Lidar

The key to improving wind farm wind drought tolerance

2015 saw below average winds across much of the United States, with wind energy production down six percent, despite a nine percent increase in capacity. Worse still, this trend is persisting into 2016.

2015 saw below average winds across much of the United States, with wind energy production down six percent, despite a nine percent increase in capacity. Worse still, this trend is persisting into 2016.

Fortunately, developments in remote sensing technology now allow for deeper, more detailed wind characterization at operational and pre-construction wind farms. Site-specific trends can be identified and corrective improvements introduced, mitigating the impact of so-called wind droughts, and improving yearly economic returns.

These improvements are made possible by the additional capabilities that lidar, a radar-like technology that uses laser light to measure the speed and direction of the wind, offers over historical industry methods.

A typical three-anemometer meteorological (met) mast provides wind speed data for three heights at one map coordinate. The wind energy industry has become proficient at extrapolating wind speeds vertically up to wind turbines’ hub height, and laterally out to turbines’ specific coordinates, but this extrapolated data can only ever be an approximation.

In contrast, directional lidar creates a dense mesh, offering precision spatial or temporal insight about wind micro regimes immediately surrounding a turbine. (Spatial/temporal trade-offs can be managed by budgeting time for both methods during lidar campaigns).

To use a medical analogy, if a met mast was an x-ray, lidar would be a PET scan, providing highly detailed information about narrowly targeted regions, leading to a more precise diagnosis and a more accurately prescribed solution.

As the same recurring factors tend to impair performance in onshore wind farms, it is important to integrate domain knowledge with data analytical techniques in order for the right solutions and improvements to be made.

