4 Ways to Save Time on Solar Tracker Installations

Over the past decade, solar trackers have evolved to become less expensive, and easier to operate and maintain. These innovations, along with an increase in the scale of production, help explain how global tracker shipments topped 20 gigawatts in 2018- accounting for over a quarter of ground-mount installations worldwide. That's more than 87 percent of utility-scale systems in the United States.

But most trackers in the field continue to use electric motors and gearboxes. These limit design flexibility, restrict the addressable market for solar tracking systems, and increase labor costs, making it unnecessarily difficult for many projects to pencil out on sites that are not simple rectangular parcels of land.

In 2018, the market started wide adoption of motor-free, air-driven tracker systems. These systems remove design constraints; they reduce the costs of civil work, labor, material handling, and site management, all of which will help the global market reach new heights in the years ahead.

Eliminate civil work

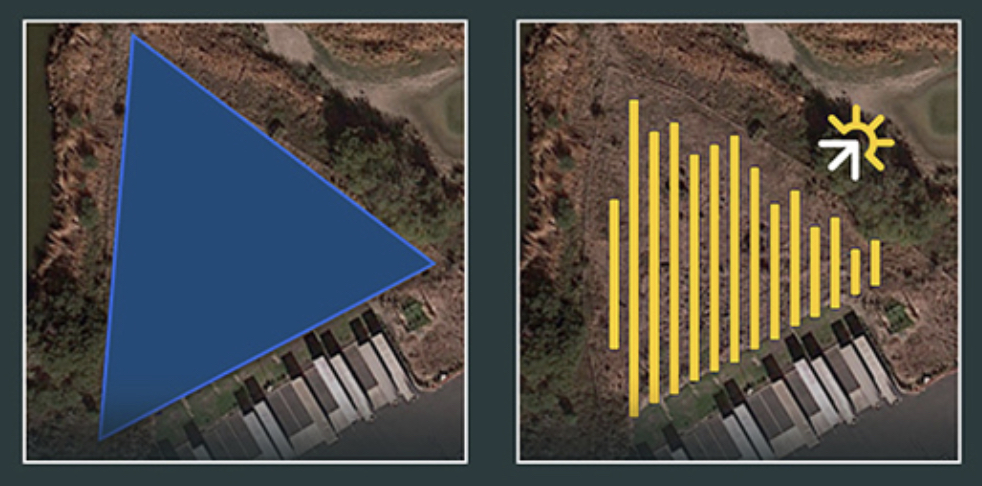

Site preparation time and expense vary from project to project. Cutting away slopes and filling in sections of land can undermine or ruin project economics. Additional unexpected costs are incurred when flood plains or wastewater runoff needs to be addressed, or if project designs need to accommodate habitats of native species. The keys to minimize these costs are to reduce or eliminate earthwork, and take full advantage of the layout flexibility available from motor-free tracking systems.

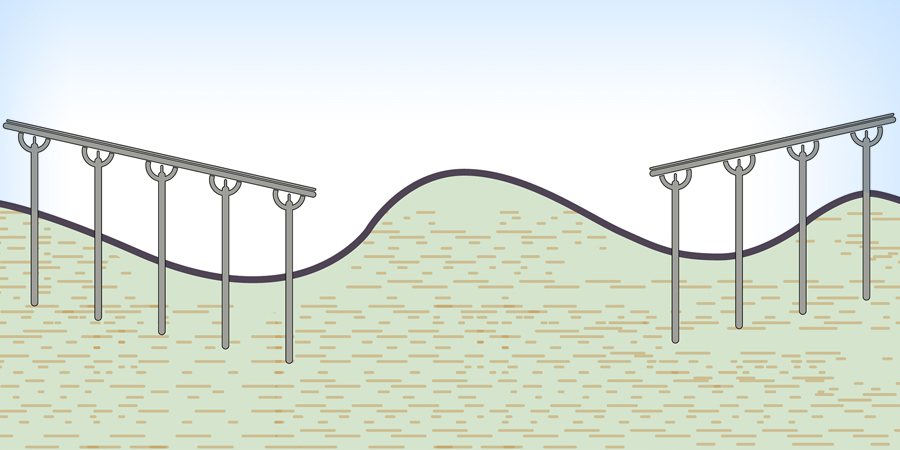

To reduce and eliminate time consuming and expensive earthwork, project developers and EPCs can use trackers with easily adjustable spans that can follow the grade, and typically eliminate the cost of civil work.

