Beyond Monitoring: AI is redefining renewable asset management

In the rapidly expanding world of clean energy, one thing remains constant: the need for reliable, high-performing assets. Whether managing a utility-scale solar farm, a community wind project, or a mixed renewable portfolio, asset owners and operators are under increasing pressure to deliver consistent energy yield, minimize downtime, and reduce O&M overhead.

Traditionally, performance monitoring has relied on SCADA systems, OEM dashboards, and manual field inspections. While these tools provide valuable data, they often fall short in delivering actionable insights — especially when it comes to identifying subtle underperformance or preventing faults before they escalate.

Today, artificial intelligence (AI) is helping to bridge that gap. Through real-time analytics and intelligent diagnostics, AI is unlocking a new level of visibility and control for Independent Power Producers (IPPs), EPCs, O&M service providers, and clean energy installers alike.

The new era of predictive intelligence

At its core, AI-powered performance analytics are transforming how asset operators interact with their plants. Rather than waiting for an alert or reacting to a drop in generation, AI tools analyze thousands of data points in real time to detect anomalies, inefficiencies, and early warning signs — often well before traditional systems raise flags.

Whether it’s inverter drift in a solar plant, yaw misalignment in a wind turbine, or a subtle performance degradation due to environmental conditions, AI-driven diagnostics can pinpoint issues, classify them by severity, and recommend precise corrective actions.

For EPCs and installers, this translates into higher asset availability and faster troubleshooting. For IPPs and O&M firms, it means optimized portfolios, lower service costs, and stronger long-term ROI.

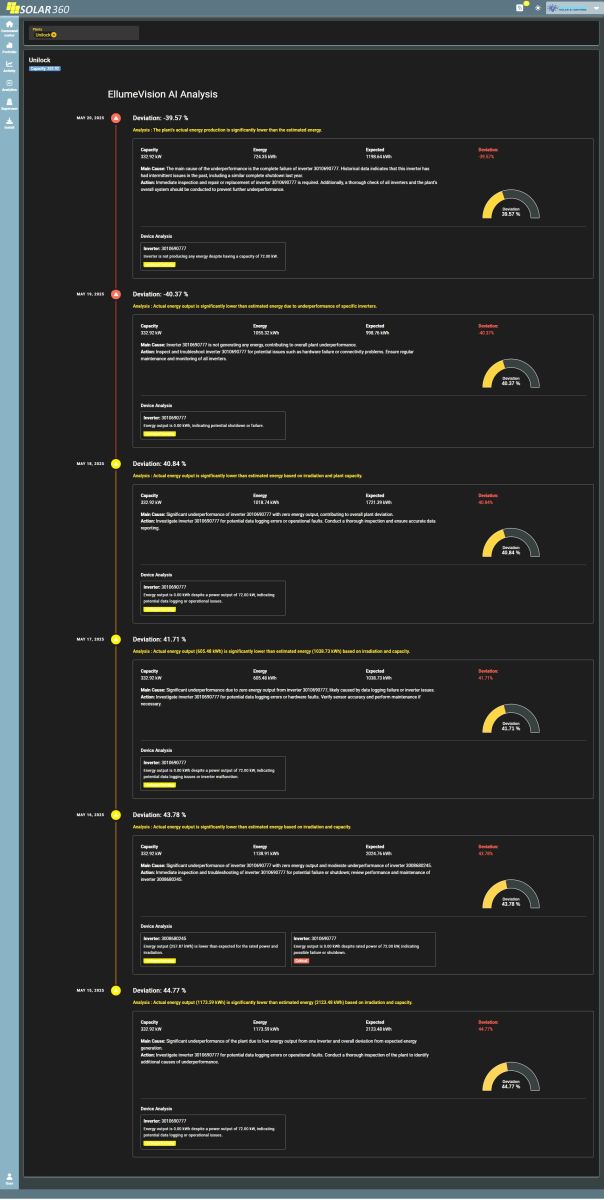

When AI saw what humans missed

At a 332 kWp solar plant in Ohio, operators experienced a sudden drop in generation performance. Daily irradiation data remained consistent, yet energy output fell to just 40 percent of the expected value. Traditional dashboards showed low yield but did not indicate clear reasons.

