Fighting Water Scarcity & Climate Change with Sustainable Mining Technology

This piece is a follow-up to Jared Lazerson's 2017 byline for North American Clean Energy.

2018 was a watershed year for the energy storage and electric vehicle sectors. The cost of solar and wind continued to decrease, while adoption of energy storage and electric vehicles reached new highs. From California's SB100, to federal electric vehicle mandates in France and China, the continuing growth and consumer demand for these technologies - and the lithium batteries that power them - has only become more certain. Similarly, the most recent National Climate Assessment clarified the scientific imperative for decarbonization. The industry has yet to reach a consensus on the ability of lithium supply to meet the growing demand. Yet, even the most bearish estimates project scarcity and supply bottlenecks within the next decade, which threaten to hinder wider adoption of clean energy and technology for price-sensitive consumers.

Technologies that can open up new sources of lithium are an important step towards achieving a more stable lithium market - but change at the periphery of the industry won't be enough. Now, it seems the largest mining companies may not have a choice in the matter. As regulators in South America (where over half of the world's lithium reserves can be found) begin to crack down on water usage, it's both economically and environmentally imperative that we bring cleantech innovation to the heart of the lithium industry. In doing so, we can address the environmental, social, and market concerns facing the lithium industry.

The shortcomings of legacy extraction methods in South America

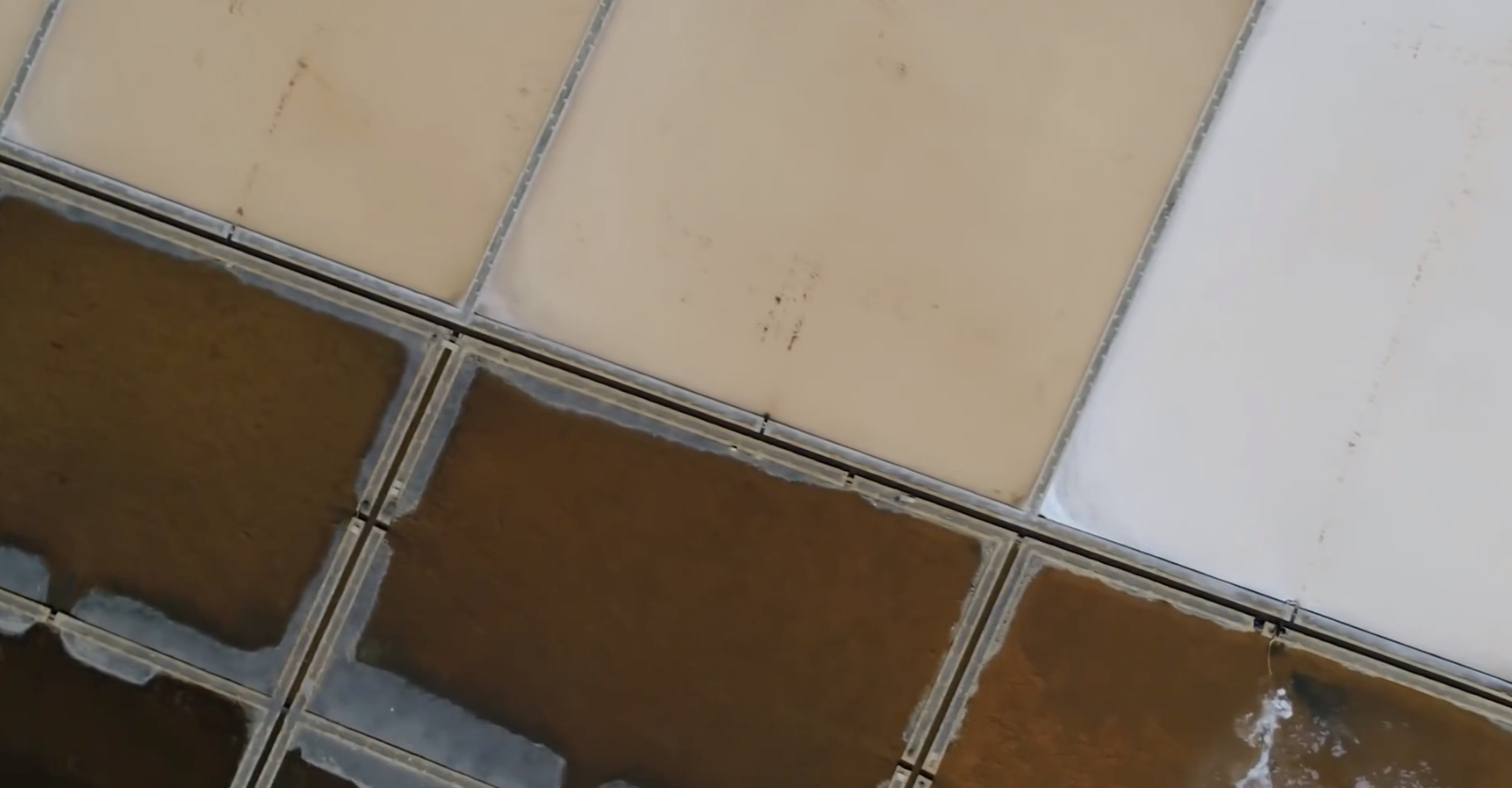

The most common method of extracting lithium in South America is a process called solar evaporation, thanks to the plentiful and highly concentrated saltwater flats, or salars, famously found in Chile, Argentina, and Bolivia. The solar evaporation process uses the sun to evaporate water from salarsin ponds that take up hundreds of acres of land.

The process of solar evaporation is highly capital and water-intensive. Extracting a single ton of lithium using solar evaporation can require as much as 500,000 gallons of water. At one plant in Argentina, wells pump at a rate of more than 2 million gallons of water per day. In addition to their large environmental footprints, these ponds cost tens of millions of dollars, and take several years to bring online. Once active, the ponds can take up to 18 months to produce any usable lithium, an inefficient pace which has led to ongoing market concerns about the viability of the lithium supply chain. Given the environmental and market imperatives to create a stable lithium supply chain, it is clear that there must be a paradigm shift in the industry that moves us away from relying on solar evaporation, particularly with vulnerable peoples facing the brunt of growing global demand.

The case for a paradigm shift in lithium mining

The issue of water scarcity in areas where lithium is mined is not a new problem. One such lithium hotspot, the Salar de Atacamain Chile, is already one of the driest places on Earth, receiving an average of less than four millimeters of rain per year. Due to the growing demand for lithium, the water shortage has become so severe for several communities in the area that they now must truck in potable water from elsewhere in the country to survive. With predictions of skyrocketing lithium demand, the communities in the Atacama, and others like it across the lithium triangle cannot sustain the industry without a change from the status quo.