Adjustable-length spans have the added benefit of reducing post length and tracker height. A 90-module-long tracker on land with a 2 percent grade is 6 feet higher at one end than the other. This typically requires ladders to be used to complete module installation. On the other hand, a 30-module-long tracker on the same land has a height increase of only 2 feet.

Lay modules flat

Module attachment is typically the single most time-consuming step in the construction of a new project. It accounts for as much as 40 percent of time at the job site. Module installation crews spend most of their time fighting gravity - holding modules while waiting for other crew members to bolt them in place.

Two simple tracker system improvements dramatically reduce module installation time. The first eliminates torque tubes and replaces them with dual rails (purlins), so modules can lay flat across the top of the rails and crew members aren't spending time holding them in place. The second uses top mounting clamps that hold modules in place, allowing crews to finish tracking system installations without working underneath the modules.

Two simple tracker system improvements dramatically reduce module installation time. The first eliminates torque tubes and replaces them with dual rails (purlins), so modules can lay flat across the top of the rails and crew members aren't spending time holding them in place. The second uses top mounting clamps that hold modules in place, allowing crews to finish tracking system installations without working underneath the modules.

These improvements reduce direct labor time and time spent on the construction site, so that trailers, forklifts, security personnel, portable toilets, and other general conditions-related budget line items can move to the next project sooner.

Reduce walking with fewer unique components

Each unique structural component delivered to a job site increases the time wasted walking though the project. Each person walking a project, up one row and down the next, adds 1.88 miles of walking per megawatt to their day.

There are typically four types of crews, with about seven construction laborers overall. One crew distributes the components throughout the field. Another hand tightens components in place. A third tightens fasteners with a torque wrench. A fourth performs quality inspections. For every megawatt, each unique component adds 13 miles of walking.

The number of unique components in a tracking system can range from streamlined systems with three core components, to standard systems with 15 components or more. Streamlined systems can eliminate 156 miles of walking per megawatt - not including the work of removing components from pallets or collecting trash at the end of the day. Fewer unique components can eliminate a tremendous amount of wasted walking.

Use a single type of post

Use a single type of post

Traditional tracking systems use multiple types of posts (bearing posts and actuator posts) in each row. Streamlined systems eliminate this complexity, avoiding the need to distribute multiple post types to specific locations throughout the field. This reduces construction cost.

Streamlined systems also employ drives at every post. This enables the EPCs to use shorter, lighter piles, with as little as 4 feet of embedment. Smaller piles reduce post driving crew sizes, speed up driving times, and result in fewer post rejections.

Innovation in action

A motor-free, air-driven tracker system was deployed at a wastewater treatment facility in Georgia, on a terraced property with five separate grades. The facility operator had buried some old settling tanks and other equipment, capped off with a foundation and layer of soil. The challenge was to leave much of the property undisturbed. Soil grading would have been a time-consuming and expensive proposition.

The solution involved subdividing the site into five distinct arrays. Some of the arrays tapered off down to a single string of modules. Shorter piles guaranteed that ground penetrations would not compromise the foundation beneath the soil. The shorter piles also reduced the cost of steel. By running air lines to the air-driven actuators (instead of running electrical conductors, as with motor-driven trackers) there was also less trenching.

Had the installer used motor-driven trackers, each terrace would have had separate motors, with trenching and electrical wire running up and down each slope. Instead, employing a motor-free system allowed for design flexibility that translated into a more efficient and economic installation.

Matthew Schneider, chief product officer at Sunfolding, has over 15 years of product development and product strategy experience. He also co-founded RayTracker, a producer of single-axis trackers that was acquired by First Solar in 2011. As First Solar's director of global product development for PV mounting systems, Schneider ran a team that delivered over 3 GW of trackers worldwide. In addition, Schneider has worked at Microsoft and NASA. He holds degrees from St. Olaf College and Stanford University.

Sunfolding | www.sunfolding.com

Author: Matthew Schneider

Volume: 2019 May/June

.png?r=2821)