Solving the Wood Waste Dilemma: Briquetting solutions for wood processors

For as long as there have been sawmills and wood processing facilities, operators have struggled with the issue of what to do with all of the sawdust and wood residues created during production runs. Years ago, before much attention was paid to the negative effect that wood waste disposition might have on the natural environment, solutions included dumping collected sawdust into nearby streams and rivers, or allowing the waste to accumulate over time before burning it on site. Fortunately, today’s wood processing industry is much more mindful of environmental sustainability, and is working to develop cleaner ways to dispose of its waste products.

For as long as there have been sawmills and wood processing facilities, operators have struggled with the issue of what to do with all of the sawdust and wood residues created during production runs. Years ago, before much attention was paid to the negative effect that wood waste disposition might have on the natural environment, solutions included dumping collected sawdust into nearby streams and rivers, or allowing the waste to accumulate over time before burning it on site. Fortunately, today’s wood processing industry is much more mindful of environmental sustainability, and is working to develop cleaner ways to dispose of its waste products.

Wood processing mills throughout Europe, and increasingly now in North America, are embracing briquetting as viable alternative for wood waste disposition. Briquetting is a cost-effective, efficient process that produces blocks of compressed sawdust and wood residues that make the waste cleaner and easier to manage at the facility level. Briquetting can even provide additional revenue streams, acting as a carbon-neutral source of heating fuel.

Better climate, better business

In the real world, companies that want to do what’s right for the environment have to do it in ways that are also good for business. Some well-known methods of wood waste disposal popular in today’s North American wood processing industry include repurposing the residuals as animal bedding and pelletizing, which involves compressing the waste into tiny pellets for use in pellet stoves. Although these methods are more eco-friendly than sending the waste to landfills or burning it in incinerators, they aren’t necessarily the most cost-effective or efficient ways of enacting environmental responsibility. For starters, both of these disposition approaches require substantial investments of time and energy, and they present storage and logistics challenges that, in light of a return on investment (ROI), can further drag down feasibility.

On the surface, reusing wood waste as animal bedding seems like a straightforward way to dispose of it, and it is, but there are other factors that make it less attractive. First, storage of tons of sawdust and residues is a headache that most facilities could do without. The waste is cumbersome to transport and, because wood dust can be highly combustible in large concentrations, it can pose serious safety risks. Many processors end up simply giving the waste away to farmers or animal bedding producers just to get rid of it (granted, in some situations it can sell for up to $40 per ton). Unless done well, however, the proposition doesn’t make much business sense.

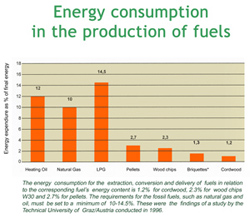

Pelletizing has the potential to generate greater revenue, and it’s largely easier on the bottom line, but it still has drawbacks. Concentrating wood residue into tiny pellets requires a tremendous amount of energy. Not only does this drive up utility costs and eat into profitability, it also undermines the environmental benefits as it consumes additional energy that’s harder to offset. The process is also labor and maintenance intensive, requiring diligent oversight and frequent wear-part replacements. Although somewhat easier to manage logistically than the loosely packed wood waste intended for animal bedding, pellets are challenging because they tend to roll around and must be boxed or bagged. Moreover, the pellet market is limited because pellets can only be used in specially designed devices like pellet stoves. This means that any revenues generated by the pellets are dependent on the success of one particular industry.

Briquetting solutions

Briquetting solves all of these problems. Briquetting is a popular disposition method in Europe, and has been for many years, mainly because there’s a robust market on the continent for briquettes as a source of eco-friendly heating fuel. The method is now coming into its own in North America as more businesses become aware of it, and the market for briquette-based fuel continues to grow.

More flexible than pellet fuel, briquettes can be used in any fire-burning device and typically sell to distributors for between $140 and $200 a ton. Not a bad return for wood waste that might otherwise have been given away.

Briquetting systems are good for the environment and good for business with an excellent ROI—and the source of added revenues via the production of carbon-neutral heating fuel. From the processing floor to the warehouse, briquetting improves operations by eliminating dirty and potentially dangerous wood dust from the air, where it could damage machinery or threaten the health of employees and visitors.

These systems are easy to install and operate, and require less than half the energy of pelletizing machines to dispose of wood waste. In some instances, briquetting machines have been installed and integrated into milling operations in as little as one day. And, as briquettes are typically square in shape as opposed to round or cylindrical like pellets, they can easily be placed on palettes and shrink-wrapped to simplify transportation and warehousing—saving time, money, and valuable floor space.

As briquetting becomes more common throughout North America and beyond, its benefits to businesses and the environment will continue to grow.

RUF

www.ruf-briquetter.com

Author: Greg Tucholski

Volume: November/December 2011