Factory Finished

Energy generation and consumption are changing rapidly around the globe. As renewable generation merges with energy storage technologies, new power architectures must be applied. Integrators face significant challenges and pitfalls while responding to the growing need for storage. Many of these pitfalls are rooted in not having the proper system architecture to support the goals of the project. Choosing a power architecture that best aligns with the energy needs, demands, and markets of the future, is critical to deploying successful clean energy projects.

The architecture of the hardware behind any energy storage installation heavily impacts both the real and soft costs of how a business operates. It also affects the cost basis of the project, beyond the upfront purchase price. Integrators factor in these cost implications in the configuration and project sizing phase - before they are even awarded a contract - which can lead to substantial losses/customer acquisition costs if they fail to win the project. System sizing, warranty assumptions, availability guarantees, and service models all add to the cost basis, which the integrator passes on to the end user. Picking an architecture that lowers the cost of all these factors is critical to achieving the lowest possible installed system cost, at the highest reliability and performance levels.

The architecture of the hardware behind any energy storage installation heavily impacts both the real and soft costs of how a business operates. It also affects the cost basis of the project, beyond the upfront purchase price. Integrators factor in these cost implications in the configuration and project sizing phase - before they are even awarded a contract - which can lead to substantial losses/customer acquisition costs if they fail to win the project. System sizing, warranty assumptions, availability guarantees, and service models all add to the cost basis, which the integrator passes on to the end user. Picking an architecture that lowers the cost of all these factors is critical to achieving the lowest possible installed system cost, at the highest reliability and performance levels.

