PV System Math: Fewer Available Sites + Poor Planning = Money Down the Drain

A scarcity of good utility scale solar project sites, paired with insufficient engineering, can result in heavy financial losses. Ready to build sites with good soils are getting harder to come by; in order to take advantage of available farmland, brown fields, abandoned land, and waste deposits, structural and geotechnical engineers need to incorporate diligent, interdisciplinary, and hand-in-hand engineering.

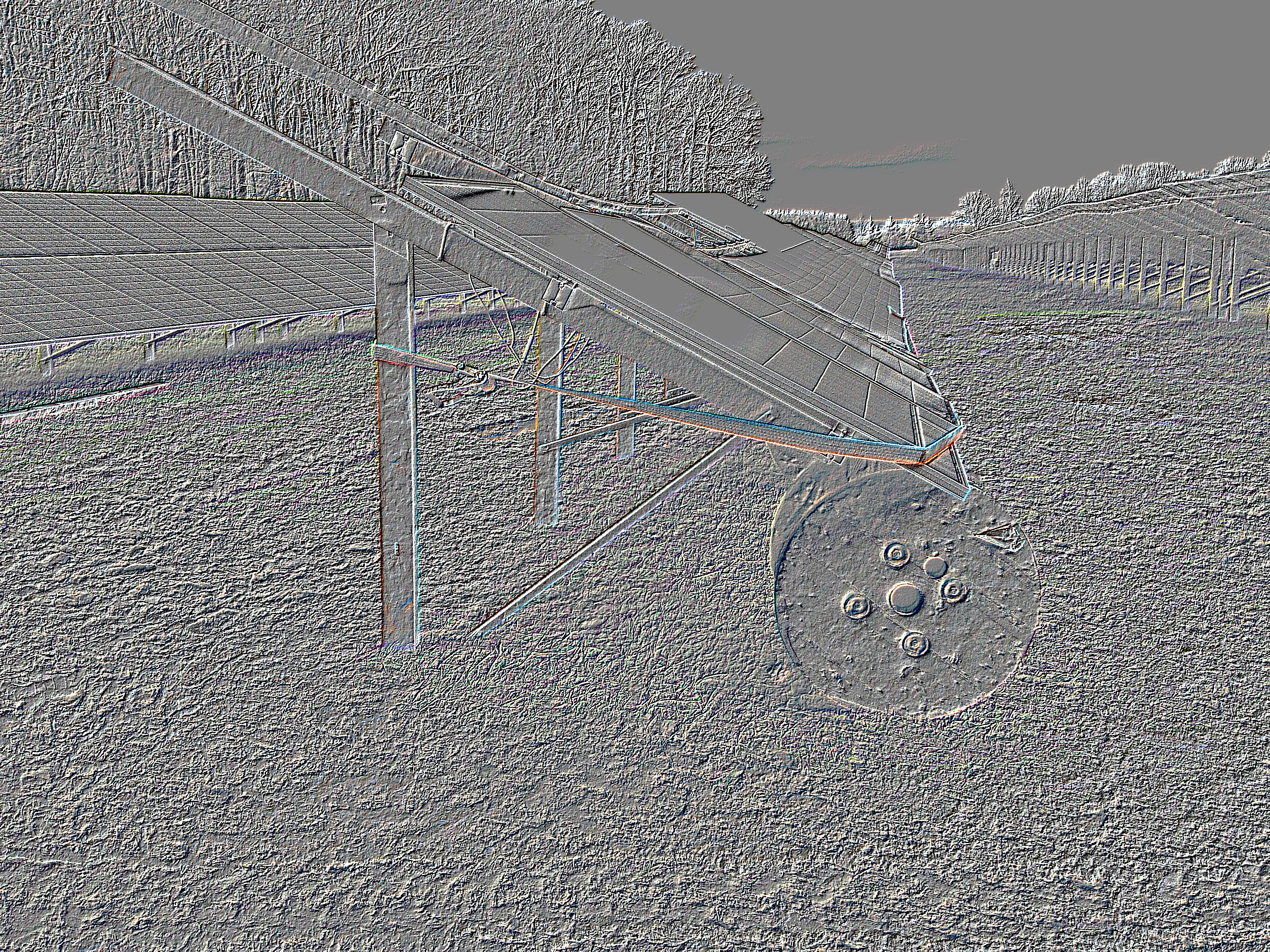

A growing number of solar systems are built on challenging terrain, with difficult and inhomogeneous soil conditions or irregular topography. At the same time, the frequency of failures and damaged utility scale solar plants is rising (see Fig. 1). Regardless of the cause of the damage, there are solutions to help overcome these challenges, thereby safeguarding investments and improving preparedness for future changes in the challenging environment.