Turbine factors

Turbine factors

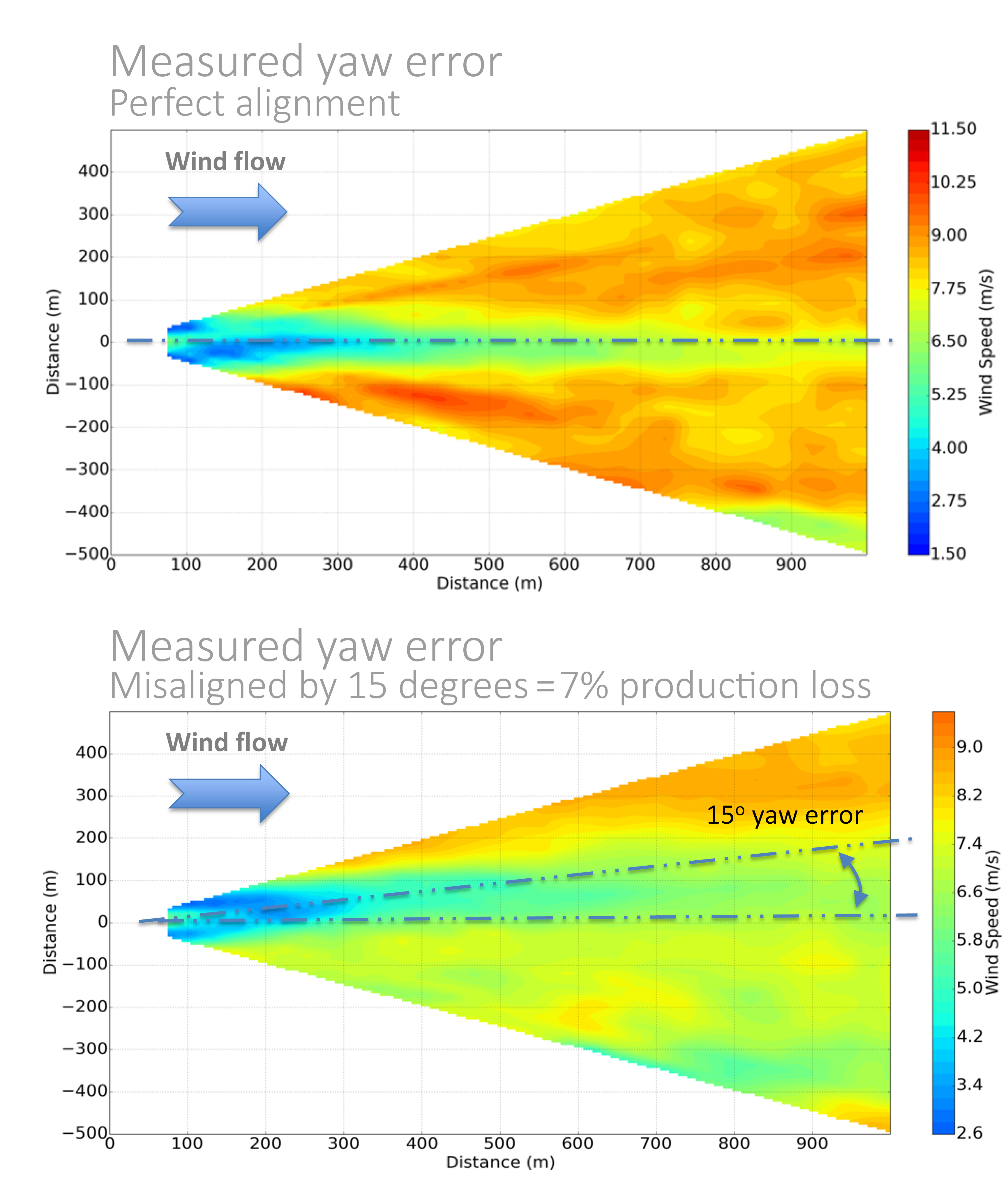

Dynamic yaw errors can result when a wind turbine does not accurately rotate to align with incoming winds. Difficult to measure with nacelle-mounted wind vanes, these errors can be measured directly using lidar, allowing for control systems adjustments to be made, to keep the turbine properly realigned. This provides the dual benefit of increased energy production, up to 3 percent, along with reduced cyclic loadings on key components such as blades and gearboxes.

Particularly for older turbines, historical compromises in blade design, often for the sake of manufacturability, can lead to aerodynamic stall, reducing a turbine’s annual energy production. Aerodynamic enhancements such as vortex generators can be deployed, but performance validation is key to ensure they are having the intended effect. Lidar measurement of air flow around the turbine establishes the optimum positioning of the devices, and then confirms the enhancements are working as intended. Yaw error can significantly impair WTG production; in the example at left, a 15° yaw error resulted in a 7% loss in WTG production.

Terrain factors

Lidar data can be paired with computational fluid dynamics (CFD) software to accurately assess the effect of terrain and nearby forestry on wind energy yields, and devise optimum forestry restructuring plans in conjunction with local stakeholders. In highly-forested areas, improvements can be substantial, with owners increasing annual energy production by over 5 percent. As tree cover also increases air turbulence, restructuring can also reduce ongoing maintenance requirements and consequently, costs.

Moving forward

Moving forward

Just as the map is not the territory, the software model is not the wind farm. It is subject to real world complexities ranging from microclimates to construction error and equipment limitations, among others.

Although it has historically been difficult to compensate for these factors, lidar technology has increased the ability to diagnose the exact causes of wind farm underperformance. Specific corrective measures can then be prescribed to improve yield on both onshore and offshore wind farms based on real, comprehensive, accurate data. A combination of solutions could realistically provide yield improvements of between 5 and 12 percent.

By utilizing the insight afforded by remote sensing, and the application of measures to improve wind farm performance, in low-wind years, project economics should be able to tackle future wind droughts head on, and have better tolerance to the economic impacts of a low wind year.

While the benefits of site-optimized wind farms accrue annually in the form of higher energy yields, they will be most apparent during years of lower-than-expected winds, with the higher production baseline helping to offset the impacts of wind droughts. While a wind farm’s economics will never be drought-proof, lidar offers a path for their becoming drought-resistant – a message SgurrEnergy believes will resonate with owners, operators, lenders, and vendors in coming years, as the American wind industry approaches its milestone 100th GW of installed capacity.

Matthew Klippenstein is the renewable energy consultant for SgurrEnergy

SgurrEnergy | www.sgurrenergy.com

Volume: 2016 May/June