Misapplied Derating: How wind farm owners lose hundreds of MWh each year

Turbines have been operated at a fraction of their maximal efficiency for years - but this isn't necessarily a bad thing. Limiting a turbine's performance is known as derating, and it can benefit both turbine lifetime, limit noise, and support the successful integration of wind assets into the grid.

Turbines have been operated at a fraction of their maximal efficiency for years - but this isn't necessarily a bad thing. Limiting a turbine's performance is known as derating, and it can benefit both turbine lifetime, limit noise, and support the successful integration of wind assets into the grid.

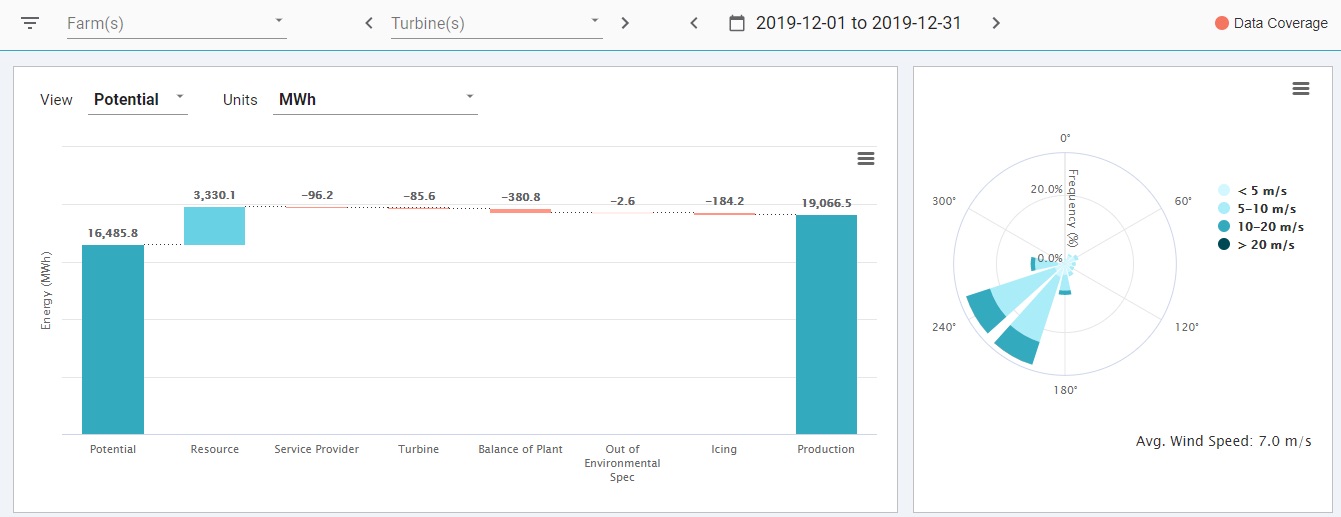

While it is accepted that derating turbines comes hand in hand with a reduction in energy generation, derating strategies can often be misapplied, leading to wind farms unnecessarily losing hundreds of MWh each year - leaving tens of thousands of dollars in revenue on the table.

Derating can sometimes occur without the asset owners' knowledge; as the resulting decrease in performance is usually under 5 percent, derating is easily lost in the noise of other causes of underperformance (such as windspeed, yaw misalignment, or mechanical wear-and-tear). Advanced digital tools can identify the patterns of underperformance that indicate the turbine has been unnecessarily derated - and why.

By comparing the times that derating is occurring to other data streams (such as windspeed and air density), it is possible to establish whether derating is necessary, and ensure any subsequent loss in revenue is limited. Artificial intelligence (AI) can drive in-depth data analysis, stopping unnecessary derating, and revenue, from slipping under the radar of wind farm owners.

Turbine data can also be used to analyze why these derates have been misapplied, allowing owners to prevent further lost revenue. Below are three of the most common causes of unnecessary derating that owners must tackle to get the most out of their fleet.

Sensor calibration

Derating can be applied in response to environmental conditions. For example, storm conditions can cause significant damage to active turbines, presenting a major safety risk for the surrounding area. Therefore, derating can be a way to apply the brakes to the rotor in extreme weather.

However, if the turbine "senses" adverse weather conditions when there are none, derating conditions will be switched on unnecessarily. When sensors have not been properly calibrated, control systems might begin derating turbines based on faulty sensor readings that indicate adverse conditions, even in the midst of benign weather.

