AI and the Automated Future of the Wind Industry

As wind energy production picks up speed, owners and operators are finding themselves hyper-focused on managing infrastructure efficiently. Blades are a major component driving turbine efficiency. Damaged or worn blades lead to significant efficiency loss, so regular inspections have become critical. But with inspections comes data. Massive amounts of data.

As wind energy production picks up speed, owners and operators are finding themselves hyper-focused on managing infrastructure efficiently. Blades are a major component driving turbine efficiency. Damaged or worn blades lead to significant efficiency loss, so regular inspections have become critical. But with inspections comes data. Massive amounts of data.

Whether it is a large utility provider managing a fleet of hundreds, or a private company with several turbines or farms, owners and operators are buried in data. Processing data from a single inspection can take weeks, consuming valuable time that should be spent focusing on critical areas of generating revenue.

There's a new technology in the wind industry with a unique solution to data management and analysis challenges: artificial intelligence (AI). Industry leaders have been perfecting automated, machine learning technology developed specifically for the wind industry. This revolutionary AI breakthrough is cutting data analysis time by 75 percent or more. Let that sink in.

AI is game-changing technology that creates efficiencies and expands brainpower, giving teams extra time to focus on strategy or growth.

Delegate Your Data Analysis

Sifting through hundreds - sometimes thousands - of inspection images takes human teams several days or more. Categorizing, analyzing, and transforming this data into intelligence that influences maintenance and repair decisions, takes a significant amount of time and resources; the final result may still be lacking in consistency.

