Solar O&M - Leveraging technology to maximize ROI

In the solar industry today, return on investment (ROI) is predicated upon the ability to successfully flip ownership of a solar plant several times during its multi-decade lifespan. The initial project developer is likely to sell the asset to a long-term owner, who will frequently bundle the project into a portfolio for sale to a third party, which might sell the assets again down the road. The key to continued ROI in this economic scenario is reliable yields, both financially and energy-wise.

In the solar industry today, return on investment (ROI) is predicated upon the ability to successfully flip ownership of a solar plant several times during its multi-decade lifespan. The initial project developer is likely to sell the asset to a long-term owner, who will frequently bundle the project into a portfolio for sale to a third party, which might sell the assets again down the road. The key to continued ROI in this economic scenario is reliable yields, both financially and energy-wise.

It is incumbent upon the industry to eliminate any governor on growth, and ensure that investment in solar assets becomes increasingly attractive. Unfortunately, due to today's marketplace focus on cost-of-initial-construction, the biggest threat to profitably in buying and selling solar projects is overlooked: the actual costs of long-term operations and maintenance (O&M).

So called "forecasting" of O&M today consists of entering a standard line item as part of a bid or project budget, with no allowance for cost variances connected to the technological complexity of the mounting system, no consideration of component-by-component mean times to failure, and no regard for the differences in environmental loads and conditions. Is it logical that a centralized tracker in Southern California would have the same O&M requirements as a distributed tracker in the Northeast? Of course not. Using tracker technology as an example, a centralized tracker might employ one control unit, where a distributed tracker would require more than 50 control units for the same MWs. O&M estimates will, and should vary. What about the effect of extreme temperatures in some parts of the country on battery life? Or the effect of projects built in high-dust zones vs. those in which the modules do not need washing as frequently? These project-by-project differences are essential to accurately predicting lifetime O&M costs.

In every other industry, O&M costs are calculated based upon the sum of the mean time to failure (MTTF) of every component in a system, times its quantity. RAS (Reliability, Availability, Serviceability) is the total view. Reliability, "R", dissects every part in a system down to its individual components, and develops a mean time to failure analysis for each to determine life span and early life failure projections. Once you have "R", you can calculate a theoretical availability,"A". Serviceability, "S", is the consideration for the cost of servicing a system based upon the two other items. This discipline is measured and prevalent everywhere, except the energy industry. If solar continues to ignore the need for this sort of in-depth analysis and quantification of RAS to inform O&M protocols, it will suffer the consequences.

In every other industry, O&M costs are calculated based upon the sum of the mean time to failure (MTTF) of every component in a system, times its quantity. RAS (Reliability, Availability, Serviceability) is the total view. Reliability, "R", dissects every part in a system down to its individual components, and develops a mean time to failure analysis for each to determine life span and early life failure projections. Once you have "R", you can calculate a theoretical availability,"A". Serviceability, "S", is the consideration for the cost of servicing a system based upon the two other items. This discipline is measured and prevalent everywhere, except the energy industry. If solar continues to ignore the need for this sort of in-depth analysis and quantification of RAS to inform O&M protocols, it will suffer the consequences.

The potential risk in not embracing a new standard of nuanced, data-driven O&M, is that owners will likely be faced with project cost structures significantly less attractive than anticipated, which reduces the buyer pool.

The good news is that there is better opportunity than ever before to make O&M both predictable and more cost effective. The solution lies in the convergence of energy and technology.

Internet of Things (IoT) and Big Data are transforming businesses in every sector, and solar cannot be left behind. When it comes to energy, the solar industry can easily take advantage of these technologies to intelligently monitor, service, and maintain its solar plants, as well as mitigate and anticipate system failures so that they can be optimally serviced.