An AI-based performance engine processed the day’s data and flagged two inverters contributing nearly zero output. A 72 kW unit had generated 0 kWh, and another had produced just 4.44 kWh — a mere 1 percent of its expected 435 kWh. Together, these two inverters represented 144 kW, or roughly 43 percent of the plant’s capacity. Their failure alone accounted for an energy shortfall of over 866 kWh in one day.

Beyond these critical faults, the AI tool also identified partial inefficiencies in three other inverters generating between 68 and 74 percent of their expected values. These losses were likely due to temporary shading, soiling, or partial inverter malfunction — insights that would have gone unnoticed in conventional systems.

Within minutes, the tool provided a prioritized action list for the O&M team: Inspect the two failed inverters immediately (identified by their respective serial numbers) to confirm root cause and restore generation output and investigate the partially underperforming units for potential external factors or emerging degradation. This level of real-time, contextual insight enabled the plant team to act swiftly — reducing diagnostic time and preventing extended energy loss across the week.

Why AI outperforms traditional monitoring

Why AI outperforms traditional monitoring

While SCADA and inverter dashboards are essential, they often provide fragmented data that require manual interpretation. AI systems enhance this data by:

● Analyzing historical, real-time, and environmental data together

● Benchmarking actual versus expected performance with greater accuracy

● Prioritizing faults by impact, not just event frequency

● Offering recommendations based on pattern recognition and trend forecasting

This approach is especially valuable for hybrid asset portfolios, where solar and wind systems coexist and operational teams must manage diverse equipment and conditions with limited bandwidth.

Scalable intelligence for every stakeholder

AI performance tools are not limited to large utilities. They scale effectively across:

● Installers looking to offer smart O&M value-adds

● O&M providers managing multi-site service contracts

● IPP portfolios where site-level performance must be rolled up into centralized control rooms or NOCs

● Wind developers monitoring turbine behavior, availability, and power curves

Regardless of role, AI empowers teams with early visibility, precise intervention, and intelligent, data-driven decisions.

Integrating AI into existing infrastructure

One of the most compelling aspects of modern AI diagnostic tools is their flexibility. They can be deployed as standalone analytics engines, integrated with existing SCADA systems, or embedded within centralized monitoring platforms.

For EPCs and integrators, this allows for seamless incorporation into digital infrastructure without disrupting project timelines. For asset owners, it’s a lightweight layer of intelligence that enhances existing investments and ensures long-term operational excellence.

Looking forward: from insight to autonomy

As AI models continue to evolve, they are becoming more contextual, more predictive, and increasingly autonomous. In the near future, we can expect performance platforms that not only detect inefficiencies, but automatically trigger ticketing systems, dispatch maintenance workflows, and optimize asset behavior in real time. For the clean energy industry, this represents a profound shift: from monitoring plants to managing intelligence.

As renewable energy scales to meet global demand, ensuring maximum efficiency across every asset becomes mission critical. AI-powered performance analytics are no longer just a competitive advantage — they are fast becoming a foundational requirement for any forward-thinking operator.

For EPCs, installers, IPPs, and O&M providers in the U.S., the opportunity is clear: embrace intelligent diagnostics, empower your teams with real-time insights, and drive the next chapter of clean energy performance.

Virat Damania is Founder and CEO of Ellume Solar Inc., a complete cloud-based monitoring and Asset management platform for centralized management of power plants, with strong emphasis on data visualization, analysis, and performance reporting of your investment.

Ellume Solar Inc. | ellumeglobal.com

Author: Virat Damania

Volume: 2025 July/August

.png?r=9464)