Fig. 1- Collage of some structural and geotechnical failures and damages observed at utility scale ground mount solar farms

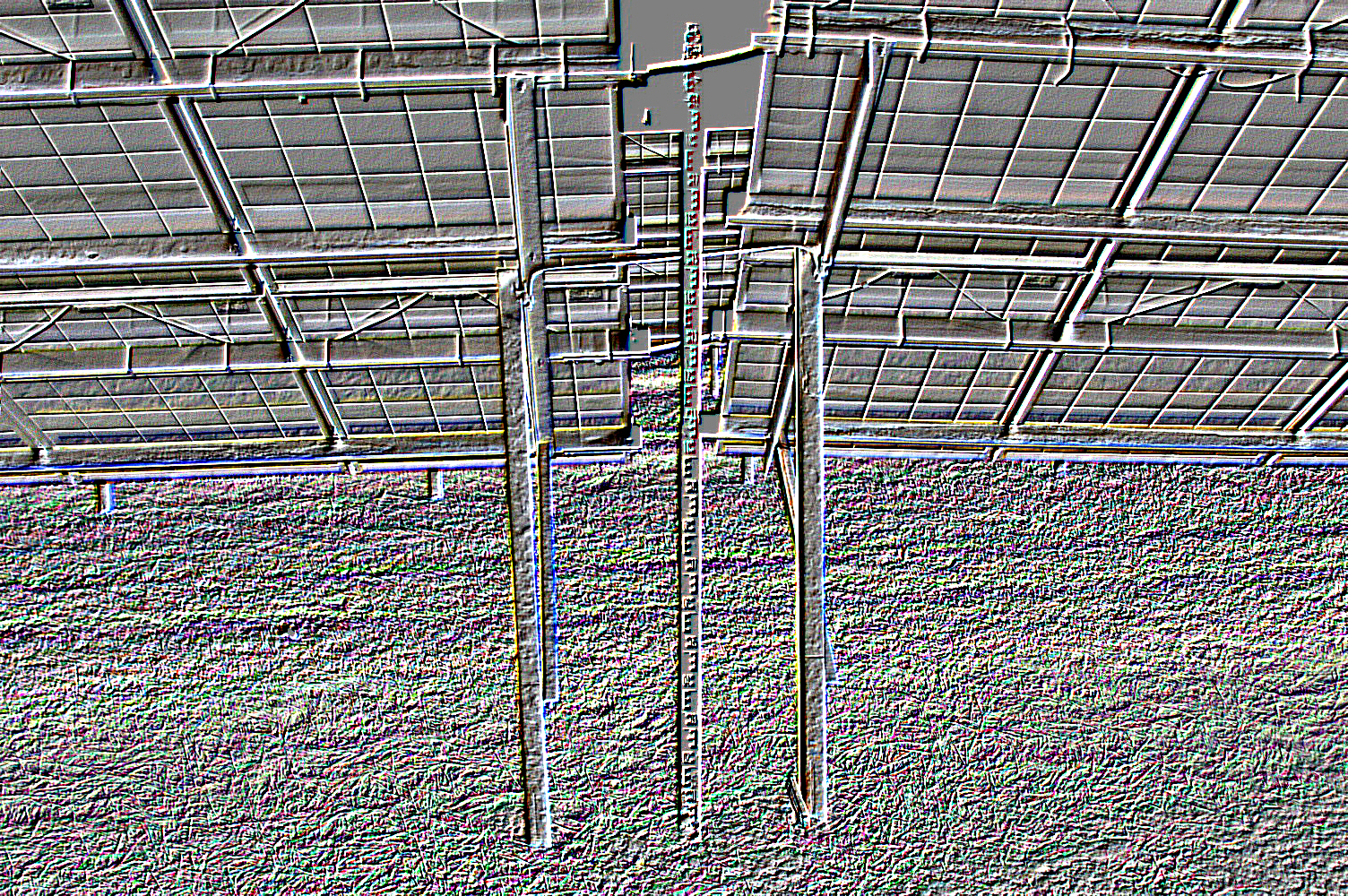

Wind load is the most frequent source of failures, followed by snow load, then dead load combined with seismic loads. Figures 2 through 10 show examples of damage to utility-scale plants due to various failures. Note that in Fig. 4, the snow load damage destroyed not only the mounting structure but also nearly all of modules of this 5MWp farm. The wooden cable drum served as a temporary support after the damage had already occurred. Also note, as observed on Fig. 9, that dynamic loads can lead to compaction of insufficiently compacted fill soils. Additionally, many contractors may attempt to conceal issued faced during installation by installing wooden wedges - not a durable construction element. This particular weakness was exposed at many foundation points during a subsequent storm.

'

'

Fig. 2- Heavy damage to structural system and foundations due to high wind load at a utility scale ground mount solar farm [Picture embossed to protect source]

Fig. 3- Significant corrosion damage observed at a utility scale ground mount solar farm

Fig. 4- Significant Snow Load Damage observed at a Utility Scale Ground Mount Solar Farm [Picture embossed to protect source]

Fig. 5- Damage presumably due to Frost Heave

Fig. 6- Example for significant differential settlement [Picture embossed to protect source]

Fig. 7- Damaged pile foot due to ramming obstructions

Fig. 8- Change of soil consistency due to climatic impacts as a potential reason for pile failure

Fig. 9- Left hand side: Dynamic loads led to compaction of insufficiently compacted Cut & Fill; right hand side: Subcontractor tried to hide problems he faced during installation

Fig. 10- Severe damage due to insufficient embedment depth of the pile foundation