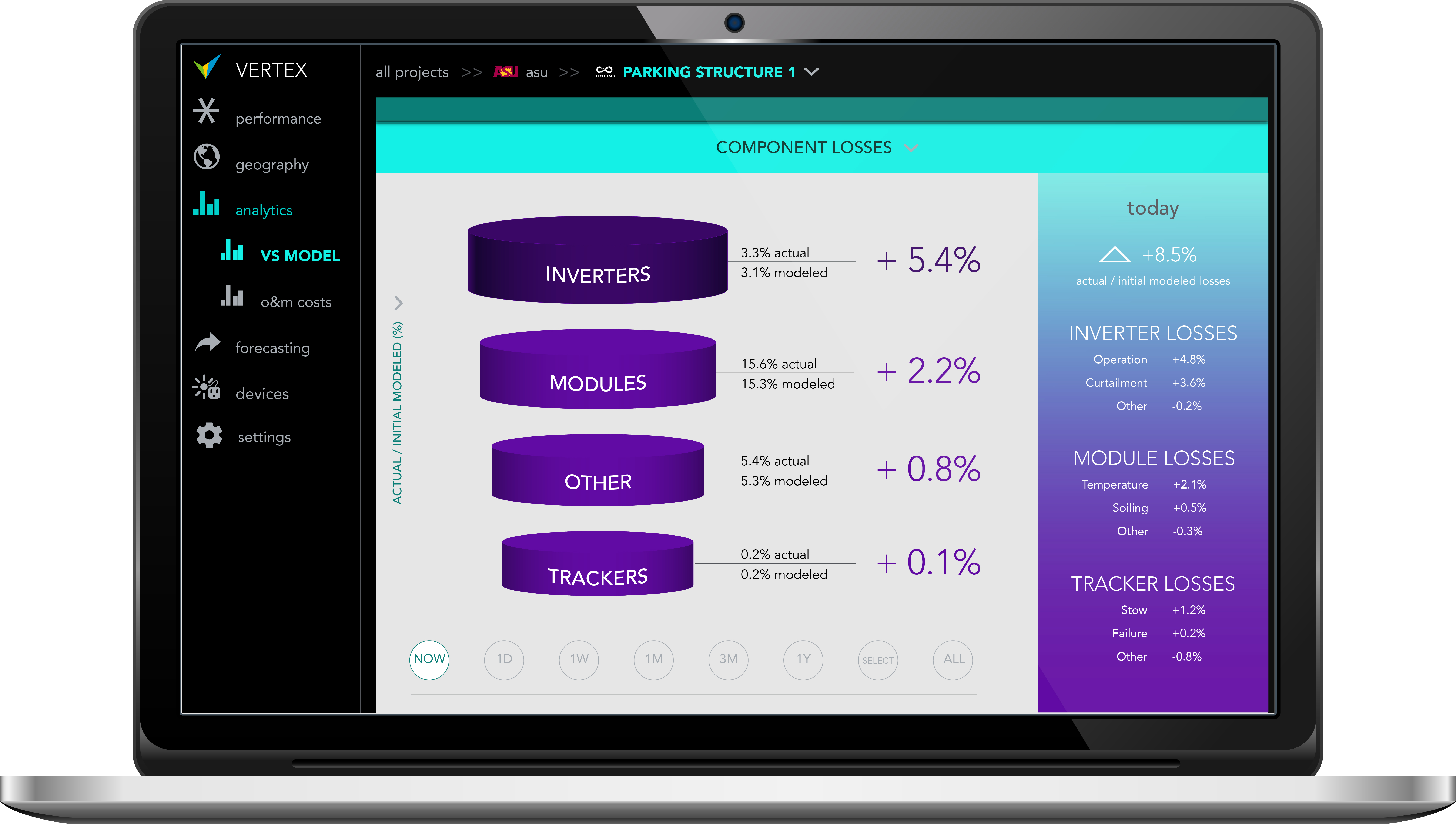

Some solar companies are using IoT technology to transform the components on solar installations into physical "networks", by embedding the systems with electronics, software, sensors, and mesh network connectivity, and then leveraging the most advanced analytics technology to translate the real-time data into actionable information. By contrast, most legacy project monitoring is done on a snapshot basis - perhaps at an interval of every 15-seconds - without maintaining an exhaustive historical dataset. Consider, as an example, a Google search. How useful would Google's search engine be if its algorithms were based on a single day of search activity, rather than all search activity from its inception? The power of the Google platform is tied to the depth of its data. Solar IoT must follow this example. By collecting and maintaining a complete history of real-time data associated with a given system, Solar IoT will enable meaningful analytics to guide long-term asset valuations and investment.

Each subsequent solar project will provide a richer data set upon which to base O&M projections. This data will also make it easier to sell solar assets by producing detailed, historic performance records. Not unlike the increased value of a car that comes with a complete maintenance record, solar projects that include long-term, component-by-component performance data will be more bankable.

Each subsequent solar project will provide a richer data set upon which to base O&M projections. This data will also make it easier to sell solar assets by producing detailed, historic performance records. Not unlike the increased value of a car that comes with a complete maintenance record, solar projects that include long-term, component-by-component performance data will be more bankable.

