Leveraging GPS to Overcome Challenges in Solar Site Construction

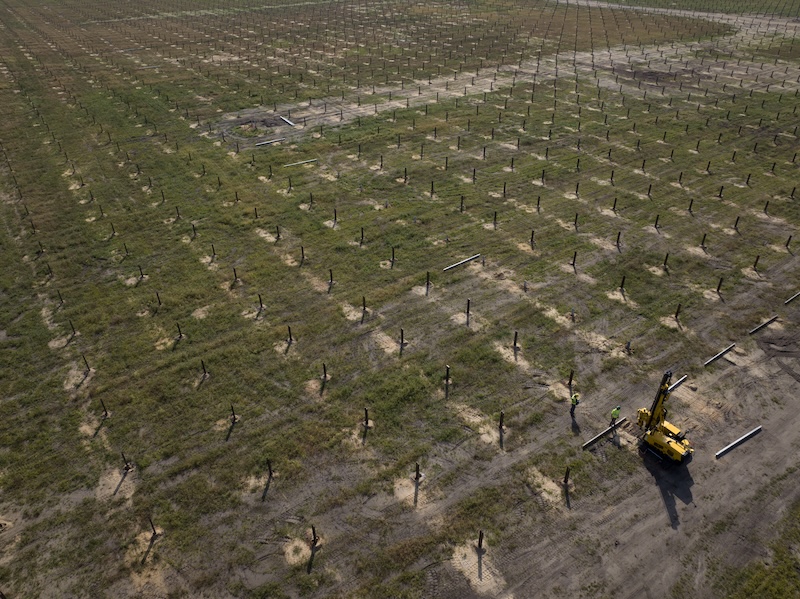

Difficult terrain presents significant obstacles to maintaining productivity on solar construction sites. Solar farms are rarely built on perfectly level ground; to control costs, many projects aim to minimize site preparation. This creates real challenges for surveying crews who have traditionally staked solar projects to identify pile locations. Many crews are adopting GPS-guided pile drivers that offer greater precision and efficiency, even in remote or rugged environments, to overcome these obstacles.

At the same time, contractors are grappling with workforce shortages, evolving project scopes and tight timelines, pressures that strain productivity even under the best conditions. These challenges are prompting many to rethink traditional workflows and look for more strategic ways to manage equipment and labor.

Maximizing productivity through technology and team support

In response, contractors are seeking out practical solutions that combine equipment innovation with hands-on jobsite support. They’re not just looking for new tools, they’re working closely with partners who understand solar-specific workflows and can help integrate GPS solutions directly into everyday operations. These partnerships help crews adopt and apply GPS technology more effectively, leading to faster startup times, reduced manual layout work, and fewer delays onsite. In many cases, this collaboration helps bridge the gap between emerging technology and field-level execution, accelerating the learning curve for crews while helping contractors hit performance targets with greater consistency.

This widespread collaboration has played a major role in accelerating the adoption of GPS in renewable energy markets.

Adopting proven technology

Although it has been widely used in various construction applications for years, the integration of GPS technology is an emerging trend in renewable energy construction. Industry experts have recognized over time that many niche markets and specialized equipment could benefit from the GPS technology commonly used on heavy machinery such as dozers, excavators, and haul trucks.

A collaborative effort between industry partners working closely with contractors has made this a reality. Given the repetitive nature of solar installation activities, implementing GPS technology is highly advantageous.

Designing machinery to integrate with technology

Designing machinery to integrate with technology

Leading equipment manufacturers excel in developing machinery with integrated GPS technology. Such equipment is designed from the ground up to accommodate GPS integration, offering significant advantages for companies seeking technological solutions to address skilled labor shortages.

Manufacturers consider how GPS integration will function by actively seeking feedback from contractors, dealers, and GPS providers. This holistic approach helps align equipment design with real-world jobsite demands, simplifying operations and supporting productivity in the field.

The integration of GPS into pile drivers has already significantly helped control solar surveying costs. The next advancement involves automating common pile installation tasks. Machines equipped with point-to-point (PTP) systems minimize the number of manual steps required for machine positioning and alignment, reducing operator input steps per cycle from 11 to 4.

GPS systems are typically installed at dealerships emphasizing the importance of choosing knowledgeable and capable partners. Progressive industry partners deliver an integrated and intuitive operator experience further enhancing efficiency.

Addressing site survey challenges with GPS technology

One of the most immediate ways contractors are applying GPS technology is in-site surveying. This traditionally time-consuming task poses significant challenges in difficult terrain. Surveyors typically place physical markers like feathers, flags, or stakes into the ground, which can significantly raise labor costs, especially on large-scale solar projects.

GPS technology provides an effective solution by eliminating the need for physical markers, string lines for orientation, and rotating lasers for elevation. This transition to GPS not only helps reduce labor costs but also streamlines the construction process. One solar contractor reported saving over $1.3 million in surveying costs on a single project by integrating pile drivers equipped with GPS technology. This investment delivered immediate benefits and continues to yield cost savings for future projects.

Preparing contractors for future solar construction

As the solar construction industry continues to evolve, the adoption of technologies like GPS coupled with specialized training is proving transformative. Contractors guided by experienced technology providers and dealers discover innovative methods to enhance efficiency and reduce costs. GPS technology integrated into operations the solar construction industry is well-positioned to overcome labor shortage challenges and other hurdles.

Technology serves as a valuable tool that helps contractors perform their jobs more effectively and efficiently. Contractors consistently report improved job performance and productivity after adopting these technological solutions. This positive impact continually reinforces the value of technological advancements as the industry evolves.

Solar construction projects will continue encountering obstacles related to challenging terrain. However, by adopting GPS-guided equipment, collaborating with specialized equipment providers, and focusing on efficient crew coordination, contractors can better navigate these challenges. Effectively combining technology with teamwork allows contractors to consistently achieve high-quality outcomes regardless of the jobsite environment.

As solar markets continue expanding contractors who proactively adopt GPS-guided pile drivers and specialized equipment are better positioned to handle industry growth. Quickly adapting to new technologies and efficient methods is critical for contractors aiming to deliver successful solar projects especially when faced with challenging conditions.

Kipp Ulferts is Corporate Accounts Manager at Vermeer Corporation, which designs and builds machines to equip customers to do more across a diverse group of important markets including underground construction, infrastructure, surface mining, tree care, environmental and agriculture.

Vermeer Corporation | www.vermeer.com

Author: Kipp Ulferts

Volume: 2025 July/August

.jpg?r=1379)