Maximizing the Wind: With isothermal compressed air energy storage

If you ask the average person about energy storage, they’ll probably talk about batteries. But, ask a utility executive, grid operator, or wind farm developer and the answers will vary as much as the wind itself.

Wind energy installations are increasing around the world, adding degrees of supply variability and challenging grid stability. Grid operators are taking a close look at the impact of increasing penetration of highly variable wind energy, and how energy storage can play a role in stabilizing the electricity network. In many regions, the issue is not if grid-stabilizing solutions will be needed, but when.

Although today’s level of wind penetration in North America is not yet at a point that creates significant grid instability, utilities and grid operators are certainly paying attention. Based on the growing confluence of industry studies, utility initiatives, regulatory orders and filings, and early results from initial projects, the market clearly recognizes that expanding wind power resources will require stabilizing support.

One of the key sources of support can be deployment of grid-scale energy storage systems, and technology developers are racing to provide them.

Weighing storage options

So, what might an ideal storage solution look like? To deliver the greatest benefit, it must be reliable, cost-effective, and unconstrained by geography. In high-energy applications, such as wind integration (i.e. four to six hours, or more), bulk storage must have a long cyclic life, low initial and O&M costs, and be able to perform many deep-charge/discharge cycles without degradation.

An obvious question is: why not use giant batteries? Despite advances in chemistry and improvements in cost, new battery-based solutions have largely been limited to short-duration, high-power applications. They can provide short bursts of power to smooth out variations in frequency, power, and voltage. However, batteries cannot provide extended duration, long-life, utility-scale performance. To do so requires storing and discharging energy at high rates (hundreds of MW), in very large amounts (thousands of MWh), over many thousands of cycles, for a utility-standard period of 20 to 30 years. The limited, deep-discharge cycle lives of batteries (a few thousand cycles at most) make them impractical for such long-term, high-energy applications.

Recent grid-level battery installations have, therefore, focused on high-power applications, such as frequency and voltage regulation. For example, Duke Power’s recently commissioned Notrees Windpower Project in Texas is a 36-MW/24-MWh system (at an estimated cost of $44 million), which is slated to provide several services, including smoothing and frequency regulation. A technical and economic assessment by the Electric Power Research Institute (EPRI) and Sandia National Labs, expected at some point in the future, will evaluate its performance in these functions.

There are non-wind, bulk storage applications, but these also tend to be of high power and short duration. AES Energy Storage has two battery storage projects now operating at AES-owned power plants in Northern Chile. One is a 12-MW system that uses Li-on batteries from A123 Systems to provide short-term spinning reserve. The second is a 20-MW battery plant that operates in tandem with a 544-MW coal plant to provide up to 15 minutes of spinning reserve. That system comprises about one million Li-on battery cells, divided among ten, 2-MW battery containers and five, 4-MW power control containers.

Finding grid-scale solutions

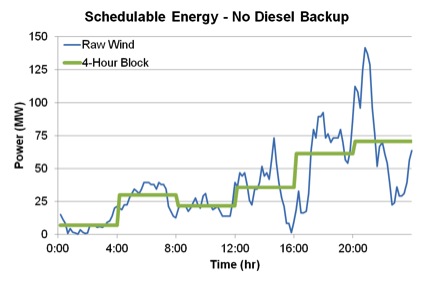

This graph depicts a typical 24-hour period of wind farm output (blue line). The energy levels reflect significant generation peaks and valleys—with a >125 MW swing over a four-hour period. The addition of ICAES in a potential application (green line) adds certainty to grid operation by firming variable wind energy and transforming it into a predictable, schedulable product. ICAES is able to provide fast-ramping reserve energy, while zero-minimum generation allows more wind to reach load, minimizing the need for fossil fuel-fired balancing power.

For long-duration/high-energy applications, pumped hydro and conventional compressed air energy storage (CAES) have proven to be the most effective methods of bulk storage from a cost and performance standpoint. However, conventional CAES, which relies on underground salt caverns for air storage, and a natural gas-fueled combustion turbine to generate power as the compressed air is expanded, is used in only two places worldwide. The last system was built in 1992, and several recent proposed projects have been cancelled due to escalating costs and other issues.

Pumped hydro is by far the most widely used bulk energy storage method today. It represents more than 99% of bulk storage capacity worldwide (around 127 GW, according to EPRI), but has limited potential for expanded use. The types of sites needed for new pumped hydro systems are few and far between, and environmental concerns often cause delay or cancellation of projects. As a result, a few companies are devising new methods to move water around. Ultimately, conventional CAES and pumped hydro are limited by scale, siting, and/or emissions, requiring enormous capital outlay—and patience.

Building on the advantages of CAES (economics, efficiency, scalability, and mechanical durability), with the added benefits of flexible siting and clean, fuel-free operation, is the more advanced isothermal compressed air energy storage. Isothermal CAES captures the heat produced during compression by trapping it in water, and storing the warmed air-water mixture in conventional pipelines or fabricated in-ground storage vessels. When energy is needed, the process reverses and the air expands, providing greater efficiency because of the presence of heated water in the system. No fuel is needed to re-heat the air, and no emissions are produced.

Calculating carbon footprints

When looking at long-term grid solutions, another important factor to consider is the carbon footprint of various storage methods. One way to measure this is the return on energy expended to build a system. Until recently, these energetic costs had never been researched or quantified. A study published in March by Stanford University’s Global Climate and Energy Project (GCEP) looked at the “energy stored on investment,” or ESOI, of various technologies, including five types of batteries (namely, lead-acid, lithium-ion, sodium-sulfur, vanadium-redox, and zinc-bromine), as well as pumped hydro and CAES.

The study found that all five batteries have exponentially greater embodied energy costs when compared to the two pre-dominant bulk storage methods. In other words, thanks to their much longer lifetimes and relatively basic components (earth, air, water, steel), pumped hydro and CAES can return 20 to 25 times as much energy over their operational life, compared to the top-performing batteries. The study didn’t look at emerging bulk storage technologies, such as Isothermal CAES, but these systems are also made up of proven industrial components (including air, water and steel), so the future looks promising.

The final word

Real-world experience has shown that energy storage can be highly useful in integrating wind and solar power, as well as providing ancillary services to the grid. Isothermal compressed air energy storage overcomes the limitations of conventional CAES, combining the low-cost, large-scale, and long-lifetime benefits of mechanical storage in a site, with zero-emissions. With such advantages, isothermal CAES can provide the flexibility to expand wind penetration in challenged grids.

Richard Brody is the VP of Business Development for SustainX and has over 20 years of experience in technology-based business development.

Later this year, SustainX will connect and begin operation of its first megawatt-scale ICAES system—a 1.5-MW pilot at its facility in Seabrook, New Hampshire.

SustainX

www.sustainx.com

Author: Richard Brody, Ph.D

Volume: May/June 2013