Don't Dig There - Cutting down on line strikes (and related accidents) in renewable energy development and construction

The world needs renewable energy now more than ever. Fortunately, renewables are here to stay, but ironically, in the pursuit of clean energy, developers run the risk of damaging existing underground power infrastructure. The risk is real, and the potential for damage - to people, capital, and the environment - is serious.

.jpg)

(photo credit conor_the_digger_driver)

Wind towers are being erected, collection lines are being trenched, and solar panel mounts are being driven into the ground. In the world's attempt for advancement and expansion of renewable energy, hundreds of thousands of acres of land will become disturbed. In the past year, 18 percent of all electricity generated in the United States was linked to renewable energy sources. Within the next ten to fifteen years, companies will begin breaking ground to create even more opportunities for the renewable energy sector, including solar panel manufacturing, wind turbine fields, additional water-generated power plants, and even electric vehicle (EV) charging stations. However, in order to start that journey, subsurface contractors will need to scan and make sure each location is safe to begin building. This is no small task: in 2019 alone, there were 532,000-line strikes, with a utility strike happening every 62 seconds. The last two decades saw these accidents directly (and indirectly) result in over 30 billion dollars-worth of damage, 2,400 injuries and over 400 deaths, Fortunately, despite the bleak outlook of these staggering statistics, there's an answer to the question, "How do we mitigate these risks?" And that answer is called the "SIM Method."

First and foremost, Subsurface Investigation Methodology, or SIM, is a process all successful subsurface inspection companies must follow in order to create a safe and secure job site. The SIM method entails a set of steps to prevent accidental and unwanted damages when drilling or digging underground. Companies that utilize the SIM method help prevent these costly expenses by scanning concrete, locating underground utilities, and video inspecting subsurface pipes. How does that relate to renewable energy innovations?