Fortunately, policymakers in the region are making moves to address the water shortages. As policies incentivizing electric vehicles and clean energy have ramped up over the past year, so have policies attempting to address the environmental concerns behind lithium mining. In October of 2018, Chile began a first-of-its-kind legislative effort to restrict water usage by lithium miners, citing the intense freshwater needs for the evaporation ponds used in solar evaporation. The government blocked Albemarle, the one of the largest lithium producers in both the region and world, from building a plant to process 42,500 tons of lithium carbonate. According to the Chilean government, Albemarle "had failed to provide requested details about how it plans to triple lithium production from Chile's Salar de Atacama without using more water." Though Albemarle is challenging the government's ruling, they also face investors and industry analysts who question how the industry will be able to meet growing demand without the ability to increase lithium production in the region.

The solution: new technology, new lithium supplies

Over the past two years, new technological advances have begun to open up new sources of lithium - for example, extracting petrolithium from industrial wastewater - in order to both meet demand, and help avoid the impacts of mining facing the indigenous communities. Many companies, both from within and outside of the mining industry, are driving technology to extract lithium from these lithium-rich salars without using freshwater evaporation ponds.

Advanced nanofiltration technology, which can extract lithium and purify toxic oil sands wastewater, is also able to extract lithium from the lithium-rich salars. This technology, currently operating in oil and gas operations in North America, has the potential to completely change the way lithium is extracted in South America. Advanced nanofiltration extracts lithium from brine more rapidly than solar evaporation, producing lithium in less than 12 hours, compared to the 12 to 18 months required by traditional methods. Advanced nanofiltration also requires less capital to bring online, and is less damaging to the local environment than solar evaporation. By applying this technology and others like it, brine previously containing lithium can also be safely recycled or returned to the environment.

As lithium demand continues to grow with the increased adoption of clean energy, reliance upon traditional extraction methods threatens not only the mining industry and the local communities it impacts, but everyone with a stake in a clean energy future. It's time for industry and policymakers to work together to build the sustainable energy supply chain needed to power a truly sustainable future.

Jared Lazerson is President, CEO and Director of MGX Minerals, a developer of lithium, magnesium and silicon projects using innovative processes to supply the new energy economy.

Mr. Lazerson has worked in the mining and technology industries since 1994, with companies including Osprey Systems (GPS and Digital Mapping), United Helicopters, Copper Island Mines and Manto Resources. He holds a BA in International Relations from the University of Pennsylvania.

MGX Minerals | www.mgxminerals.com

Author: Jared Lazerson

Volume: 2019 May/June