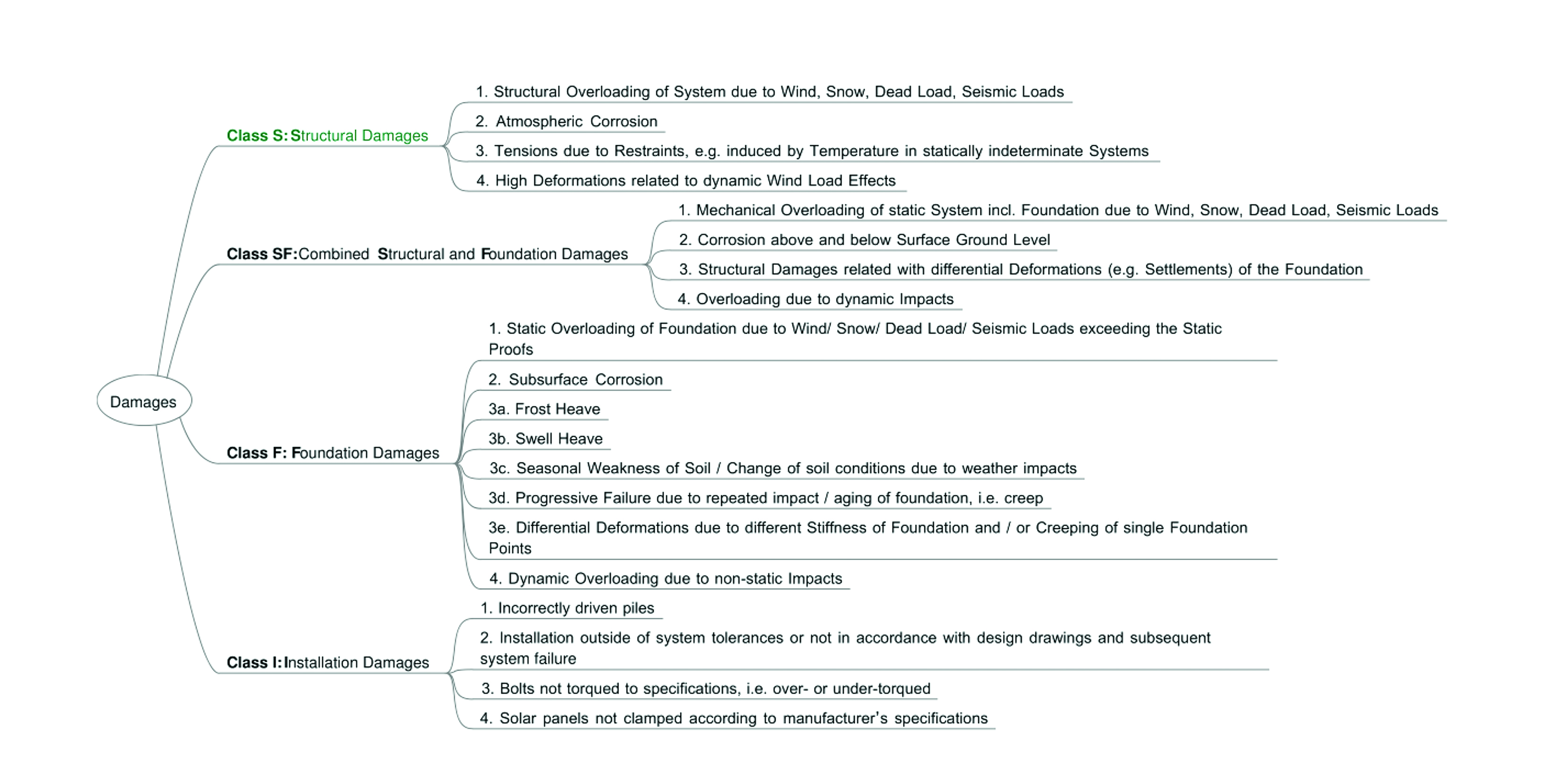

All of these images illustrate the large variety of reasons for severe damage or complete failure. In order to understand the nature of damages, and to avoid future capital loss, Fig. 11 categorizes the possible range of damages, and distinguishes between which affect the mounting superstructure, the foundation, or both. Furthermore, installation damages are categorized.

Fig. 11- Classification of structural and geotechnical damages observed at utility scale ground mount solar farms

Fig. 12- Loads acting on mounting systems of solar farms, which must be transmitted to the foundation and the soil

Fig. 13- Steel "mini pile" product examples from different manufacturers: left side: cross section of a driven pile foundation, right side: examples for ground screw solutions

The resulting loads are minimal when compared to forces acting on large building structures. However, the load effect of wind and gust activity is high compared to the dead load (weight) of a solar mounting system. Several thousand foundation elements are usually needed to build even a 10-megawatt utility scale ground mount PV system. Steel mini-piles have proven to be a very economic, quickly installable, and reliable foundation solution for small and large scale solar farms. In addition to a conventional subsurface investigation and numeric modelling, performing load tests at the site to simulate cyclic wind and snow loads, seasonal fluctuations, and soil variability at the site provides an opportunity to both confirm the sufficiency and optimize the steel mini-pile foundation design.

Therefore, system design must be conducted with professional expertise and diligent interaction between the structural engineer, and the foundation design engineer.

The task of geotechnical engineers is to design safe and economic foundations; these highly specialized civil engineers collect the measurement of the necessary soil parameters at the project site, prepare the design of the foundations, and answer all questions related to the building ground.

Jürgen Schmid is Civil Engineer, Geotechnical Engineer and CEO of AquaSoli LLC, an international engineering consultant company, which has performed pioneer work with a global experience of more than 11 GWp in geotechnical engineering of renewable energy worldwide.

Manfred Karl has been a Civil Engineer at AquaSoli since 2010. From 2006 to 2009, he worked in ARGE Richard-Strauß-Tunnel in Munich. He is based in Munich.

Jeremy Scott, P.E., is a Civil Engineer at AquaSoli, with over 17 years of diverse engineering experience across the world, in design, construction management, and environmental engineering. He is currently based in Bangalore for AquaSoli India.

AquaSoli | www.aquasoli.com

Volume: 2018 March/April

.png?r=5050)