Volt Carbon Technologies Releases Test Results for Its High Energy Density Lithium (Li)-Metal Iron Phosphate Battery and Provides Operational Update

Volt Carbon Technologies Inc. (TSXV: VCT) (OTCQB: TORVF) ("Volt Carbon" or the "Company") is pleased to announce the release of its initial test results for its exclusive Lithium Iron Phosphate battery (LFP) employing its internally developed electrolyte. These batteries were manufactured at Volt Carbon's subsidiary, Solid UltraBattery's ("SUB") facility, situated in Guelph, Ontario. These recent findings mark a significant step forward in Solid UltraBattery's advancement of high-energy LFP technology, as initially outlined in the Company's roadmap which was disclosed to the public on July 24, 2023.

Background

The increasing popularity of Lithium Iron Phosphate (LFP) arises from its cost-effectiveness compared to Lithium Nickel Cobalt Manganese Oxide (NCM), achieved by substituting the NCM cathode with an LFP cathode. Traditionally, a significant drawback has been LFP's limited energy density, impacting the driving range of electric vehicles (EVs). Numerous articles in literature confirm LFP's drawbacks, including a 2023 Forbes Magazine piece titled "Lithium Iron Phosphate Set To Be The Next Big Thing In EV Batteries," which notes a 30-40% lower energy density of LFP compared to NCM, along with the safety advantages of the LFP cathode over NCM in the event of a battery fire. A link to this article can be found at https://www.forbes.com/sites/samabuelsamid/2023/08/16/lithium-iron-phosphate-set-to-be-the-next-big-thing-in-ev-batteries/?sh=340446717515.

Highlights

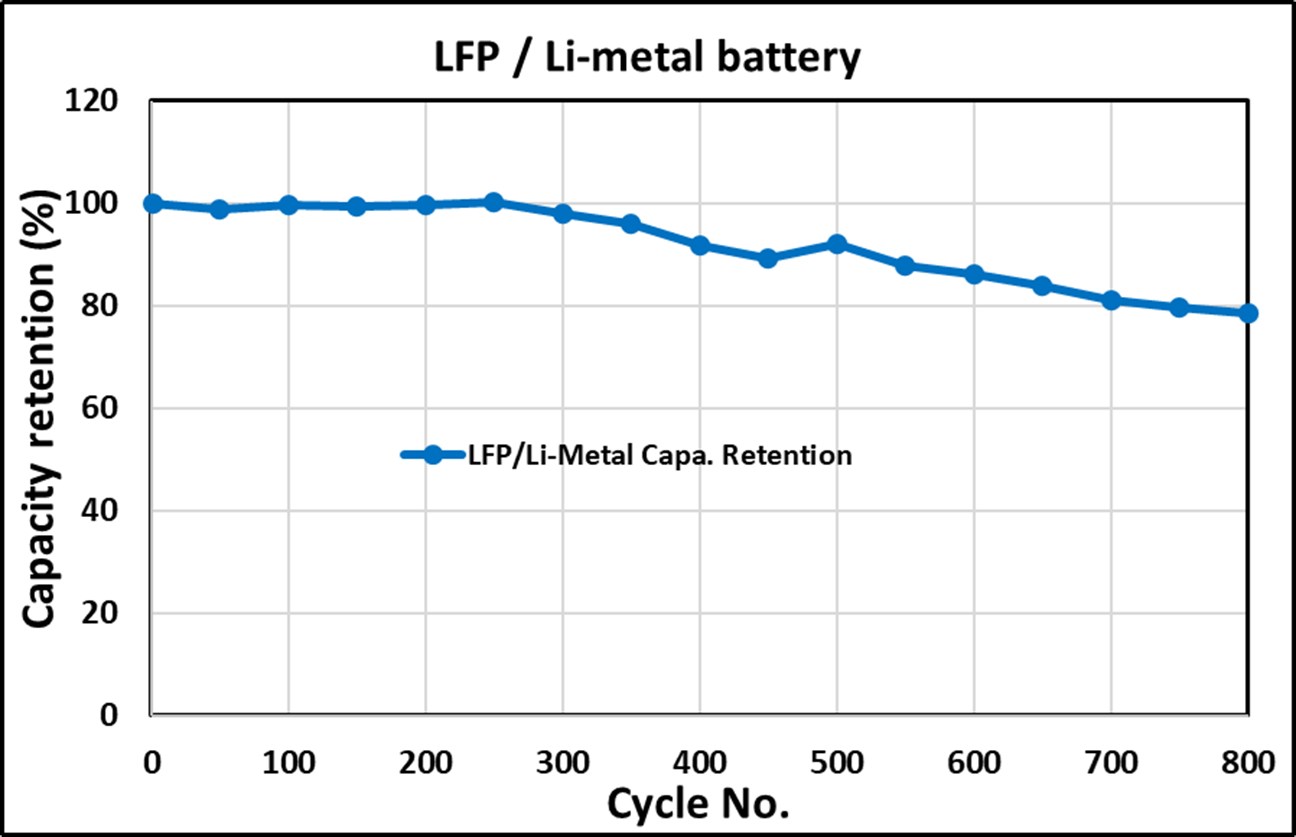

In response to the energy density limitations of LFP, along with its acknowledged safety advantages over NCM, SUB has been working on a lithium (Li)-metal LFP battery to improve energy density. Management believes they have achieved an industry-leading 280Wh/kg for this cathode type. This technology has the potential to significantly impact battery competitiveness for electric vehicles and battery-powered devices by offering cost-effective alternatives through the removal of nickel and cobalt. Recent testing by SUB demonstrates that LFP/Li-metal battery coin cells have endured 800 cycles while maintaining 78.5% of their capacity (refer to Figure 1), marking a notable milestone in LFP/Li-metal battery technology advancement.

Fig. 1: Li-Metal LFP Coin Cell, Charge/Discharge data, 2.9-3.7V, C/3, 25 °C

Next Steps

These test outcomes reaffirm the Company's goal to surpass 800 cycles and achieve an 80% capacity threshold by the end of 2024 with Lithium (Li)-metal Iron Phosphate battery technologies. Additionally, the Company remains steadfast in following its technology roadmap, initially released on July 24, 2023 (refer to Figure 2 below), which outlines its strategic trajectory for lithium-ion battery product advancement until 2030.

Update on Graphite Development

Since the start of 2024, the Company has enhanced its Guelph prototype battery lab with more fabrication and cycle testing equipment, boosting its capacity to build and test pouch and coin cells. This new equipment will help in development of battery-grade anodes processed from Volt Carbon's Scarborough facility. More test results from the battery anode testing will be published in the coming months.

.jpg)

Fig. 2: Volt Carbon's Product Roadmap

V-Bond Lee, the Company's CEO and President, expressed his satisfaction, stating, "I'm thrilled with these great results; hitting 800 cycles is a new milestone for the Company. Our ongoing investment in talent and equipment is guiding Solid UltraBattery towards an exciting journey in energy storage development. We're fully committed to advancing and bringing our technology to market."

Volt Carbon | www.voltcarbontech.com