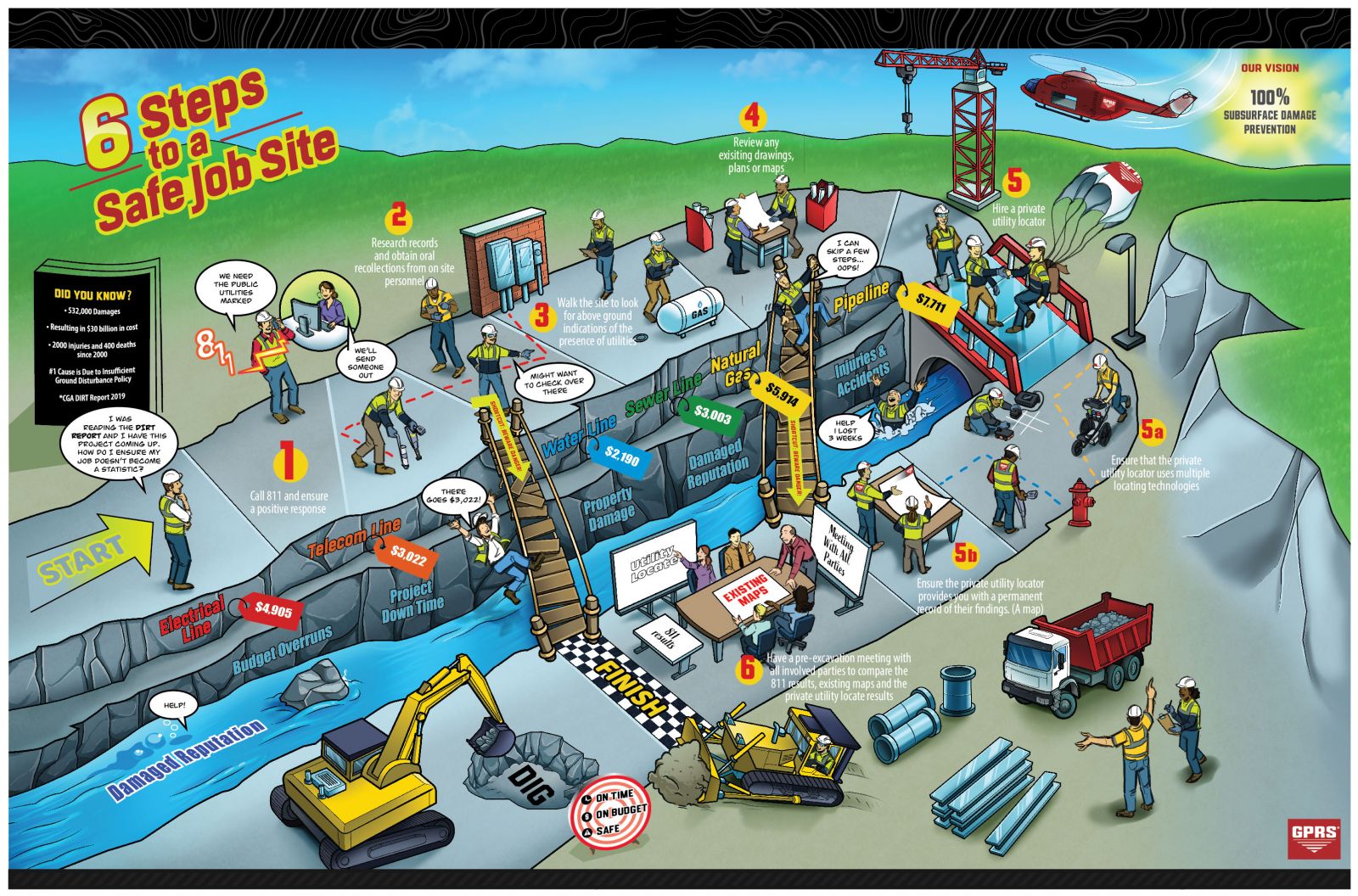

Let's say you own your own subsurface/utility locating business. You get hired by a company in the Renewable Energy Sector for an expansion involving solar energy, wind energy, or EV Charging Stations. In solar, for example, chances are you'd be installing a photovoltaic power station, applying a canopy-mounted solar panel to distribution/transmission lines, or simply building a rooftop solar panel source for a residential home or commercial business. Before you can begin excavating, you must perform utility locating and mapping services to get a better understanding of the underground set-up. "Can't I just call the 811-number, saving time and energy, instead of hiring a subsurface contractor?" That's a good start; calling 811 should always be the first step in the process, but there are quite a few more stages you'll need to follow to ensure a safe job site. You must research records, walk the site to find any above-ground indications of utilities, and review any existing drawing or maps.

Every industry has set standards they must follow to ensure success. Renewables adhere to the same processes. Whether a wind farm, EV charging stations, or hydropower - each project requires careful, detailed excavation to ensure that the surrounding area, crew members, and local residents are protected from potential harm. If you begin to take shortcuts, trying to cut corners on a project, you run the chance that you'll become a part of the wrong side of statistics, resulting in another billion dollars-worth of damages, or worse, another neglectful death.

Damages add up when you cut corners

Damages add up when you cut corners

Applying a filter (SIM) to a potential subsurface contracting job prevents companies from accidents like line strikes. Notfollowing the SIM process prevents lower end companies from safely scoping out a job site, which has been proven time and again to result in costly, unforeseen damages, and even death.

Subsurface inspectors are in the business of helping in a safe bubble of protection, something the rapidly expanding Renewable Energy Sector needs in spades. If you want to provide a seamless experience for construction crews, while growing your profits, then you'll utilize a SIM qualified subsurface company before breaking ground; much like a secret network of tunnels, our connection and utility lines run rampant underneath the cities and towns of our country, providing power to the homes and businesses of millions of Americans worldwide.

With the combined vision to provide safe, clean energy to everyone across the US, it's vital to provide an accurate set of information regarding underground facilities and pipelines during the construction process. Given the costly damages, both financial and physical, that come with cutting corners on an important project, would you be willing to take the chance on things going wrong?

Protection is what matters the most when venturing into unknown waters. Subsurface inspectors and utility locators provide the security that allows booming industries to branch out, grow, and succeed.

Corey Brecht is Market Segment Renewable Energy Leader at GPRS, which specializes in utility locating. At its dedicated safety training center, GPRS requires every project manager to complete an extensive training program before they can perform field services on a job site.

GPRS | www.gp-radar.com

Author: Corey Brecht

Volume: 2021 March/April