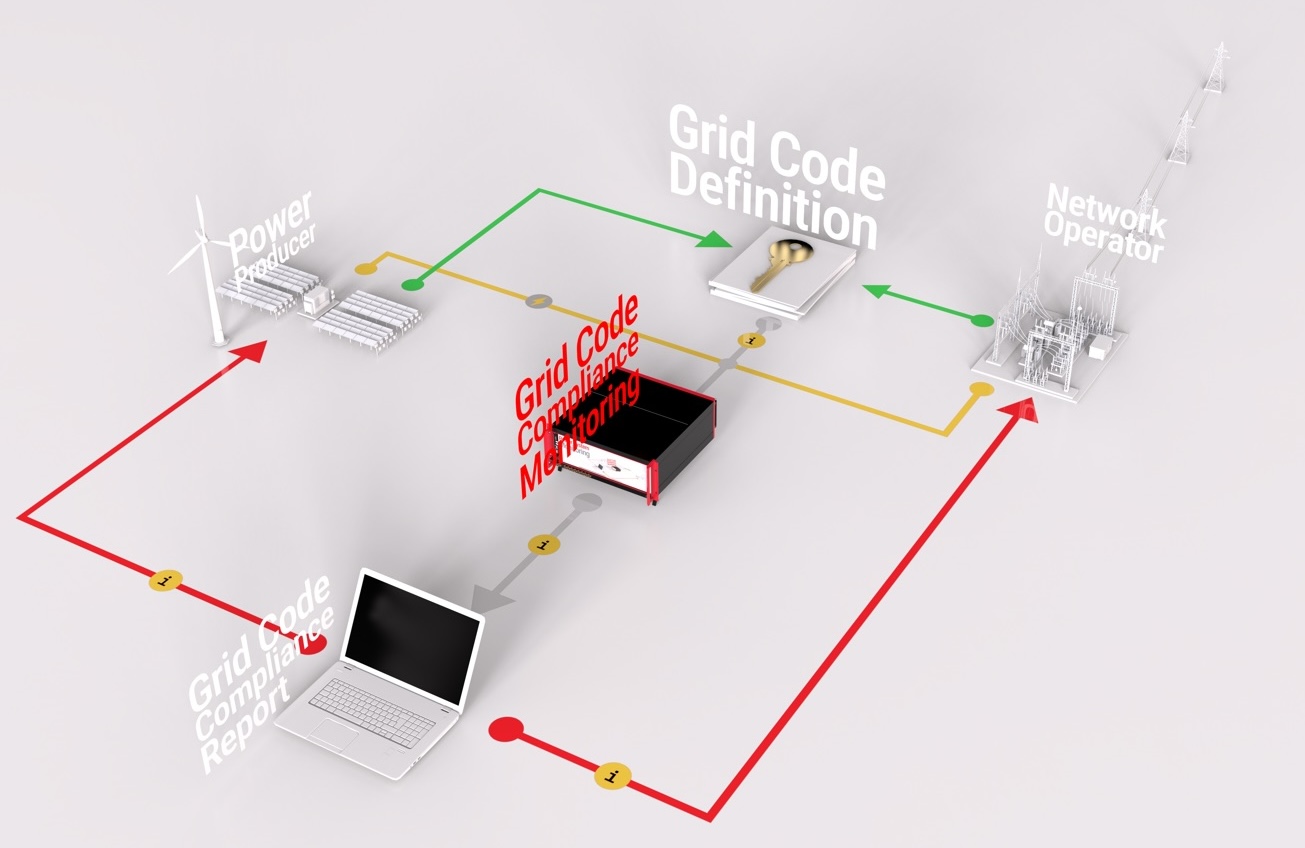

Quality monitoring and systems protection

To avoid the above problems and ensure reliable power quality, specialized companies design monitoring systems for grid performance, ensuring IPPs remain in compliance with the relevant grid codes. Their monitoring applications are usually built on board-to-board connected printed circuit boards (PCBs), safely housed in enclosures that also provide onboard power supplies for continuous and dependable monitoring of IPPs' generated power, avoiding interruptions before they occur. But it's not all about monitoring the power; it is also protecting the delicate electrical and electronic equipment that makes up the heart of the quality monitoring solution.

An important challenge in the design of reliable power monitoring tools is adequate electronics cooling. If equipment isn't cooled correctly, it can lead to complete hardware failure. Integrating cooling systems like fan speed control and heat dissipation are needed to ensure electronics do not get overheated and maintain operations.

Other design points to address are cyber-attack prevention and electromagnetic interference (EMI). Cyber-attacks today are a real threat to the power grid. In 2024, Check Point Research counted 1,162 cyberattack attacks on utilities, up 70 percent against the same six months a year ago. EMI shielding prevents the system from electric noise that may interfere with its operation. All these issues have to be addressed as part of overall systems protection design. The risks are just too great to ignore. The fact is that most power grid quality monitoring companies do not always have extensive in-house expertise to deal with mechanical, thermal management, and EMI design requirements. Therefore, calling in systems protection knowhow from third party companies is not an abundant luxury.

Designing rugged, reliable enclosures that shield against threats such as heat and electromagnetic interference (EMI) requires the right technical know-how. In working with systems protection suppliers, power quality monitoring application developers can leverage enclosure design expertise to ensure their systems comply with stringent requirements necessary for today’s grid.

An electrified and connected world

As we push forward toward a more electrified and interconnected future, the task of monitoring power grid quality will become progressively more critical. Backplane and custom-designed housing systems must be capable of meeting that challenge. Whether handling heat, delivering power, or protecting against physical stress, these systems will need to be tough and resilient. Grid security serves to benefit consumers and IPPs equally. Engineers will have to focus on cooling, system integrity, and power distribution to make these systems effective in order to make them function safely and efficiently. It is only when all of these work together in harmony that we can be more stable and confident of an actual secure, reliable, and efficient energy future.

Edwin de Boer is nVent’s Strategic Market Manager for Battery Storage and Renewable Energy Systems Applications. A hands-on industry expert, he is focused on delivering customer excellence by driving sustainable change and supporting best-in-class product innovations. With over 20 years of industry knowledge, Edwin is a trusted business partner helping organizations protect their mission-critical business applications. Before joining nVent, he held various roles in international technology and electrical companies such as Raritan and Legrand.

Edwin de Boer is nVent’s Strategic Market Manager for Battery Storage and Renewable Energy Systems Applications. A hands-on industry expert, he is focused on delivering customer excellence by driving sustainable change and supporting best-in-class product innovations. With over 20 years of industry knowledge, Edwin is a trusted business partner helping organizations protect their mission-critical business applications. Before joining nVent, he held various roles in international technology and electrical companies such as Raritan and Legrand.

nVent | www.nvent.com

Author: Edwin de Boer