Improving the Economic Viability of Renewable Resources: Using high-capacity conductors

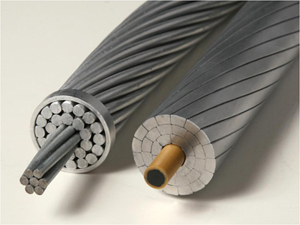

ACCC high-performance conductors use a high-strength, lightweight carbon and glass fiber composite core that is substantially stronger than its steel counterpart. The added strength allows longer spans between fewer and/or shorter structures, which can reduce upfront capital costs and minimize environmental impacts. The composite core’s lighter weight allows the incorporation of additional conductive aluminum, using compact trapezoidal strands, without any overall weight penalty. The increased aluminum content decreases conductor resistance, which can reduce line losses by 30% to 40%. The composite core’s very low coefficient of thermal expansion also prevents conductor sag when operated at higher temperatures under peak load conditions. This serves to improve grid reliability by maintaining safe ground clearances.

Preserving grid lines

Although new feeder lines typically deliver power from renewable resources directly to the grid, often times the existing grid lines are not capable of carrying additional current due to thermal sag. As transmission lines carry more current, their electrical resistance causes the lines to heat up. This heat causes linear expansion of the conventional steel core, which increases line sag. Excessive line sag can cause dangerous arching or flashovers to adjacent or under-built wires, vegetation, or other structures. It can also cause outages.

A high-performance conductor of the same diameter and weight can be used to replace existing conventional ACSR conductors to increase line capacity and reduce line losses without increasing line sag.

One example of a successful replacement included the replacement of 10.5 circuit miles of ACSR Dove-sized conductors of a transmission line in Spain, with an ACCC equivalent. The plan included the addition of 80 new turbines for a total of 160. Using ACCC conductors allowed this transmission project to double the capacity of its existing 66 kV line, without having to replace, lengthen, or reinforce any existing structures. With an anticipated load factor of 35%, the estimated savings from line loss reductions alone were $26,507,000 over the first 10 years. The ability to re-use existing lattice structures also saved millions of dollars on upfront capital costs, as well as several months of construction time and potential revenue loss.

Higher power

In addition to reducing capital costs, a high-performance ACCC conductor’s reduced line losses can enable the delivery of more energy from a given asset. This can amount to tens of millions of dollars in increased revenue over a project’s anticipated service life. Conversely, a reduction in line losses can also improve upfront capital costs by delivering the same amount of power with less upfront generation investment.

Unlike a typical base-load coal or nuclear plants, where a specific output can generally be recognized, renewable projects often have much greater operating windows, where the electrical current generated can vary widely. Under these wide and often transient conditions, conventional ACSR conductors have substantial limitations that relate to ultimate load carrying capability, thermal sag, and exponentially increasing line losses.

An ACCC conductor is ideal for renewable applications due to its high-capacity and low-sag characteristics. Its high-strength, dimensional stability, and added aluminum content also make it well suited for upgrading existing transmission lines to deliver up to twice the power of conventional ACSR conductors of the same diameter and weight. This offers utilities a cost-effective means of upgrading existing transmission lines without having to make expensive and time-consuming structural upgrades to accommodate new sources of renewable energy.

ACCC conductors were first introduced in 2005 and, since that time, additional testing has subsequently led to the successful deployment of approximately 10,000 miles of conductor at over 220 project sites worldwide.

CTC Global

www.ctcglobal.com

Author: Carl Ulrich

Volume: September/October 2012

.jpg?r=2094)