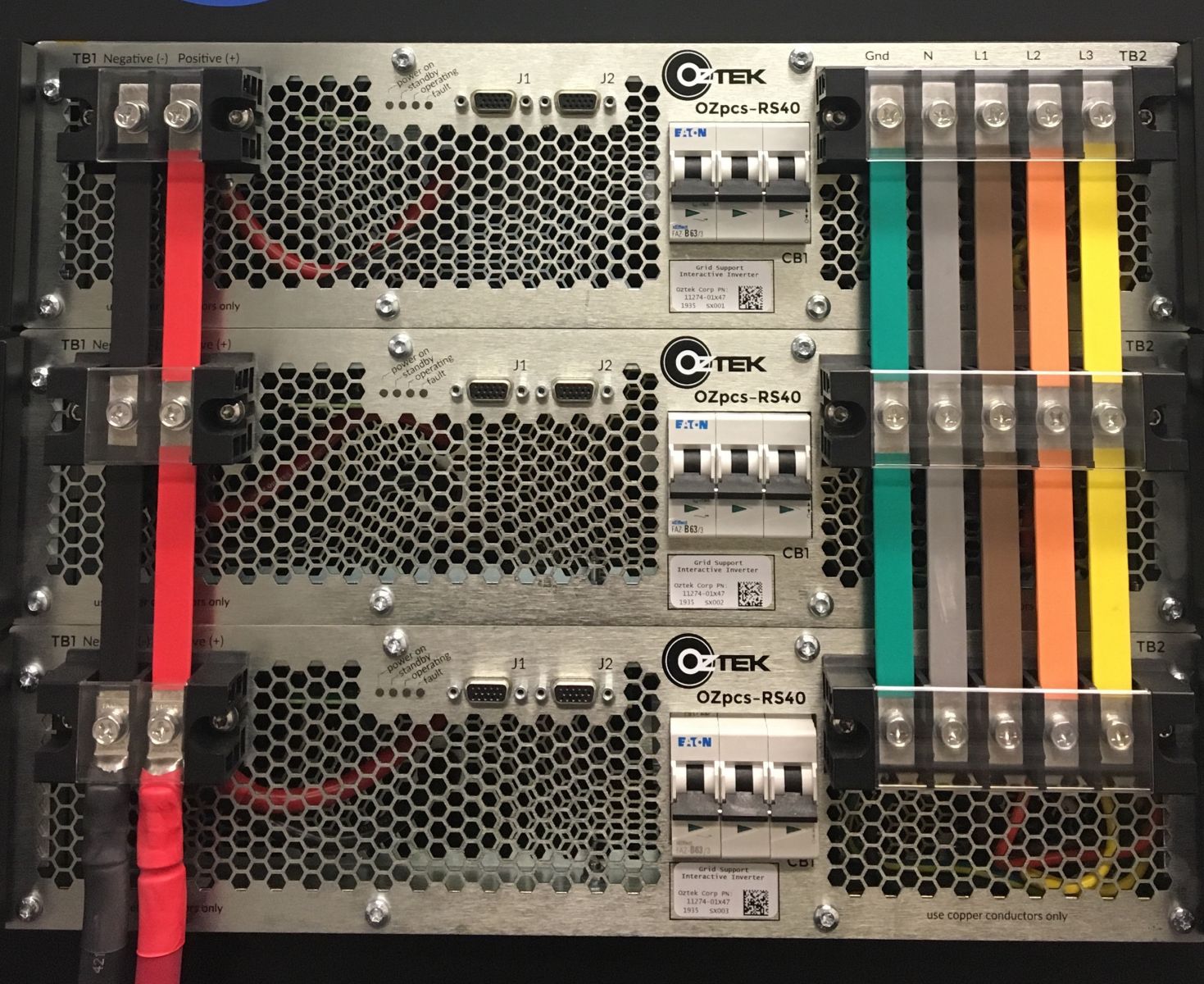

Modular architectures allow manufactures to quote lower costs for warranty support, lower costs for capacity guarantees, lower costs for availability guarantees, and (above all) lower production costs, by creating a factory finished product. This is achieved not only by increasing the predictability of your cost basis, but also by shifting where labor is performed (factory vs field.). Smaller sized PCS products can be better aligned within the supply chain, and be tested as complete higher-level assemblies before they ship.

Lowering the cost of maintaining and augmenting a system allows for a lower up-front cost because less money needs to be reserved for future expenses. The result? Total cost of ownership is not limited to ongoing operational expenses, and DOES translate into the upfront cost of deploying an energy storage system.

When the time comes to add capacity, a storage system that has isolated its batteries (with either AC conversion or DC conversion at the string level) will be able to add energy with ease. Mismatched impedance, short circuit calculations, differences in capacity, and differences in technology, are all masked and managed by having this one degree of separation between the batteries. The control system can look at each string and maximize its contribution, such that each string reaches "empty" at the same point in time, maximizing run time. Smart integrators already take this approach.

120KW of bi-directional grid connected UL1741SA approved power conversion. Each unit 40KW/KVA, three in parallel, total of 13" vertical in standard 19" cabinet.

It is interesting to note that data center computing, telco power systems, and even solar industries have chosen to use modular solutions as the industry standard. How can they all afford modularity? As it turns out, it's more cost effective to manage a limited number of building blocks, from which a variety of systems can be built. It also offers the flexibility, availability, expandability (~augmentation), and manageability of the "Internet of Things" (IoT) hardware you expect in today's technology environment. If a product fails, just put it in a box and send it back; and yes, it can be that easy. How would a data center function if it had to wait for a qualified technician to fly half way around the world to look at a server failure? That kind of inefficiency just wouldn't work. Equipment on the grid should be expected to be as reliable as data center equipment, with the same level of availability, uptime, serviceability, and low MTTR.

The ability to completely manufacture and test the system as whole building blocks prior to shipping, while properly extracting and managing the energy storage capacity from each battery, is the key to achieving the lowest possible cost and the highest reliability in the industry

Given the reality of the aforementioned factors, the total installed costs of energy storage systems can be reduced by leveraging the power of the modularity. The traditional pieces of storage architecture - a battery container, a power conversion system (PCS), and a control system - all come together; it would be like driving around in a hybrid car with the battery in a trailer towed behind, and one of those travel pods from the 80's on the roof to hold the electronics. Our industry can do better. The winners in energy storage will achieve a high level of flexibility and integration that others can't match.

Greg Tremelling is VP Business Development at Oztek Corporation, which provides power conversion systems, design assistance, and engineering support with off the shelf product,s as well as semi-custom designs that build off existing product platforms.

Oztek Corporation | www.oztekcorp.com

Author: Greg Tremelling

Volume: 2019 November/December