Eliminating Risk in Battery Energy Storage Systems Through Simulation

As grid operators respond to surging energy demands driven by electrification, renewable integration and AI-powered data centers, battery energy storage systems (BESS) are playing a more critical role than ever before. But as deployment accelerates, an often-overlooked challenge continues to surface: Unmanaged thermal behavior.

For many BESS developers and site operators, thermal issues only become apparent after commissioning when declines in performance, equipment failures, or safety concerns start to emerge. With few standardized methods of evaluating BESS performance at scale, project teams are frequently forced to rely on assumptions. That’s where physics-based simulation can change the game.

Hidden threat: Heat at scale

Battery energy storage systems are designed for rapid charging and discharging, often under extreme environmental conditions. While individual units may pass factory tests, their thermal behavior changes significantly when installed in large arrays. Heat expelled from one unit can be reingested by others nearby, creating localized hotspots. Additionally, multiple units placed together can create "heat islands" that raise site-wide ambient temperatures and reduce overall system efficiency.

The root of the problem lies in the fact that most testing protocols are based on isolated containers. These do not account for key variables like prevailing wind direction, solar loading, or seasonal temperature swings, factors that significantly influence thermal behavior across an entire site.

Why simulation matters

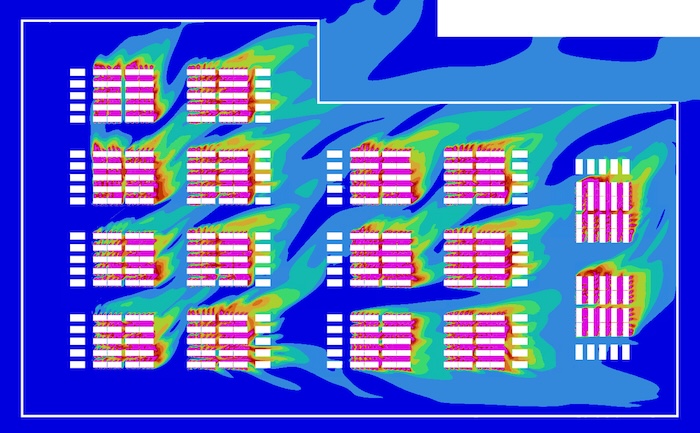

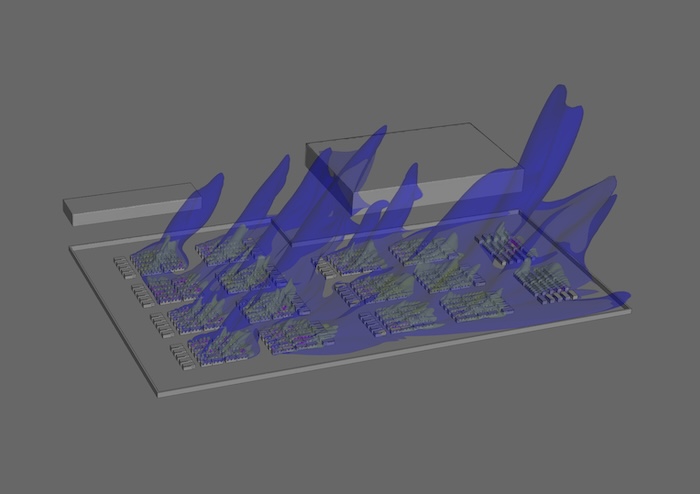

Computational Fluid Dynamics (CFD) simulation provides a robust, predictive lens into site behavior long before construction ever begins. By digitally modeling air flow, thermal interactions, and site layout, engineers can predict real-world performance under a range of operating conditions and identify high risk zones early in the design process.

These insights inform strategic decisions, from equipment spacing to louver design to ventilation and exhaust modifications, ultimately helping teams avoid costly trial-and-error in the field.

In one real-world example, a BESS installation experienced unexpected drops in performance due to hot exhaust air being drawn back into neighboring units. Using simulation, engineers pinpointed the issue and tested a design fix: 70-degree louvers that redirected exhaust flow, eliminating reingestion and restoring system efficiency. This small tweak made a multi-million-dollar difference.

Thermal risk = Financial risk

Poor thermal design doesn’t just degrade performance; it can have significant financial consequences. BESS assets are often bound by performance-based contracts, where failure to meet output targets during peak demand periods results in penalties or revenue loss. In some cases, thermal issues have required retrofits costing $2 million to $25 million, costs that could have been avoided through proactive simulation.

By identifying these issues early in the design process, site owners and developers can optimize layouts, reduce long-term maintenance and extend asset life. In an industry where projects frequently exceed hundreds of millions in capital costs, the ROI on simulation is clear.

Bridging the standards gap

One reason these risks are often missed is the lack of enforceable standards for thermal performance at the site level. While there are well established electrical and safety codes, thermal interactions between enclosures remain largely unregulated, placing the burden on developers and owners to self-validate performance.

Recognizing this, leading energy organizations are taking steps to incorporate simulation into their standard design review process. This includes thermal assessments during supplier selection, site planning, and post-installation troubleshooting.

CFD simulation also supports decarbonization goals by ensuring energy storage systems are ready to stabilize renewable supply during periods of volatility or grid congestion. Maximizing thermal performance ensures developers that their clean energy investments deliver the greatest possible value.

From risk management to strategic advantage

As the energy transition accelerates, confidence in BESS performance is paramount. Simulation doesn’t just help to avoid failure, it provides assurance. Detailed thermal analytics reports, temperature maps, and high-resolution visuals give stakeholders a clear picture of how a site will behave, helping engineers and executives to make better informed decisions. For projects that require speed, certainty and scale, integrating simulation into early-stage design is no longer optional, it’s becoming an industry imperative.

Chris Smith is Consulting Division Manager at Rand Simulation, where he leads a team of engineers focused on leveraging simulation to address thermal and mechanical risks across energy infrastructure. With a PhD in Mechanical Engineering, Chris has worked extensively with utilities, OEMs, and EPCs to improve the performance and reliability of energy systems, including BESS and substation components.

Chris Smith is Consulting Division Manager at Rand Simulation, where he leads a team of engineers focused on leveraging simulation to address thermal and mechanical risks across energy infrastructure. With a PhD in Mechanical Engineering, Chris has worked extensively with utilities, OEMs, and EPCs to improve the performance and reliability of energy systems, including BESS and substation components.

Rand Simulation | www.randsim.com

Author: Chris Smith

Volume: 2025 September/October