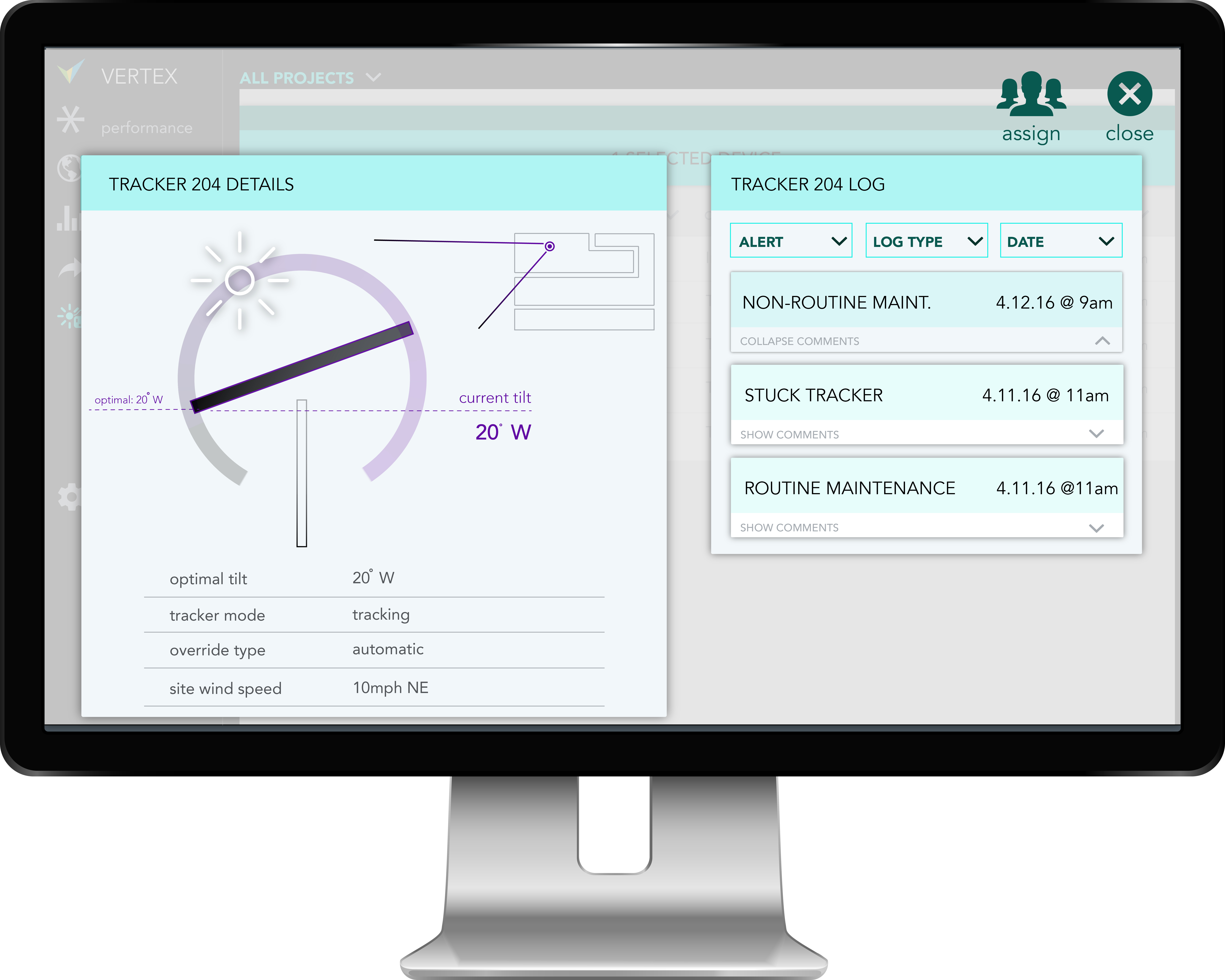

Beyond O&M projections, collecting more data and making it actionable also makes O&M more efficient, and reduces costs. The ability to dynamically and remotely troubleshoot without rolling a truck, is important to the financial success of a project. Similarly, targeted alerts that pinpoint the source of a problem, down to the individual component level and location, will dramatically streamline corrective O&M actions.

The insurance industry knows how long a person will live, and the automotive industry knows how long its cars will last, because they are constantly collecting data and updating their models. It is time for solar to do the same. There is no excuse for not leveraging technology to gain a thorough understanding of how every project component will perform over 20 years or more. This knowledge must guide and help revolutionize how we optimally maintain our assets and make investment decisions.

Michael Maulick is CEO of Sunlink Corporation.

Michael Maulick is CEO of Sunlink Corporation.

Sunlink Corporation | www.sunlink.com

Volume: 2016 November/December

.png?r=2431)