With any control system, it's important to make sure that sensors are properly calibrated for the environment. Sensor error can be identified if the turbine data does not match with other data streams for environmental data. While this is an arduous process with traditional data analysis methods, AI can find these errors quickly. With this information, owners can fix malfunctioning sensors to ensure that derating only happens when it should, helping to boost turbine AEP and revenue.

Export limitations

Wind power is making up an increasing share of the energy mix fed into the grid. However, many legacy grids have been designed to handle conventional power sources such as coal, and struggle to handle the intermittent supply generated by renewable sources.

While steps are being taken to update the grid to better manage intermittent, distributed energy sources, wind farm owners and operators are often required to derate their assets when the grid is at capacity. It can sometimes be the case that the wind farm's output is already below the threshold for grid capacity, rendering the application of a derating strategy unnecessary. Likewise, if derating continues after the agreed export limitation time is up, the wind farm is producing a fraction of its potential, even when the grid can handle the full output.

Once owners are armed with the data to demonstrate how a derating plan has led to an unnecessary loss in generation, they can renegotiate the terms of the plan with their turbine manufacturer and grid operator, limiting any lost revenue to only what is necessary.

Legacy curtailment

Owners often have their derating strategy set up far in advance of operations, never revisiting the plan to see whether the terms remain valid in the real world.

During commissioning, for example, wind farms are often required to limit performance to prevent feeding into the grid when it is at capacity, and to minimize disruption to the surrounding environment. Noise curtailment is a common requirement; if a turbine produces more noise than permitted near residences, wind farm owners may be required to pay compensation - and risk losing support in the local community.

Over the course of a turbine's lifetime, the grid may be updated to support a greater proportion of renewable energy generation. As the surroundings of the wind farm change, the noise curtailment plan may become redundant. When this happens, it is crucial to update derating plans to reflect these changes.

Investigating unknowns

Identifying a single underperforming wind turbine is relatively easy. Incorrect farm-wide derating, however, is much more difficult to identify and significantly more costly. AI can identify wind farm-wide derating by looking for patterns and performance anomalies, comparing them to how the wind farm has previously performed, and informing the owner of how to rectify this.

Identifying a single underperforming wind turbine is relatively easy. Incorrect farm-wide derating, however, is much more difficult to identify and significantly more costly. AI can identify wind farm-wide derating by looking for patterns and performance anomalies, comparing them to how the wind farm has previously performed, and informing the owner of how to rectify this.

Reducing turbine performance to allow for grid limitations, reduce wear-and-tear on components, or reduce noise is often necessary. Derating is a strategy that wind farm owners both accept and encourage on occasion. However, if the reason for derating is defunct, or the assets are overly derated due to a technical error, owners will continue to face unnecessary losses to revenue.

In short, owners must focus on developing a true understanding of their asset's performance and, as part of this, ask themselves: Is this asset performing as it should be? If the answer is anything but a firm "yes", then an in-depth, AI-mediated analysis of data from both the asset and the surrounding environment must be prioritized. This level of understanding provides owners and operators with the information they need to review their derating strategy, and ensure they are not needlessly losing out on potential revenue.

Gareth Brown is CEO of Clir Renewables, a renewable energy AI software company. He is an entrepreneur and a chartered engineer with the IMechE. Gareth has over a decade of experience in the industry which spans the life cycle of renewable energy projects from identification, development, construction, to financing, and operation. Gareth set up Clir Renewables in 2017 alongside Jake Gray. Headquartered in Vancouver, Canada, the company opened its European office in Glasgow, Scotland, in 2018, and supports 6 GW of assets globally.

Gareth Brown is CEO of Clir Renewables, a renewable energy AI software company. He is an entrepreneur and a chartered engineer with the IMechE. Gareth has over a decade of experience in the industry which spans the life cycle of renewable energy projects from identification, development, construction, to financing, and operation. Gareth set up Clir Renewables in 2017 alongside Jake Gray. Headquartered in Vancouver, Canada, the company opened its European office in Glasgow, Scotland, in 2018, and supports 6 GW of assets globally.

Clir Renewables | clir.eco

Author: Gareth Brown

Volume: 2020 March/April

.jpg?r=5253)