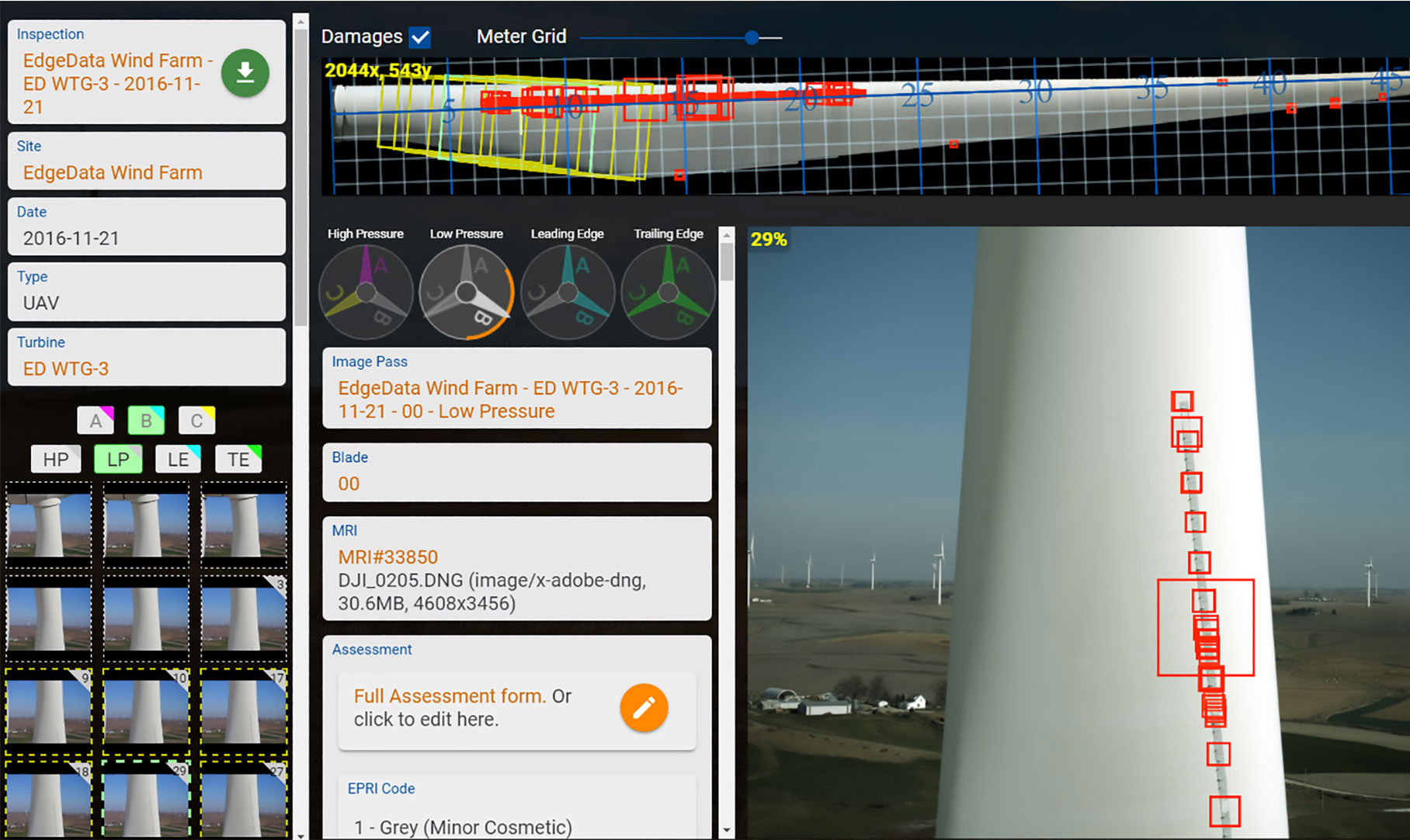

When data analysis is automated by AI, time spent in front of a computer screen is greatly reduced, freeing teams to refocus their energy on strategic priorities. This groundbreaking AI can process any type of image data, whether new data captured via drone or ground-scope, or legacy data that's backlogged and still waiting to be processed. AI is always learning - with each data set, it gets better at detecting and reporting anomalies.

Trust the Accuracy of Your Data

Regardless if you have the most talented team of analysts, human errors are unavoidable. A certain level of human fatigue exists when processing large amounts of data. Even the best can have their eyes glaze over after unending hours of analysis. It's human nature. That means the possibility of errors always exists. Can you trust that your data is accurate? Can you trust the evaluation process? Can you guarantee that your team catches the same details in every inspection? AI can.

Automated AI analysis processes provide consistency in the evaluation of damages. Each inspection builds upon the last, creating the ability to track damage and wear over time, with currently 98.8 percent confidence in the accuracy of the data. Human brains don't work this way. We're innovators and problem solvers - not data processors.

Minimize Efficiency Loss

Wind energy is dependent on maximizing efficiency. Damage, wear, and blade degradation can lead to 5-25 percent efficiency loss, which translates to significant lost revenue. Any amount of efficiency loss adds up quickly; blades can degrade at an exponential rate if left unmanaged. The key to decreasing efficiency loss is catching damage early, and planning proactive maintenance and repairs - in short, you need data, and you need it fast. You don't have days to determine if you're looking at a smudge or dirt or hairline fracture. Every minute of inefficiency and downtime comes at a cost.

Possibly the most useful benefit of AI analysis is the capacity for fast, streamlined reporting. Automated reports are generated faster than ever before, with a level of sophistication that highlights the blades or turbines that need immediate attention - and with 98.8 percent confidence in data accuracy, you can trust that what you've reviewed is correct. There's no need to comb through the entire dataset. (Unless that's your thing - we're not saying you can'tdive into the data, only that you don'thave to anymore).

Possibly the most useful benefit of AI analysis is the capacity for fast, streamlined reporting. Automated reports are generated faster than ever before, with a level of sophistication that highlights the blades or turbines that need immediate attention - and with 98.8 percent confidence in data accuracy, you can trust that what you've reviewed is correct. There's no need to comb through the entire dataset. (Unless that's your thing - we're not saying you can'tdive into the data, only that you don'thave to anymore).

The Future of the Wind Industry is Automated

AI is allowing leaders in the wind industry to take back their time. Trusting the accuracy of data grants the ability to make smart decisions, fast. Blades can now be repaired economically, before small areas of damage become big problems that severely decrease efficiency. The solution to inspection data processing challenges is here, and it's increasing our productivity, renewing our focus, and creating efficiencies greater than we ever thought possible.

Chris Shroyer is the President of BladeEdge, a cloud based, artificially intelligent analytics engine that uses inspection images, regardless of capture method, to transform raw data into actionable intelligence.

BladeEdge | bladeedge.net

Author: Chris Shroyer

Volume: 2019 March/April